Heat radiation device

A cooling device and heat sink technology, which is applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc., can solve the problems of reducing production efficiency and assembly efficiency, and achieve the effect of convenient assembly and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

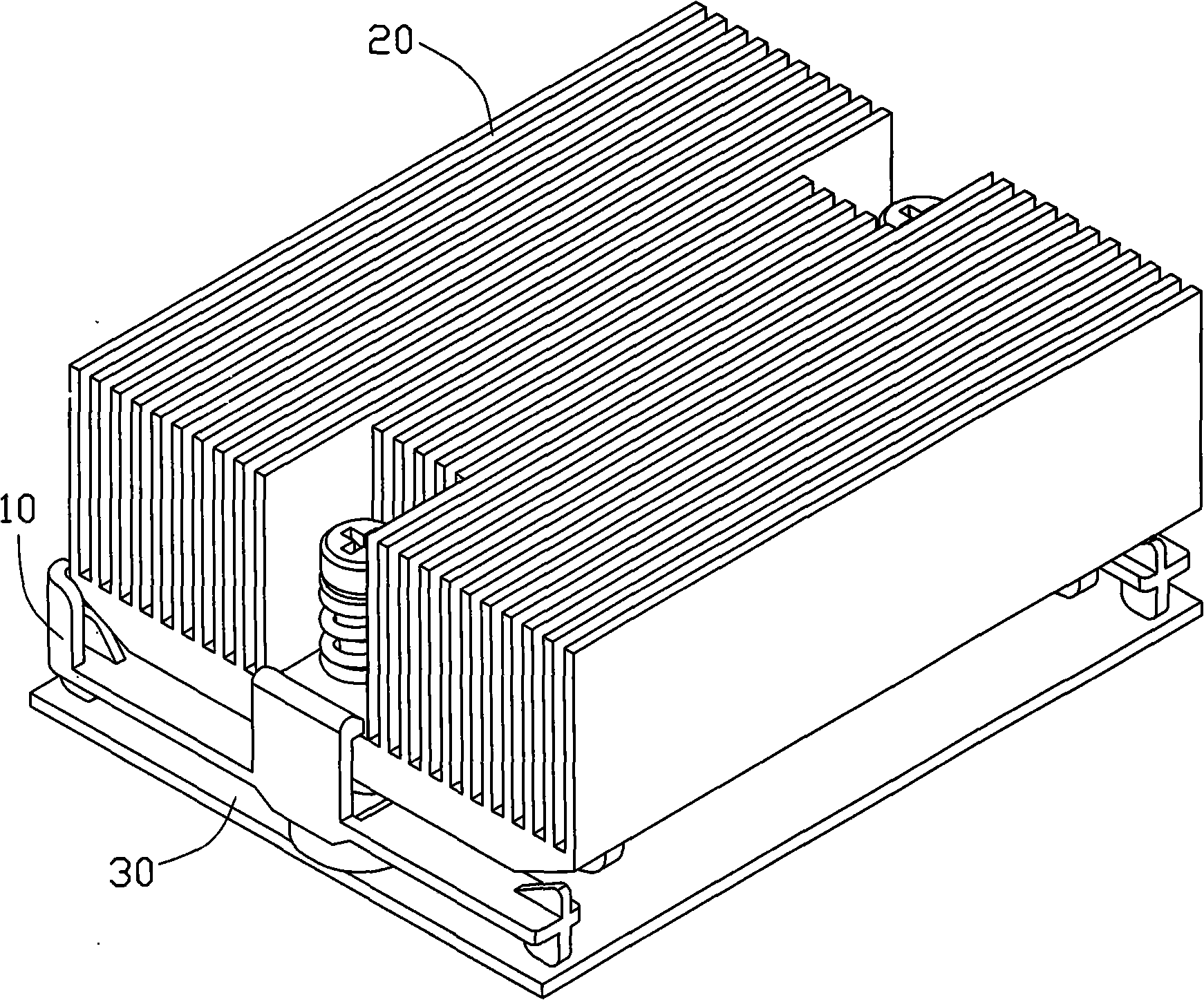

[0014] see figure 1 and figure 2 , the heat dissipation device of the present invention is used to dissipate heat to a heat-generating electronic component on the circuit board 30 such as a central processing unit 32, and it includes a heat sink 20 and a fixing module for fixing the heat sink 20 on the circuit board 30 10. The fixing module 10 can be pre-assembled with the heat sink 20 before being mounted on the circuit board 30 .

