Preparation for high-purity laver phycoerythrin with one-step chromatography

A technology of laver phycoerythrin and phycoerythrin, which is applied to the preparation method of peptides, algae/moss peptides, chemical instruments and methods, etc., can solve the problems of increasing costs and achieve the effect of improving the value of deep processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

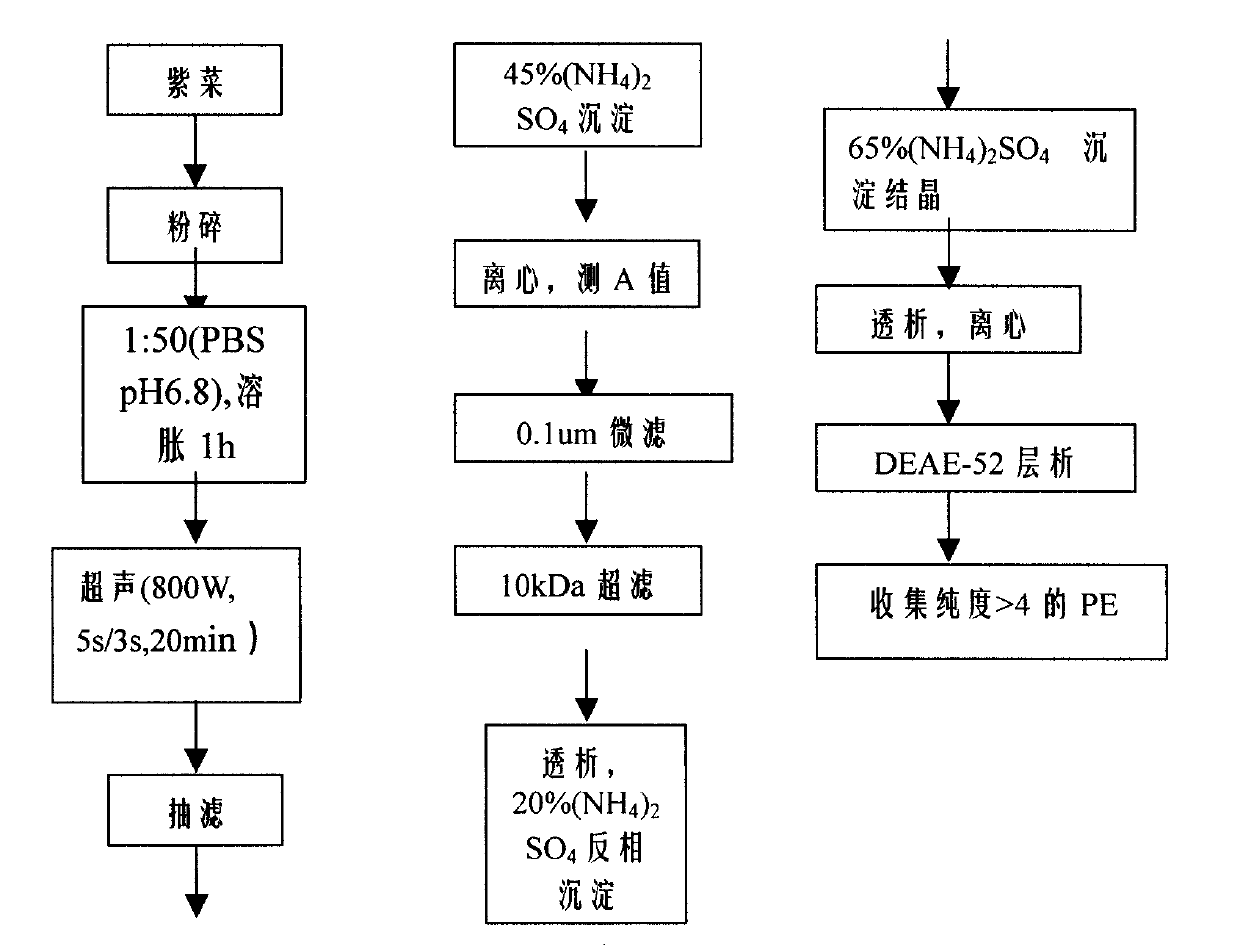

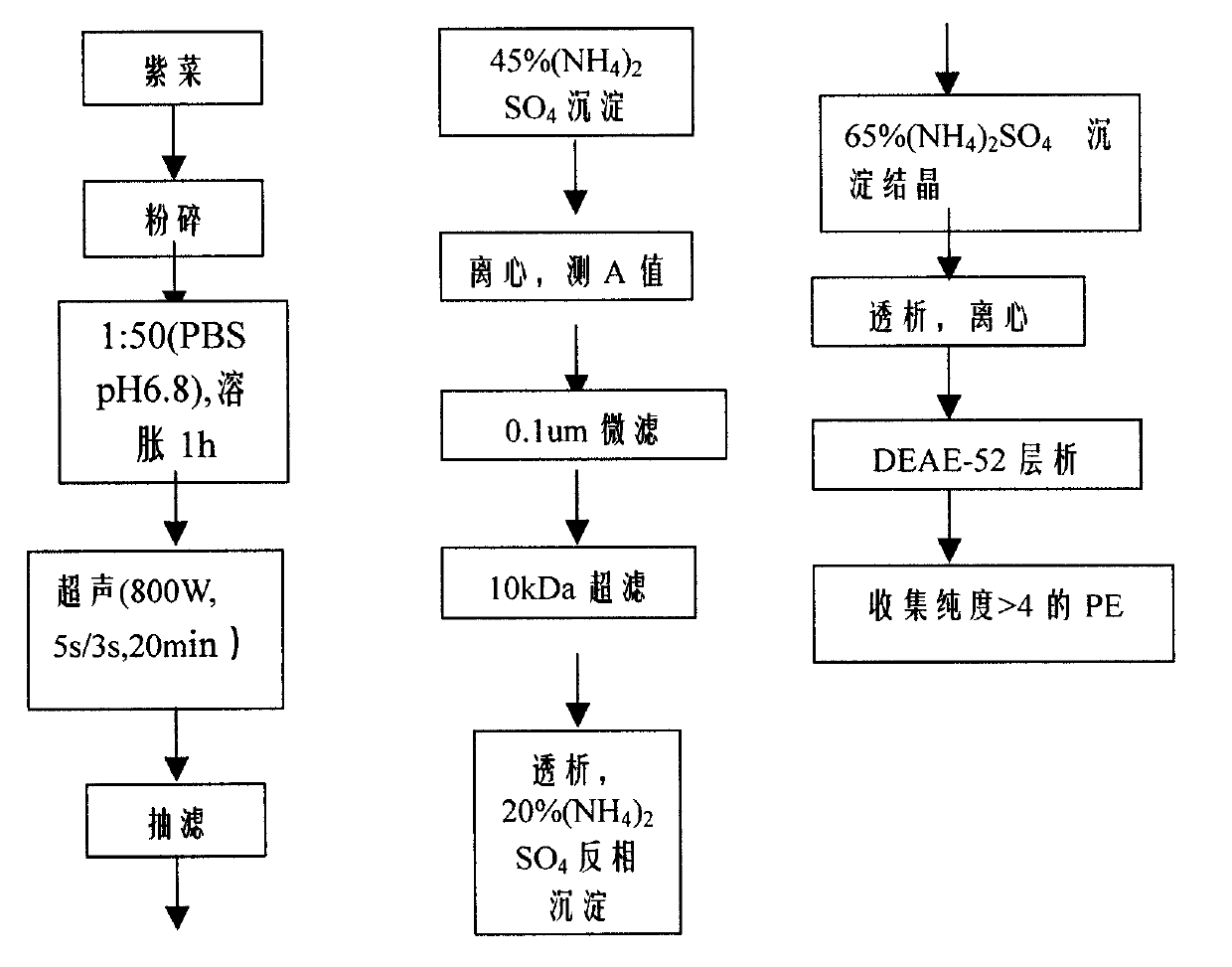

[0022] (1) Weigh 4 grams of laver powder, and soak in PBS (1 mM, pH 6.8) buffer solution at a volume ratio of 1:50 for 1 hour to fully swell. The cells were disrupted in an ice bath with 800W ultrasonic ultrasound for 20min. Centrifuge under 5000rpm for 20min to obtain crude phycoerythrin extract. Precipitate with 45% ammonium sulfate, centrifuge (5000rpm, 20min), and dissolve the precipitate in 40mL, 1mmol·L -1 In phosphate buffer (pH6.8);

[0023] (2) The phycoerythrin solution obtained by ammonium sulfate precipitation with a saturation of 45% is first filtered with a 0.1um microfiltration membrane, and then filtered and concentrated with an ultrafiltration membrane with a membrane pore size of 10KDa. Dialysis, reverse precipitation with 20% ammonium sulfate, centrifugation (5000 rpm, 20 min). Then use an efficient crystallization method to precipitate the supernatant with ammonium sulfate with a saturation of 65%, and store it for one week under 4% crystallization;

[0024] ...

Embodiment 2

[0026] (1) Weigh 4 grams of laver powder, and soak in PBS (1 mM, pH 6.8) buffer solution at a ratio of 1:50 for 1 hour to fully swell. The cells were disrupted in an ice bath with 800W ultrasonic ultrasound for 20min. Centrifuge under 5000rpm for 20min to obtain crude phycoerythrin extract. Precipitate with 45% ammonium sulfate, centrifuge (5000rpm, 20min), and dissolve the precipitate in 40mL, 1mmol·L-1 phosphate buffer (pH6.8);

[0027] (2) The phycoerythrin solution obtained by ammonium sulfate precipitation with a saturation of 45% is first filtered with a 0.1um microfiltration membrane, filtered and concentrated with an ultrafiltration membrane with a membrane pore size of 30KDa, and then a membrane with a membrane pore size of 10KDa Ultrafiltration. Dialysis, reverse precipitation with 20% ammonium sulfate, centrifugation (5000 rpm, 20 min). Then use an efficient crystallization method to precipitate the supernatant with ammonium sulfate with a saturation of 65%, and sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com