Method for preparing cellulose contrast medium for stomach and intestine ultrasonic imaging

An ultrasound contrast agent, cellulose technology, applied in echo/ultrasonic imaging agents, etc., can solve the problems of short residence time, unfavorable inspection, uneven particle size, etc., and achieve the effect of eliminating artifacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

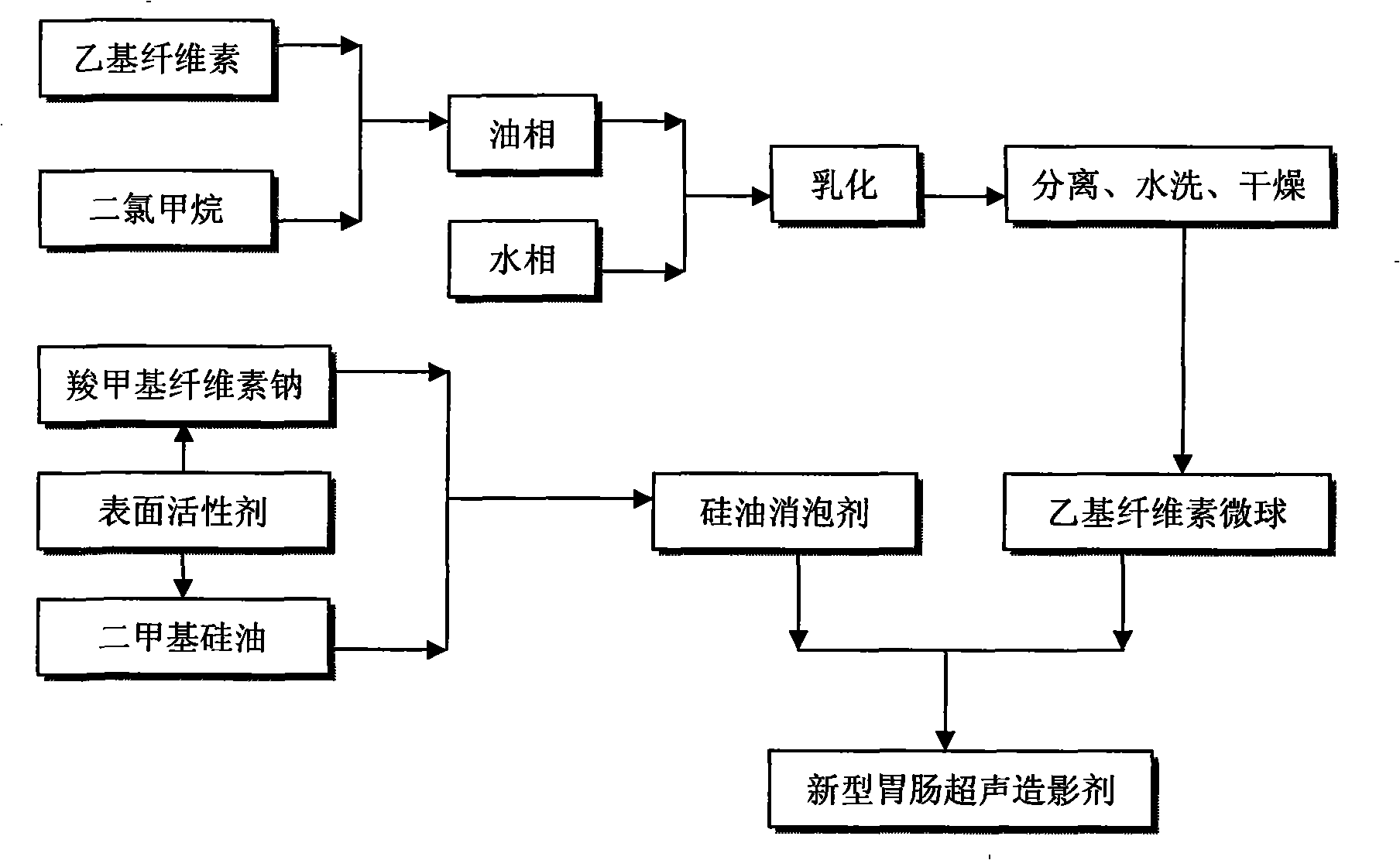

preparation example Construction

[0045] Preparation of ethylcellulose microspheres:

[0046] (1) Weighing ethyl cellulose and dissolving it in dichloromethane to prepare an organic phase with a concentration of 10-30% by mass;

[0047] (2) Weigh polyvinyl alcohol and dissolve it in distilled water to prepare an external aqueous phase solution with a concentration of 1 to 5% by mass;

[0048] (3) Add the organic phase dropwise to the external aqueous phase solution at a speed of 300-1500r / min, stir and disperse for 5-30min;

[0049] (4) After the solvent is volatilized for 2 to 8 hours at a stirring speed of 500 to 600 r / min, centrifuge and wash with water for 3 to 5 times, and dry to obtain ethyl cellulose microspheres with a particle size of 20 μm;

[0050] Preparation of silicone oil defoamer:

[0051] The silicone oil defoamer refers to medical, edible grade silicone oil and other medical, edible grade surfactants. The preparation method is as follows:

[0052] (1) Weigh carboxymethylcellulose sodium, add...

