Pump

A fluid and vibrating plate technology, used in pumps, piston pumps, pumps with flexible working elements, etc., can solve the problems of reducing fluid discharge, diaphragm damage, inability to exert performance, etc., to achieve large discharge and restrain expansion and deformation. , the effect of increasing the amount of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

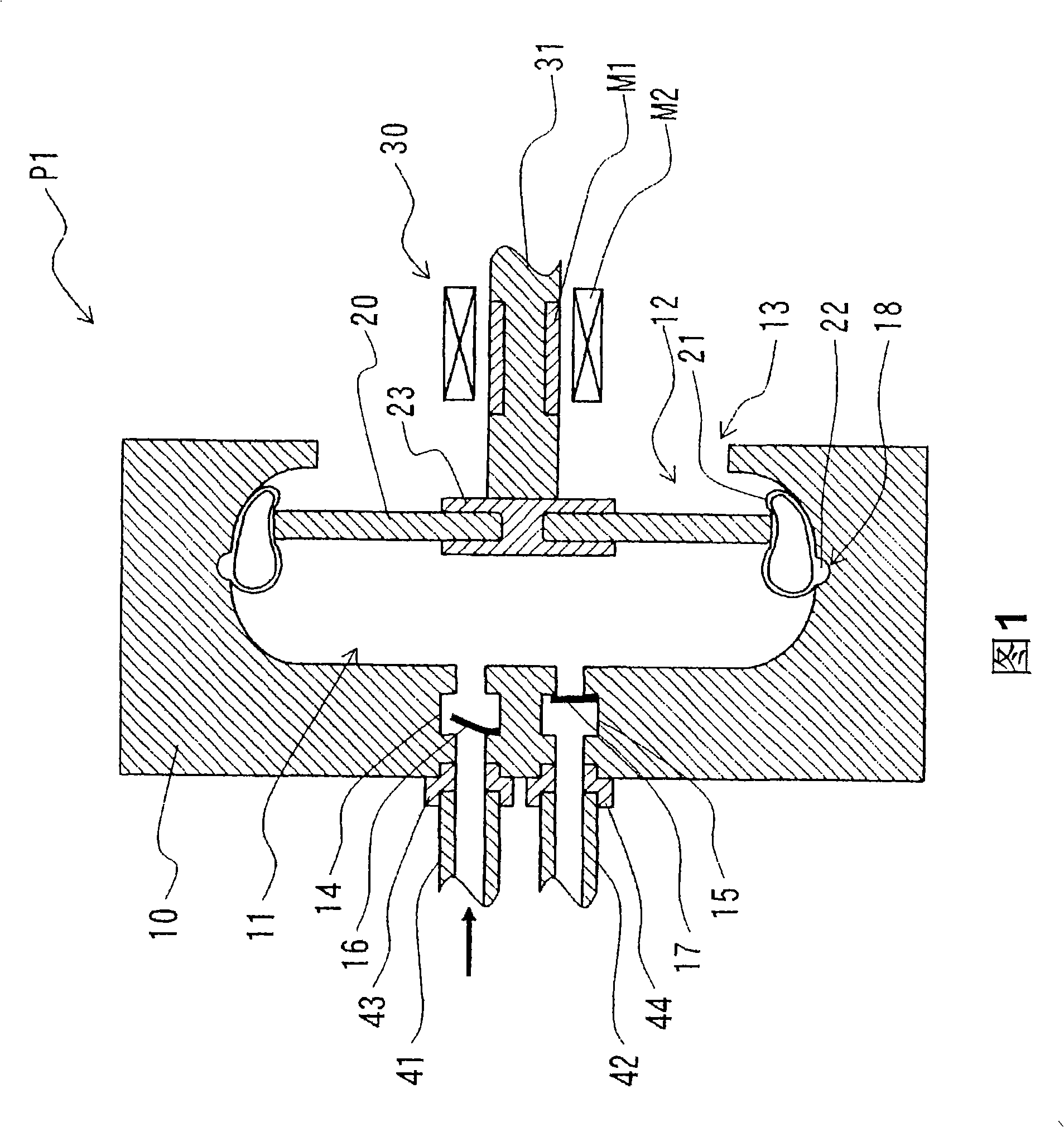

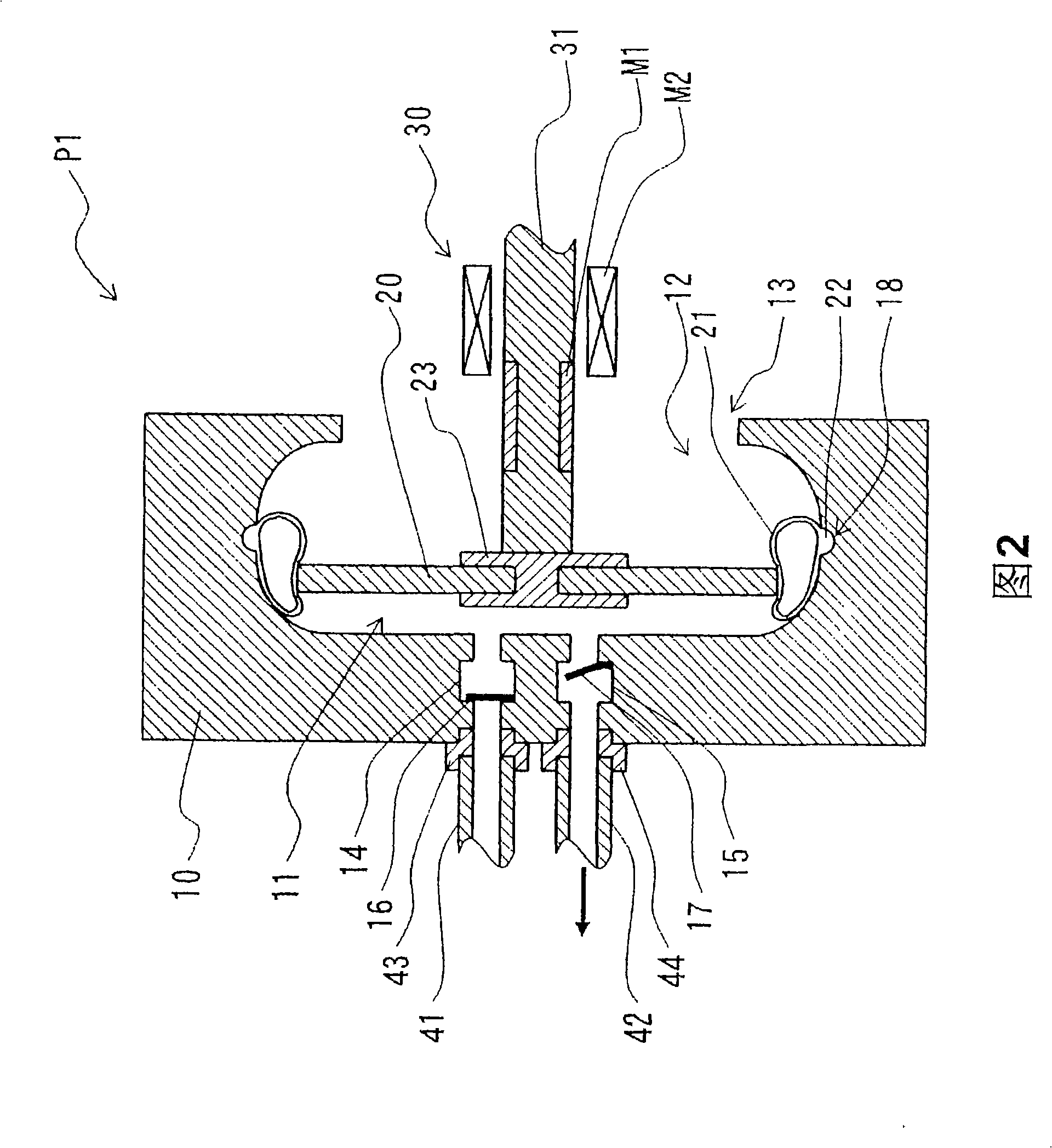

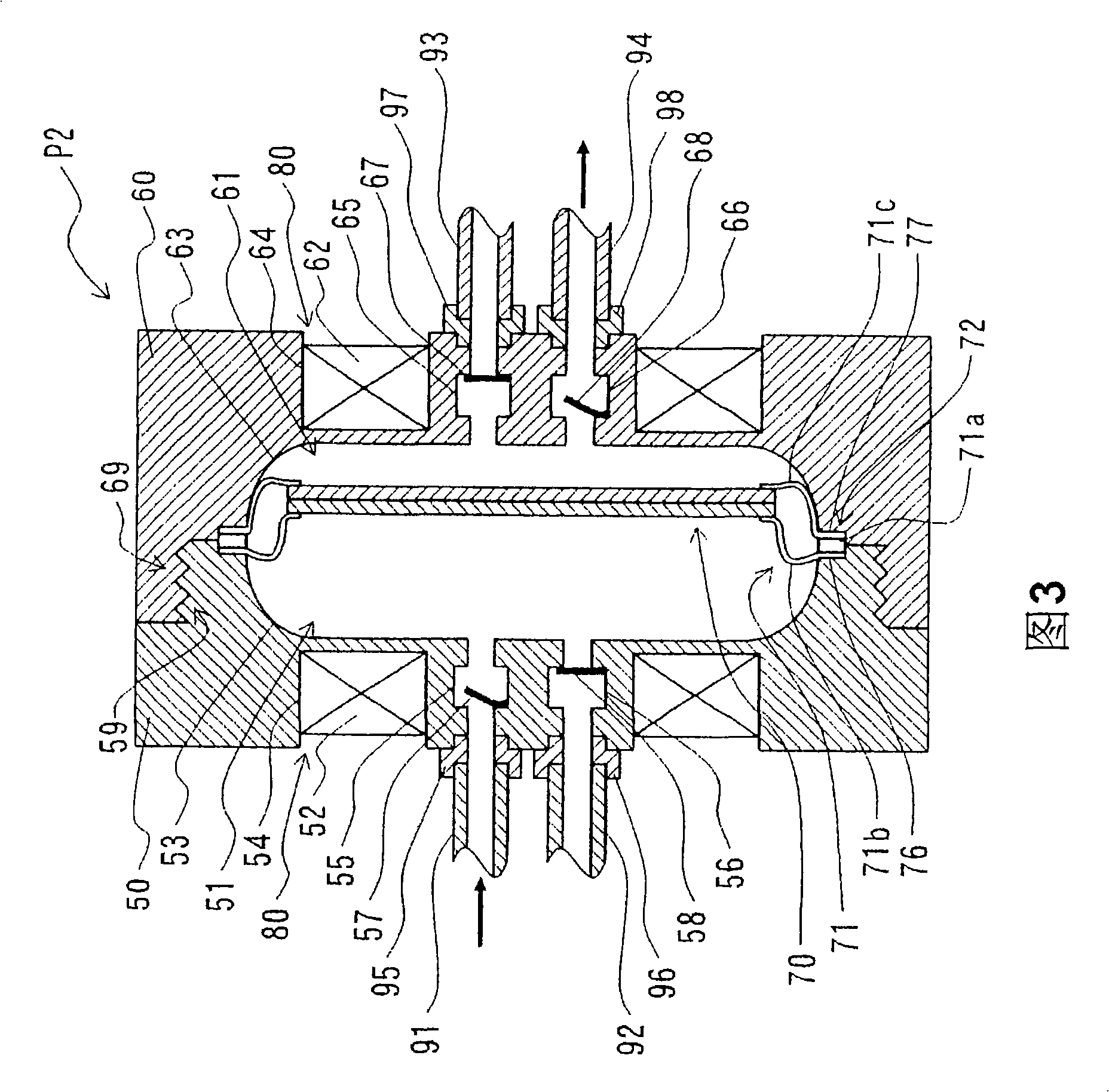

[0057] The pump of the present invention applies a predetermined pressure to feed a low-viscosity fluid such as air, and realizes a high discharge pressure of a so-called diaphragm pump.

[0058] That is to say, the pump of the present invention is the same as a common diaphragm pump, comprising: a housing with a storage chamber that connects the feed pipe and the delivery pipe respectively through the one-way valve and temporarily stores the fluid; Driving the vibrating body that sucks the fluid from the feed pipe to the storage chamber and then extruding it to the delivery pipe; and the driving part that drives the vibrating body forward and backward.

[0059] A common diaphragm pump uses a film-like diaphragm to form a vibrating body, but the present invention uses a plate with higher rigidity to form a vibrating plate.

[0060] Further, the vibrating plate is provided with an annular pipe along the outer periphery, the vibrating plate is attached to the case through the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com