Liquid injection and humidity method for lithium ion battery

A lithium-ion battery and liquid injection technology, applied in secondary batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problems of increased wetting cost, high dew point temperature requirements of pressurized gas, etc., and achieve no increase in equipment. The effect of investment, battery internal resistance and capacity consistency improvement, and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

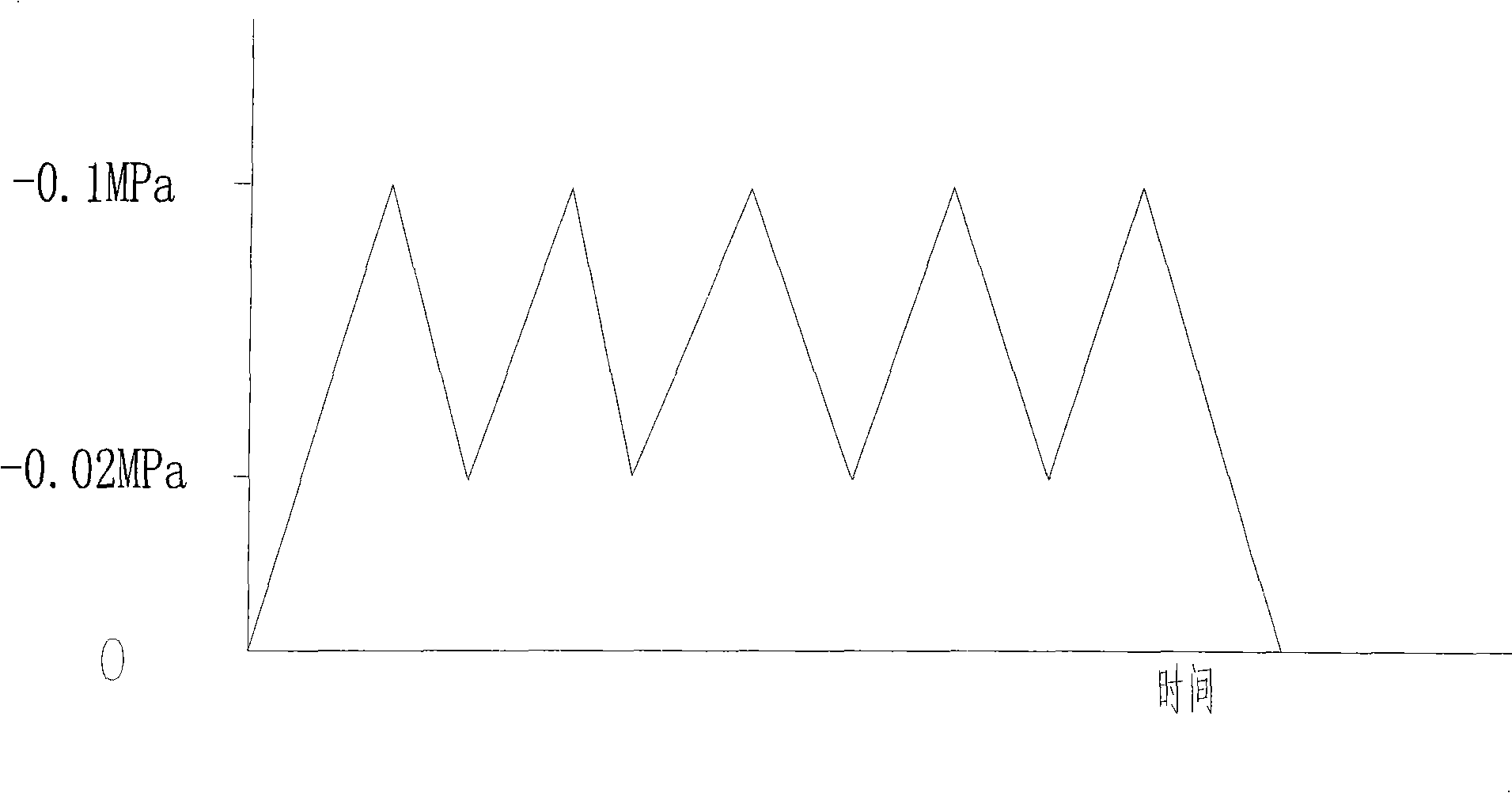

[0010] Example 1: A 2000 mAh battery in flexible packaging. After injecting liquid into the cell, put it into a sealed humidification box, vacuumize to -0.1Mpa, stop vacuuming, and make it drop to -0.02Mpa, and then vacuumize to -0.02Mpa again. -0.1Mpa, so uninterrupted and repeated wetting for 12 minutes.

Embodiment 2

[0011] Example 2: 2000 mAh battery with steel shell, put the cell in a sealed humidification box, evacuate to -0.1Mpa, after injecting liquid, make it drop to -0.02Mpa, and then evacuate to -0.1Mpa again, So uninterrupted repeated wetting for 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com