Novel sinking hoist

A hoist and well-sinking technology, applied in the field of new well-sinking hoist, can solve the problems such as easy change of gear spoke tooth side clearance, oil leakage from a rope adjusting oil cylinder or interlock valve, affecting the safe operation of the hoist, etc. Axial string movement, fast and accurate rope adjustment, safe and reliable braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

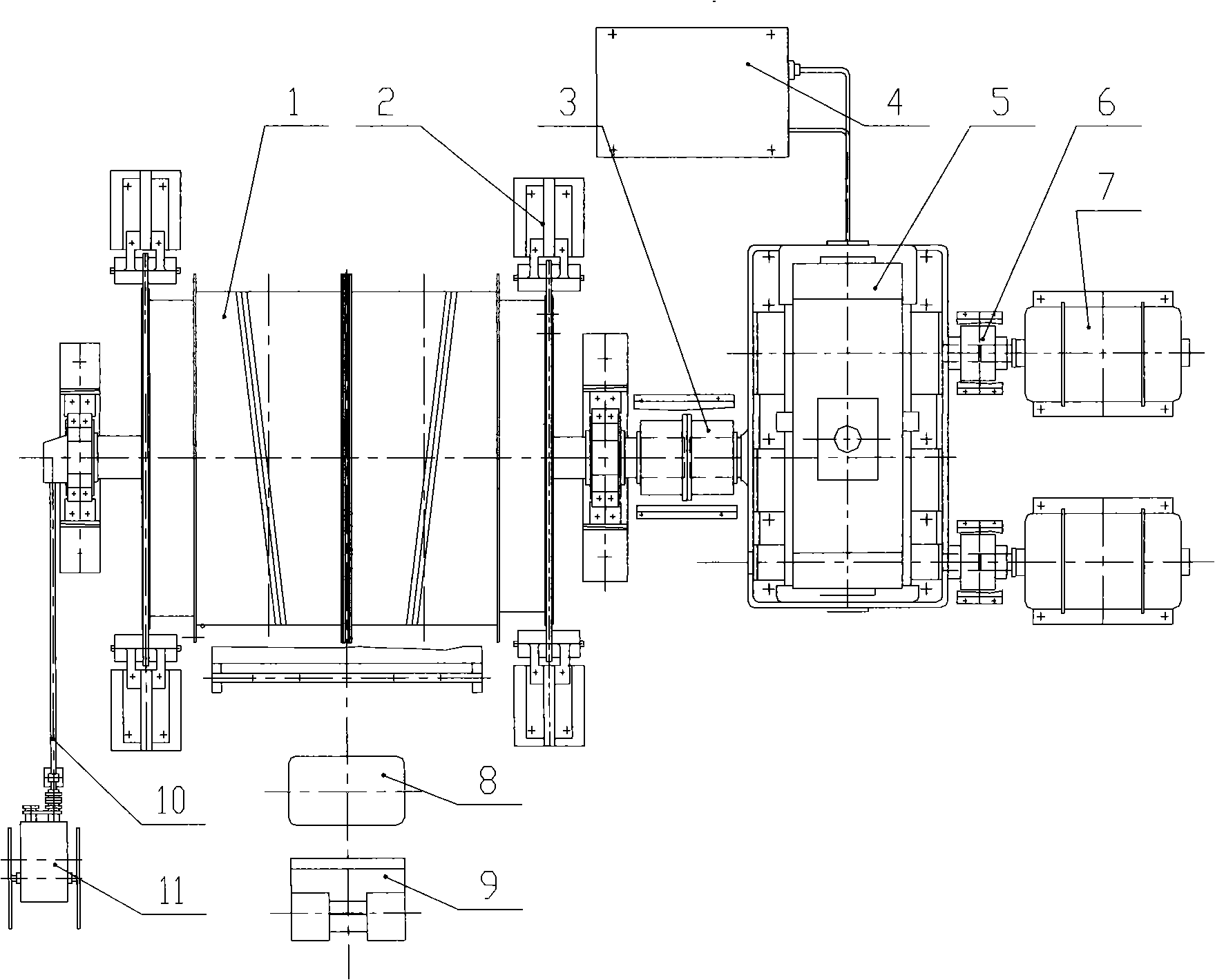

[0030] Such as figure 1 Shown: the dual input shafts of the reducer (5) in the novel sinking hoist of the present invention are connected to two motors (7) through an elastic pin coupling (6), and the output shafts of the reducer (5) are coupled through gears The device (3) is connected to the fixed main shaft device (1), and four disc brake devices (2) are arranged symmetrically on the left and right on the main shaft device (1), and the idle end of the main shaft device (1) is connected with an archway-type depth indicator The transmission device (12), the transmission device (10) is connected with the arch type depth indicator (11) to monitor the sinking depth; the above devices are controlled by the console (9), and the lubrication station (4) and the hydraulic station (8) are The new sinker hoist provides equipment lubrication and brake oil pressure.