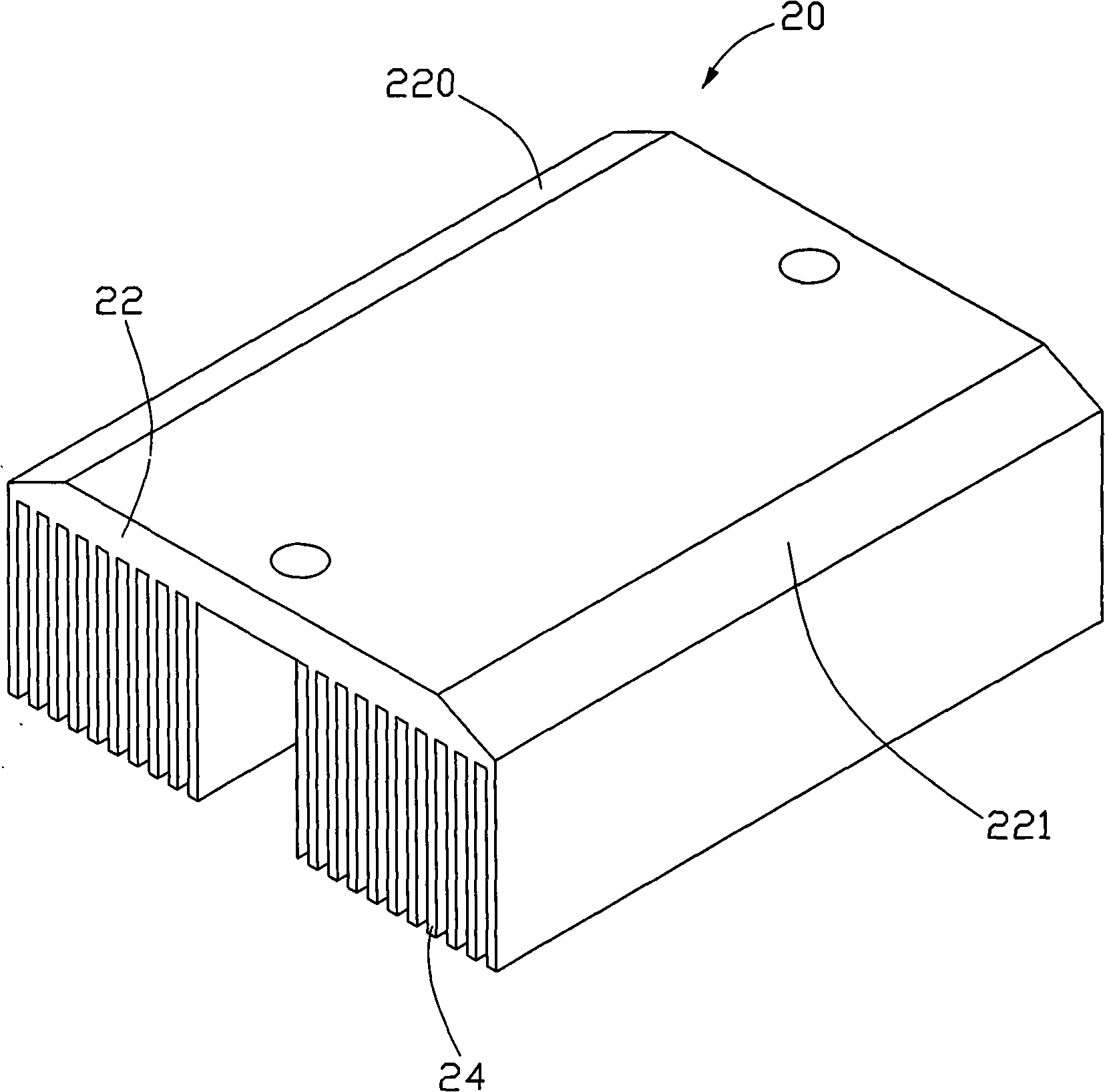

[0015] Also see image 3 The radiator 20 is an extruded aluminum radiator, including a base 22 and a plurality of cooling fins 24 extending vertically upward from the base 22 . Front and rear opposite ends of the base 22 are obliquely cut to form two slopes 220 , 221 , so as to facilitate the insertion of the radiator 20 into the fixed module 10 . In this embodiment, the slope 220 and the slope 221 are asymmetrical, wherein the angle between the slope 220 and the bottom plane of the base 22 is larger than the angle between the slope 221 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com