Start method and device for brushless dual-feedback electromotor

A double-fed motor and starting device technology, which is applied to the starter, electromechanical device, motor generator/starter of a single multi-phase induction motor, etc., can solve the complex structure of the brushless double-fed motor, motor overheating and torque oscillation , start-up and control difficulties, etc., to achieve the effects of small mechanical impact, improved reliability, and fewer times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

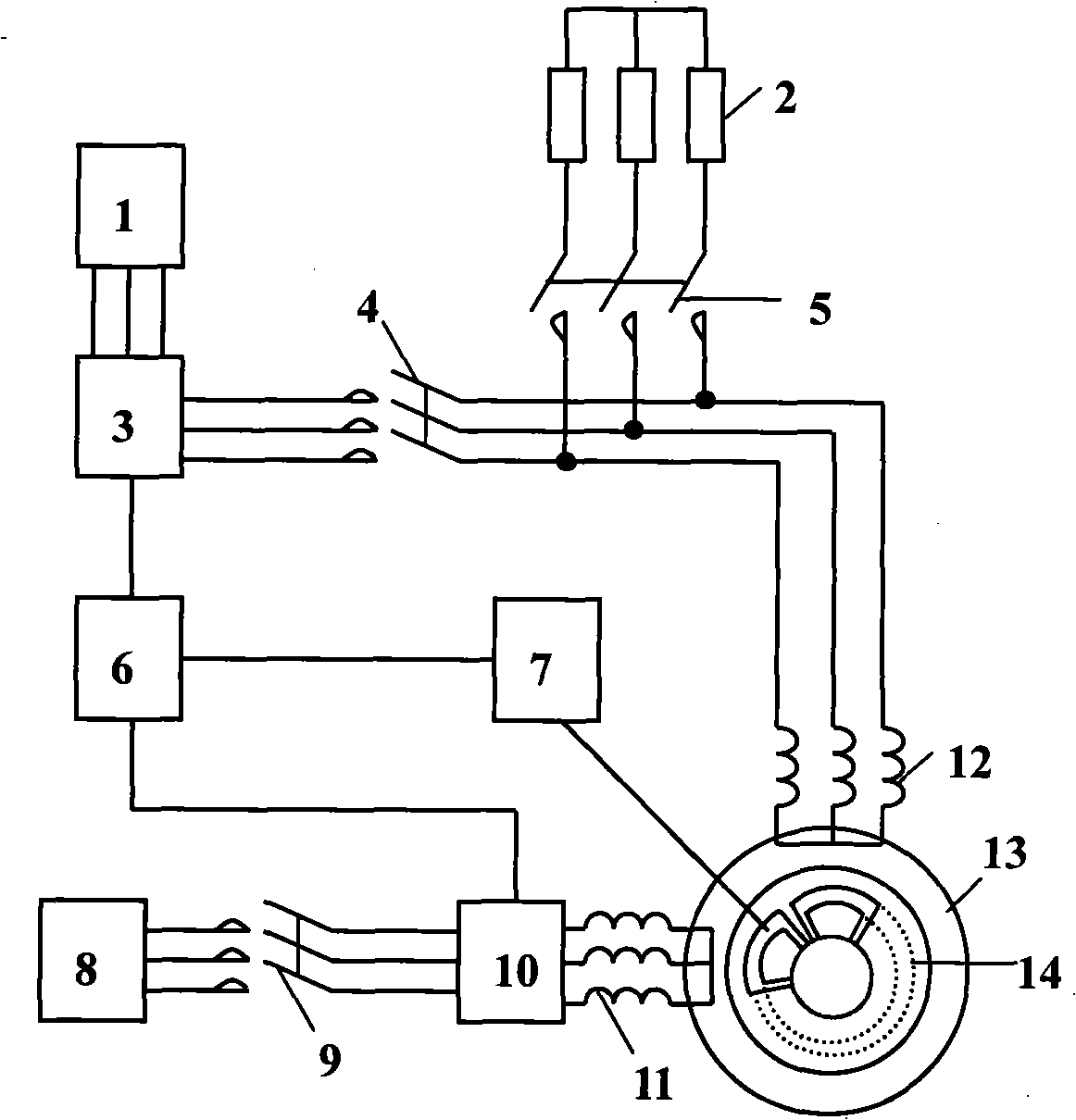

Embodiment 1

[0025] Embodiment 1. The number of pole pairs of the power winding Pp=3, the number of pole pairs of the control winding Pc=1, the power supply voltage of the power winding is 380V, the power supply voltage of the control winding inverter is 220V, the rated power is 2KW, and the asynchronous and stable speed at no load The given speed is 960 rpm, and the given speed is 810 rpm. The resistance value of each phase of the three-phase symmetrical starting resistor is 8 times that of the stator resistance of each phase of the control winding. The frequency conversion controller adopts a dual PWM voltage type inverter.

[0026] The specific startup method is as follows:

[0027] a. Before starting the brushless doubly-fed motor, keep the inverter switch 4 off, close the starting resistor switching switch 5, and connect the three-phase symmetrical starting resistor 2 into the control winding; and start working;

[0028] b. Close the power winding power switch 9, the power winding 11...

Embodiment 2

[0032] Embodiment 2: The resistance connected in series to the control winding is a three-phase symmetrical resistance, and the resistance value of each phase is 6 times of the stator resistance of each phase of the control winding. Others are the same as in Embodiment 1, omitted.

Embodiment 3

[0033] Embodiment 3. The resistors connected in series to the control winding are three-phase symmetrical resistors, and the resistance value of each phase is 10 times that of the stator resistance of each phase of the control winding. Others are the same as in Embodiment 1, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com