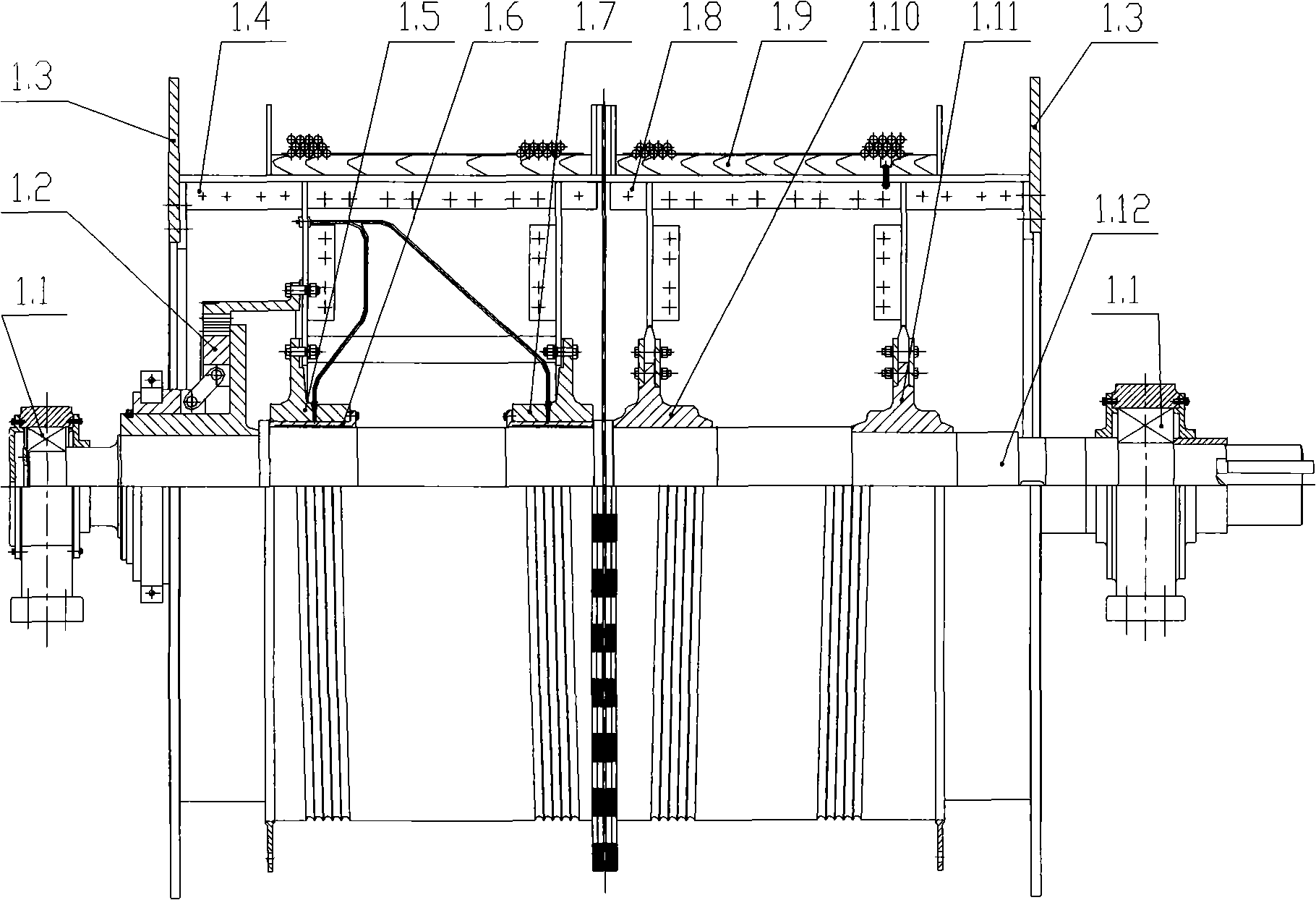

[0031] Such as figure 2 Shown: In the novel drilling hoist of the present invention, the main shaft (1.12) in the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com