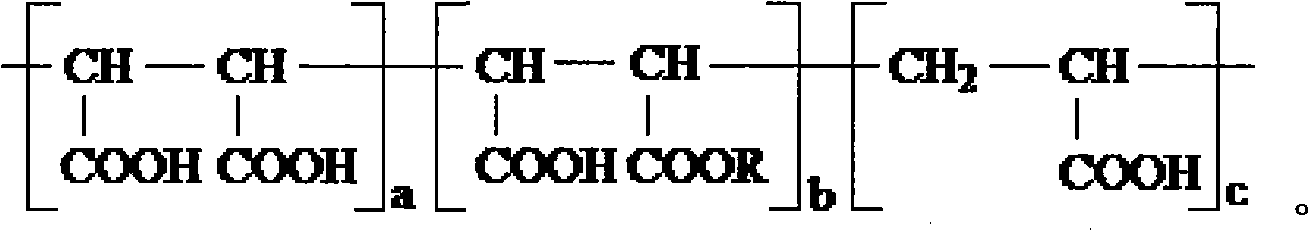

Scale-inhibiting dispersant for industry recirculated cooling water process and preparation thereof

A scale inhibitor and dispersant, the technology of circulating cooling water, applied in water/sludge/sewage treatment, chemical instruments and methods, scale removal and water softening, etc. problem, to achieve the effect of strong scale inhibition and dispersing ability, good effect and high content of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Take maleic anhydride and monohydric alcohol C with carbon number≤3 according to the molar ratio of 1:1 n h 2n+1 Mix OH with OH, carry out esterification at 80°C, and generate maleic acid monoester after esterification for 1 hour; take maleic anhydride, the above-mentioned maleic acid which can be hydrolyzed to generate equimolar maleic acid according to the monomer molar ratio of 2:1:1 Copolymerization of acid monoester and acrylic acid, using ammonium ferrous sulfate and 30% hydrogen peroxide to initiate catalysis, the mass ratio of hydrogen peroxide and maleic anhydride is 1:2, and the amount of ammonium ferrous sulfate is 0.5% of the mass of maleic anhydride ; Molecular weight regulator isopropanol is added, and the mass ratio of isopropanol, water and maleic anhydride is 1:1.2:4. The operation method of the above-mentioned copolymerization step is as follows: add maleic anhydride, maleic acid monoester, ferrous ammonium sulfate, isopropanol and water wh...

Embodiment 2

[0018] Embodiment 2: Take maleic anhydride and monohydric alcohol C with carbon number≤3 according to the molar ratio of 1:1 n h 2n+1 OH mixed, esterified at 100°C, maleic acid monoester was formed after esterification for 1 hour; according to the monomer molar ratio of 2:1.25:0.75, the maleic anhydride, the above-mentioned maleic acid which can be hydrolyzed to generate equimolar maleic acid Copolymerization of acid monoester and acrylic acid, using ammonium ferrous sulfate and 30% hydrogen peroxide to initiate catalysis, the mass ratio of hydrogen peroxide and maleic anhydride is 1:2, and the amount of ammonium ferrous sulfate is 0.5% of the mass of maleic anhydride ; Molecular weight regulator isopropanol is added, and the mass ratio of isopropanol, water and maleic anhydride is 1:1.2:4. The operation method of the above-mentioned copolymerization step is as follows: add maleic anhydride, maleic acid monoester, ferrous ammonium sulfate, isopropanol and water which can be h...

Embodiment 3

[0019] Embodiment 3: Take maleic anhydride and monohydric alcohol C with carbon number≤3 according to the molar ratio of 1:1 n h 2n+1 OH mixed, esterified at 110°C, maleic acid monoester was formed after esterification for 1 hour; according to the monomer molar ratio of 2:1.5:0.5, the maleic anhydride, the above-mentioned maleic acid which can be hydrolyzed to generate equimolar maleic acid Copolymerization of acid monoester and acrylic acid, using ammonium ferrous sulfate and 30% hydrogen peroxide to initiate catalysis, the mass ratio of hydrogen peroxide and maleic anhydride is 1:2, and the amount of ammonium ferrous sulfate is 0.5% of the mass of maleic anhydride ; Molecular weight regulator isopropanol is added, and the mass ratio of isopropanol, water and maleic anhydride is 1:1.2:4. The operation method of the above-mentioned copolymerization step is as follows: add maleic anhydride, maleic acid monoester, ferrous ammonium sulfate, isopropanol and water which can be hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com