Method for preparing silicone carbide fibre by thermochemical crosslinking and crosslinking apparatus therefor

A silicon carbide fiber, thermochemical cross-linking technology, applied in the direction of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of low oxygen content in fibers, complex process, expensive equipment, etc., achieve less consumption, simple process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

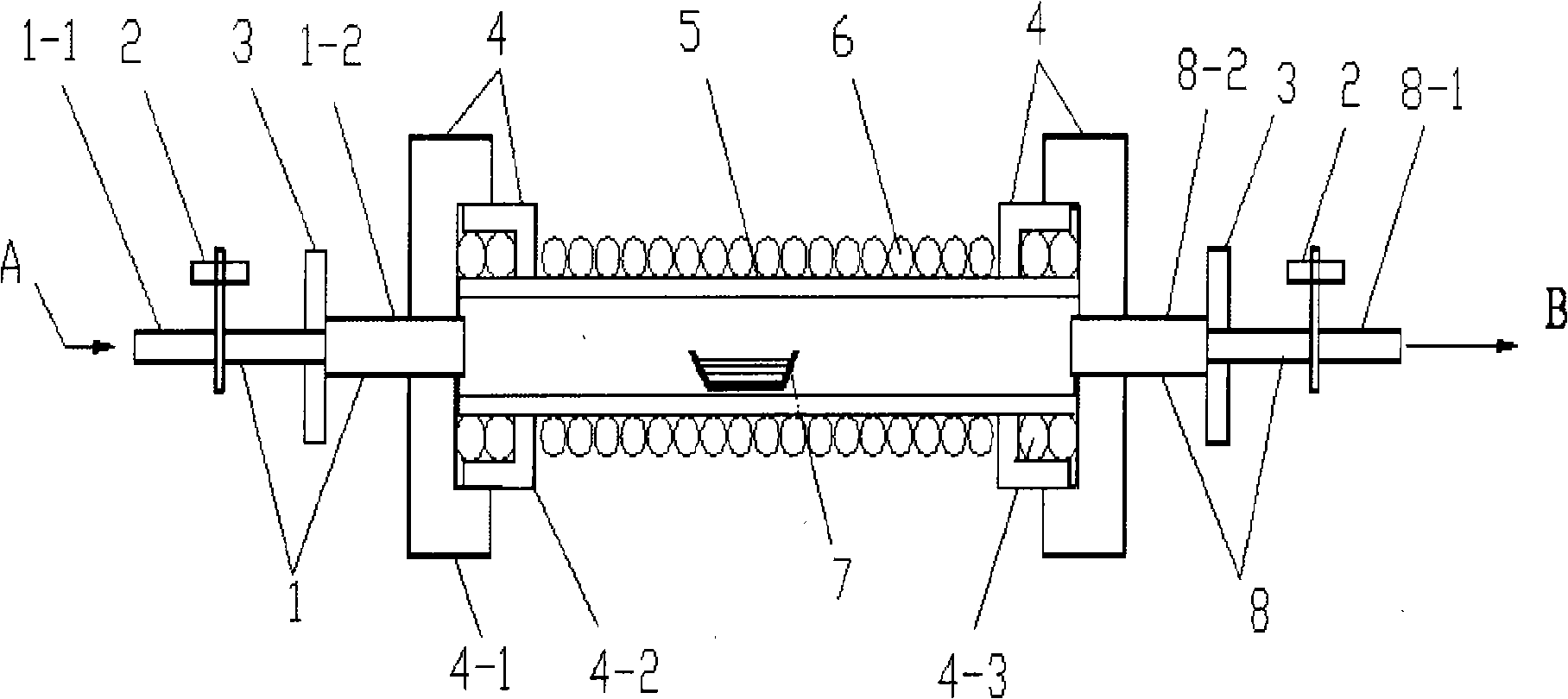

[0023] Such as figure 1 As shown, the cross-linking device includes an inlet pipe 1, a gas flow control valve 2, a flange 3, a sealing steel sleeve 4, a quartz glass tube 5, a heating coil 6, a quartz boat 7 and an air outlet pipe 8, and the heating coil 6 is set on the quartz glass Outside the pipe 5, the air inlet pipe 1 and the air outlet pipe 8 are respectively connected to both ends of the quartz glass pipe 5 through the sealed steel sleeve 4, and the quartz boat 7 is placed in the quartz glass pipe; the sealed steel sleeve includes an inner steel sleeve 4-1 with external threads and the outer steel sleeve 4-2 of the internal thread, the sealing ring 4-3 is used to seal between the inner steel sleeve 4-1 and the outer steel sleeve 4-2; the air intake pipe 1 and the air outlet pipe 8 are respectively composed of two sections of large diameter and small diameter One end of the large-diameter pipe 1-1, 8-1 is connected to the outer steel sleeve 4-2 of the sealed steel sleeve...

Embodiment 2

[0033] Technological process is with embodiment 1. The content of water in THF is 0.08%, cross-linking agent adopts aluminum isopropoxide (AIP), the mass ratio of PCS and AIP is 100: 0.5, and AIP consumption is 5mg, and the total amount of THF is 17ml, and the average molecular weight of PCS is 2800 , the viscosity of the spinning slurry reaches 20Pa.s, the number of holes in the spinneret is 200, and the average diameter of each hole is 80μm. The spinning speed is 400m / s, the average diameter of the PCS precursor is 30μm, the cross-linking protective gas is nitrogen, the purity is 99.9%, and the gas flow rate is 1000L / min. The crosslinking temperature is controlled at 260°C, the crosslinking time is 20hrs, and the PCS crosslinked fiber with a weight loss rate of 2.68% and a crosslinking degree of 73.06% is obtained; the high-temperature furnace uses high-purity nitrogen as a protective gas with a purity of 99.9%. The heating rate is 2500L / min, the heating rate is 10℃ / min bel...

Embodiment 3

[0036] Technological process is with embodiment 1. The content of water in THF is 0.08%, cross-linking agent adopts titanium isopropoxide (TIP), the mass ratio of PCS and TIP is 100: 0.2, and TIP consumption is 2mg, and the total amount of THF is 22ml, and the average molecular weight of PCS is 3600 , the viscosity of the spinning slurry reaches 28Pa.s, the number of holes in the spinneret is 20, and the average diameter of each hole is 80μm. The spinning speed is 800m / s, the average diameter of the PCS precursor is 22μm, the cross-linking protective gas is nitrogen, the purity is 99.999%, and the gas flow rate is 200L / min. The crosslinking temperature is controlled at 180°C, the crosslinking time is 6hrs, and the PCS crosslinked fiber with a weight loss rate of 0.06% and a crosslinking degree of 6.2% is obtained; the high-temperature furnace uses high-purity nitrogen as a protective gas with a purity of 99.999%. 1500L / min, the heating rate is 15°C / min below 400°C and above 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com