Thermal optimization of a solar photovoltaic powered electrolyzer system

A technology of solar photovoltaic and electrolyzer, applied in the field of solar electrolyzer, can solve the problems of high cost and low efficiency of solar hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following description of the embodiments is merely exemplary in nature and in no way intended to limit the invention and its application or use.

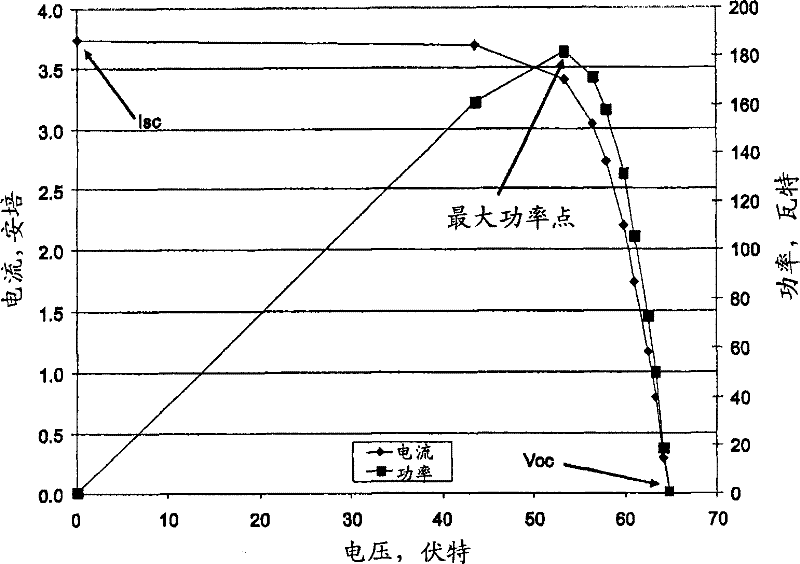

[0018] figure 1 Shown are current-voltage (I-V) curves and power-voltage curves measured for a Sanyo HIP-190BA3 module supplied by Sanyo Energy Corp. in Warren, Michigan on a sunny day. The module is pointed at the sun, using a DC load (HewlettPackard 6060A) from the open circuit voltage (V oc ) to the short-circuit current (I sc ) scan to obtain the I-V curve. Solar irradiance was measured with a United Detector Technology crystalline silicon photodiode (UDT 10 Model DP / SV) hooked up to a Fluke Model 179 multimeter that measures the mA current from the photodiode. 1000W / m 2 The UDT output current at irradiance was calibrated by the National Renewable Energy laboratory. The temperature of the module was measured by a VWR catalog number 77776-730 (Batavia, Illinois) electronic thermometer affixed to the back of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com