Experimental device for concrete multifactor permanent stability under co-action of pulling stress and surroundings

A technology that works together and is an experimental device. It is used in measuring devices, strength characteristics, material inspection products, etc. It can solve problems such as difficult coincidence, damage at clamping, and easy eccentricity. Accurate geometry, small footprint, No stress relaxation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

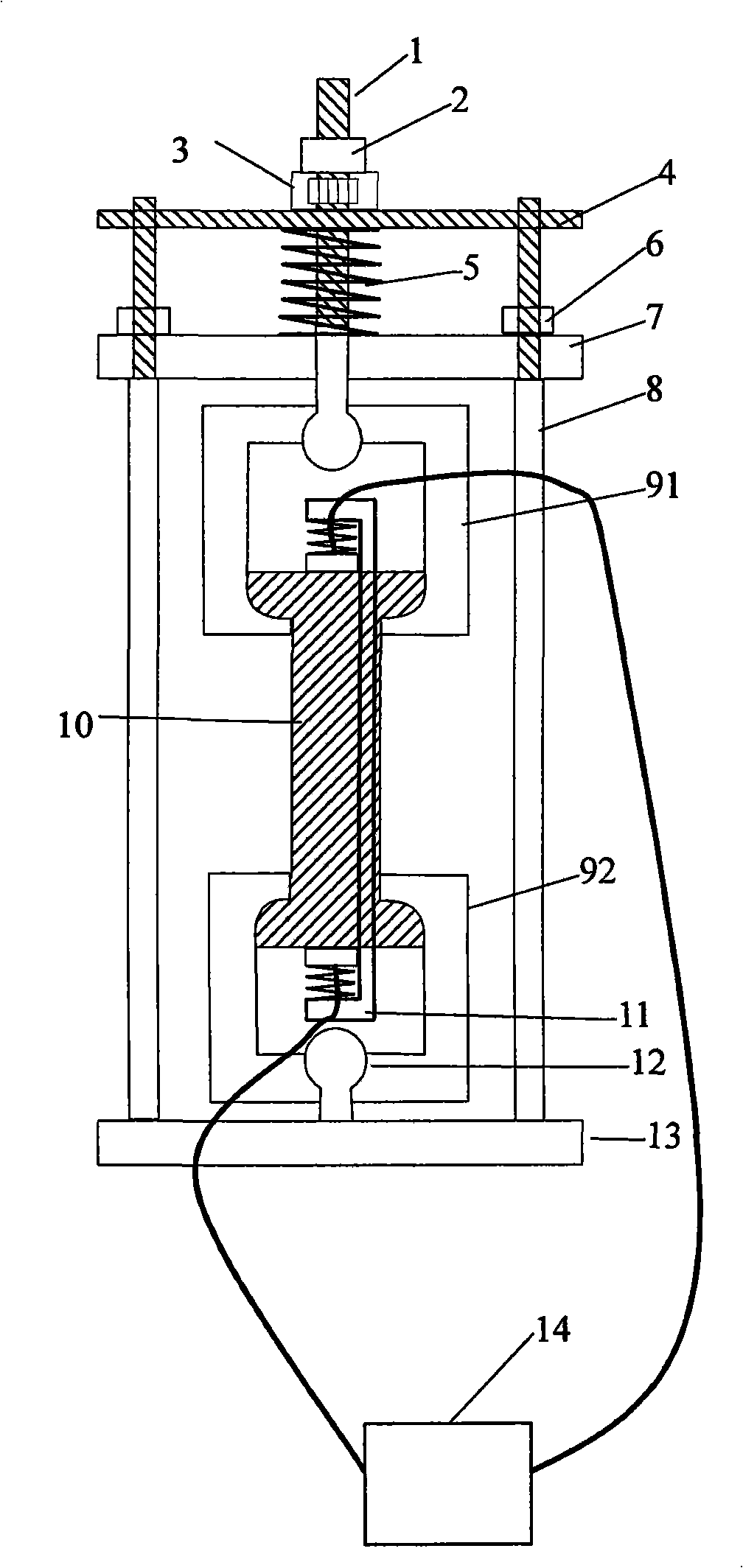

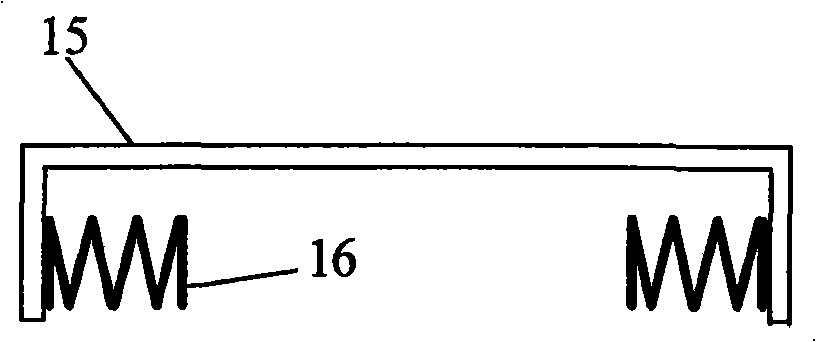

[0035]The device includes: spherical screw 1, nut 2, stress sensor 3, limit plate 4, spring 5, lock nut 6, upper pull plate 7, pull rod 8, tensile chuck, dumbbell-shaped concrete specimen 10, constant Force clamping instrument 11, spherical pull rod 12, pull-down plate 13, non-metallic ultrasonic tester 14; in this device, the lower part of pull rod 8 is connected with pull-down plate 13, and the upper part of pull rod 8 passes through upper pull plate 7 and limit plate 4 , the upper pull plate 7 is worn on the pull rod 8 and fixed by the lock nut 6, the nut 2 presses the stress sensor 3 on the limit plate 4 through the spherical screw 1, the spring 5 is set on the spherical screw 1 and is located on the limit plate 4 Between the upper drawing plate 7 and the upper drawing plate 7 and the lower plate 13, an upper drawing chuck 91 and a lower drawing chuck 92 are arranged, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com