Multilevel hole material load cobalt catalyst, preparation method and application thereof

A technology of cobalt catalyst and multi-level pores, applied in the field of catalyst and preparation, can solve problems such as poor penetration, and achieve the effects of avoiding diffusion limitation, high thermal stability and hydrothermal stability, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

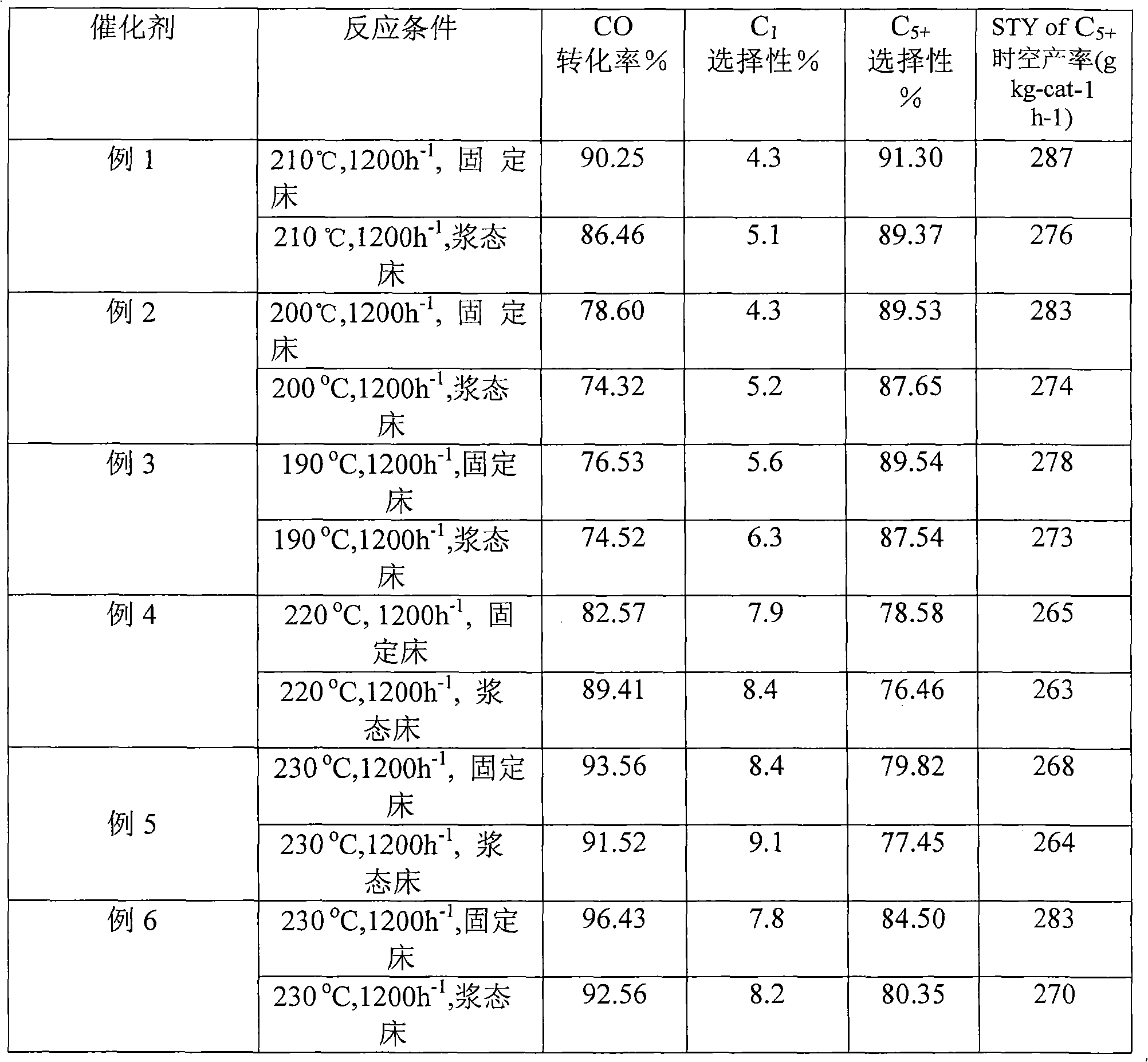

Examples

Embodiment 1

[0025] Preparation of hierarchical porous silica: commercially available popcorn with better expansion was placed in a high-temperature tube furnace, and carbonized at 900°C for 4 hours in a nitrogen atmosphere. Porous carbon with honeycomb macroporous structure and uniform microporous structure is obtained.

[0026] Prepare the solution silicon source according to the following ratio: ethanol: NH 3 :H 2 O=1:30:0.15:2, the solution was stirred at room temperature for 6 h, and then impregnated into the pores of porous carbon in three steps (porous carbon / porous carbon+solution=30 (WT%)). Immerse each step for 24 hours and dry at 100°C for 24 hours. Finally, it was calcined at 600° C. under an air atmosphere for 6 hours to remove the carbon template to obtain a hierarchically porous silica carrier.

[0027] The preparation of catalyst: take by weighing 9.3g Co(NO 3 ) 2 ·6H 2 O and 0.35g Ru(NO 3 ) 4 Dissolve in 30ml of water, impregnate the above 10g carrier, let it stand...

Embodiment 2

[0031] Preparation of hierarchical porous silica: using porous carbon material as a template, the preparation process is as follows: commercially available popcorn with good expansion is placed in a high-temperature tube furnace, and carbonized at 1000°C for 6 hours in a nitrogen atmosphere. Porous carbon with honeycomb macroporous structure and uniform microporous structure is obtained. Prepare the solution silicon source according to the following ratio: ethanol: NH 3 :H 2 O=1:25:0.12:2, the solution was stirred at room temperature for 8h, and then impregnated into the pores of porous carbon in four steps (porous carbon / porous carbon+solution=40(wt%)). Immerse each step for 12 hours and dry at 110°C for 36 hours. Finally, it was calcined at 600°C for 6 hours in an air atmosphere to remove the carbon template to obtain a hierarchically porous silica carrier.

[0032] The preparation of catalyst: take by weighing 9.3g Co(NO 3 ) 2 ·6H 2 O and 0.7g Ru(NO 3 ) 4 Dissolve in ...

Embodiment 3

[0036] Preparation of Hierarchical Porous Silica: Using porous starch gel as a template, the preparation process is as follows: Weigh 10g of potato starch into 100g of water, heat to 90°C and stir for 10min. After standing for 12h, put it in a refrigerator at -20°C After standing for 12 hours, it was dried at room temperature to obtain a porous starch gel with a regular structure. Prepare the solution silicon source according to the following ratio: ethanol: NH 3 :H 2 O=1:30:0.35:2, the solution was stirred at room temperature for 8h, and then impregnated into the pores of the starch template in four steps (starch gel / starch gel+solution=20(wt%)). Immerse each step for 24 hours and dry at 130°C for 24 hours. Finally, the carbon template was removed by calcining at 650° C. under an air atmosphere for 7 hours to obtain a hierarchically porous silica carrier.

[0037] The preparation of catalyst: take by weighing 24.6g Co(NO 3 ) 2 ·6H 2 O was dissolved in 36ml of water, imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com