Chip resistor

A chip resistor and resistor body technology, applied in resistors, thick film resistors, resistor parts and other directions, can solve problems such as adverse effects, hinder the manufacturing yield, hinder the low resistance of chip resistors 1, etc. Good manufacturing yield and the effect of securing installation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

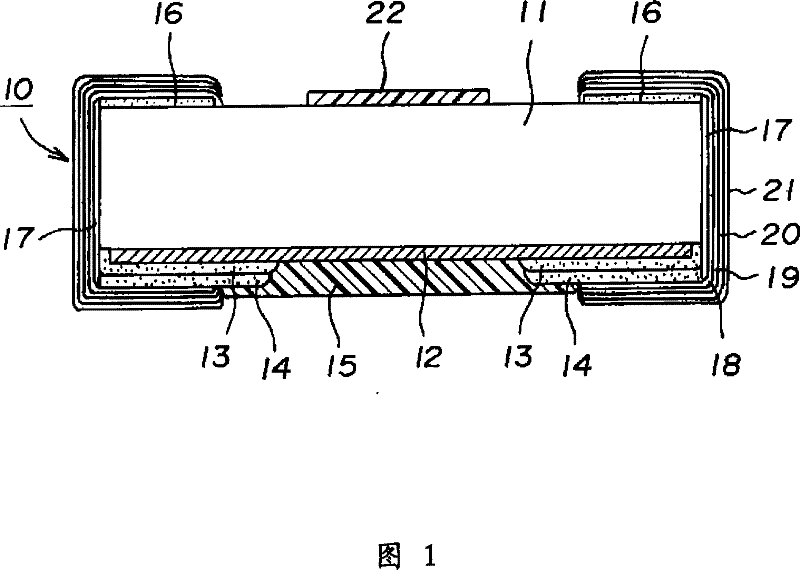

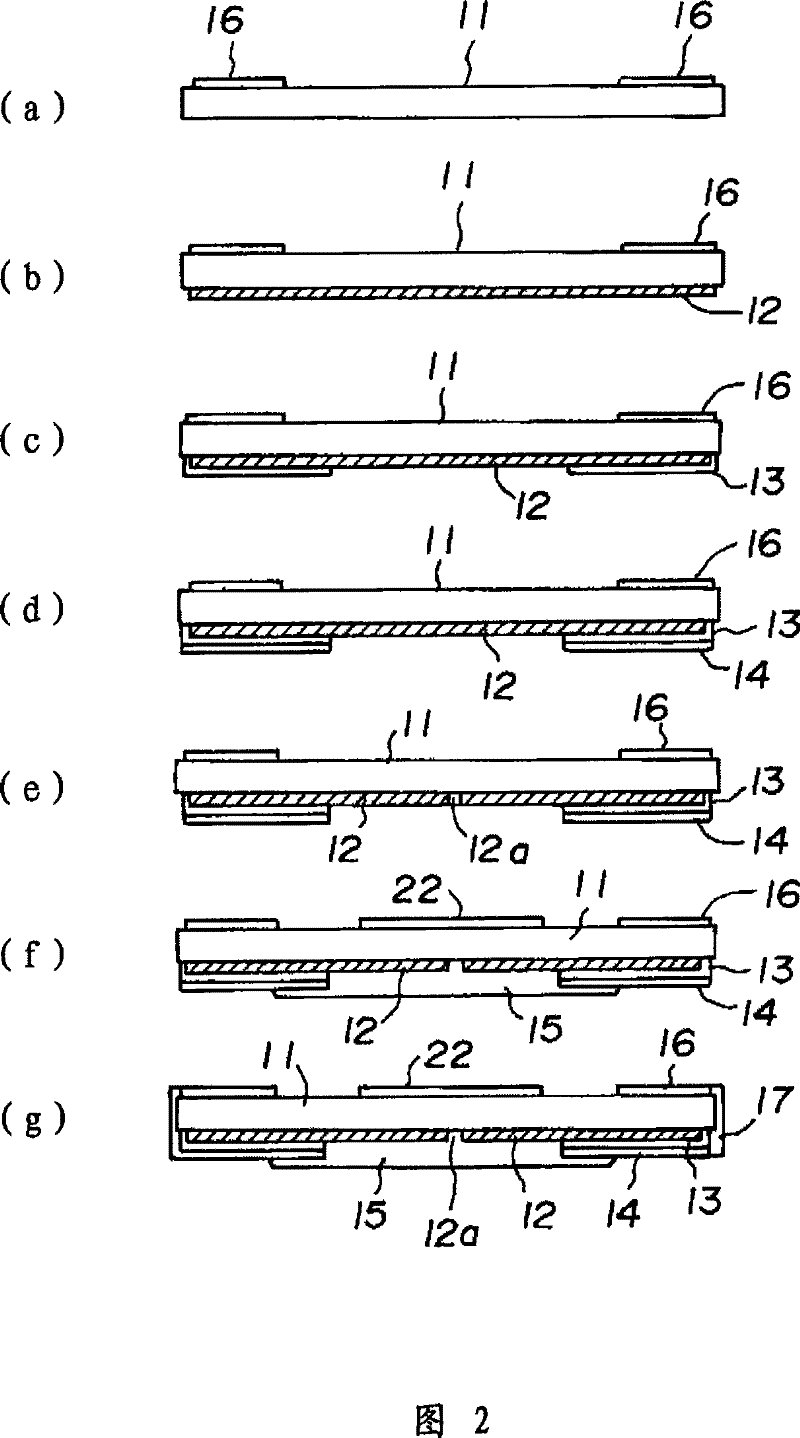

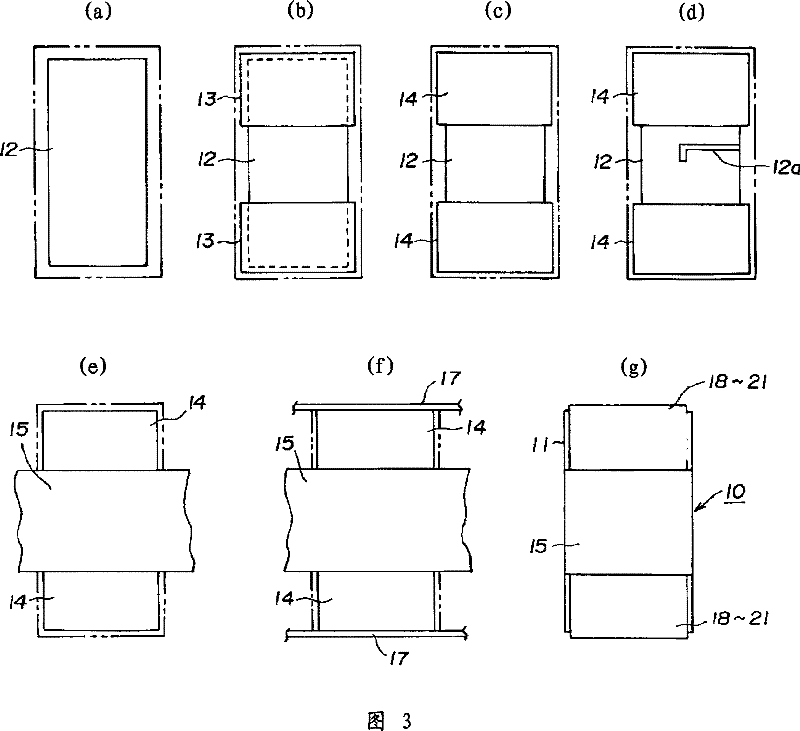

[0020] Embodiments of the invention will be described with reference to the drawings, figure 1 is a cross-sectional view schematically showing a chip resistor according to an embodiment of the present invention, figure 2 is a cross-sectional view showing the manufacturing process of the chip resistor, image 3 is a plan view showing the manufacturing process of the chip resistor, Figure 4 It is a cross-sectional view of main parts showing the state in which the chip resistor is mounted on a circuit board.

[0021] The chip resistor 10 shown in these figures is a low resistance and low TCR chip resistor mounted face down on a circuit board 30 . This chip resistor 10 is provided on the lower surface of a rectangular parallelepiped ceramic substrate 11: a resistor body 12 mainly composed of a copper / nickel alloy; The second electrode layer 13, 14; and the insulating protective layer 15 of the resistor 12 covering the area not covered by the two electrode layers 13, 14, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com