Embodiment 1

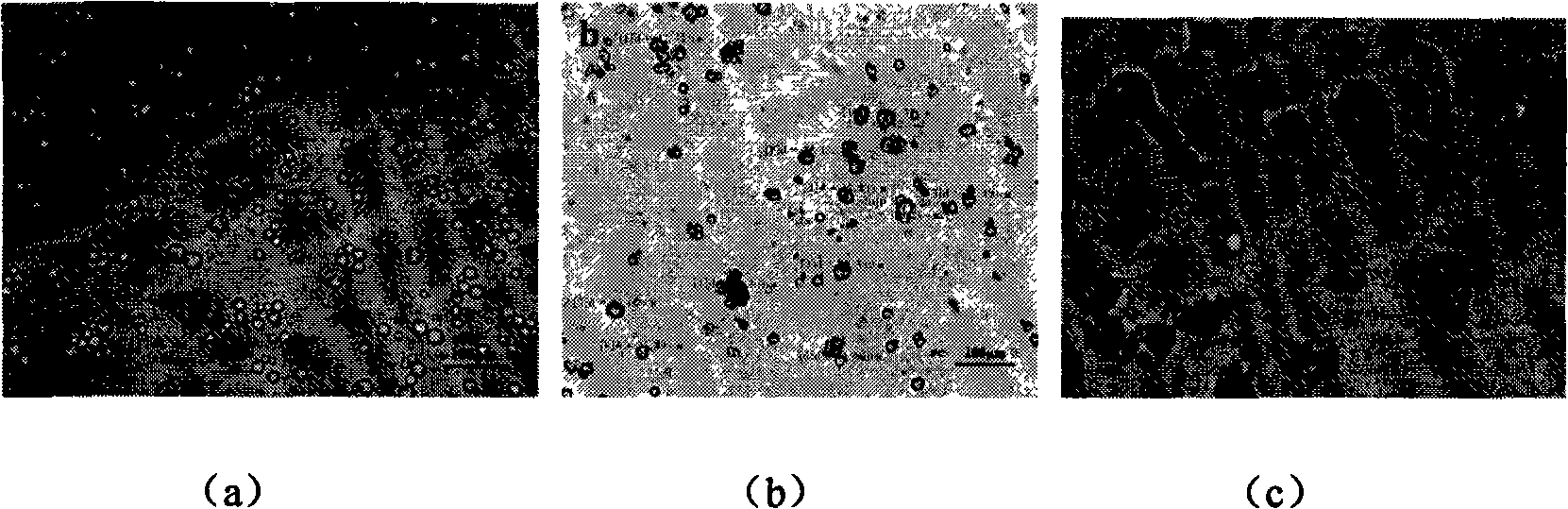

[0065] Weigh 1.0 g of ethyl cellulose and dissolve it in 10 ml of dichloromethane solution as the organic phase. At the same time, 3.0 g of polyvinyl alcohol (PVA-20) was weighed and added to 100 ml of distilled water as the external aqueous phase solution, and 2 g of Tween-60 was added thereto, and heated to dissolve. The organic phase solution was added dropwise to the external aqueous phase at a rotational speed of 800r / min, stirred for 10min, and then moved to a magnetic stirrer at a stirring speed of 500r / min, and the solvent was evaporated for 5h. The microspheres were separated by centrifugation, washed three times with distilled water, and then dried to obtain ethylcellulose microspheres after repeated three times. Observed by an optical microscope, the surface of the microspheres is smooth without adhesion, and the particle size is relatively concentrated, with an average particle size of 23.2 μm. When preparing the silicone oil defoamer, first weigh 0.5g sodium carb...

Embodiment 2

[0067] Weigh 1.0 g of ethyl cellulose and dissolve it in 15 ml of dichloromethane solution as the organic phase. At the same time, 3.0 g of polyvinyl alcohol (PVA-20) was weighed and added to 100 ml of distilled water as the external aqueous phase solution, and 0.5 g of Tween-60 and 0.5 g of Tween-80 were added thereto, and heated to dissolve. The organic phase solution was added dropwise to the external aqueous phase at a rotational speed of 1200r / min, stirred for 10min, and then moved to a magnetic stirrer at a stirring speed of 550r / min, and the solvent was evaporated for 5h. The microspheres were separated by centrifugation, washed with distilled water, repeated three times, and dried to obtain ethylcellulose microspheres. Observed by an optical microscope, the surface of the microspheres is smooth without adhesion, and the particle size is relatively concentrated, with an average particle size of 18.6 μm. When preparing the silicone oil defoamer, first weigh 0.5g sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com