Technique for preparing food from cumquat fruit slag

A technology of dietary fiber and kumquat fruit, which is applied in the field of food processing, can solve the problems of high loss of water-soluble fiber, hemicellulose or cellulose, the inability to increase the value of dietary fiber, and low physiological activity of dietary fiber, and achieve optimal preparation process conditions parameter, effect of high dietary fiber value, high active ingredient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

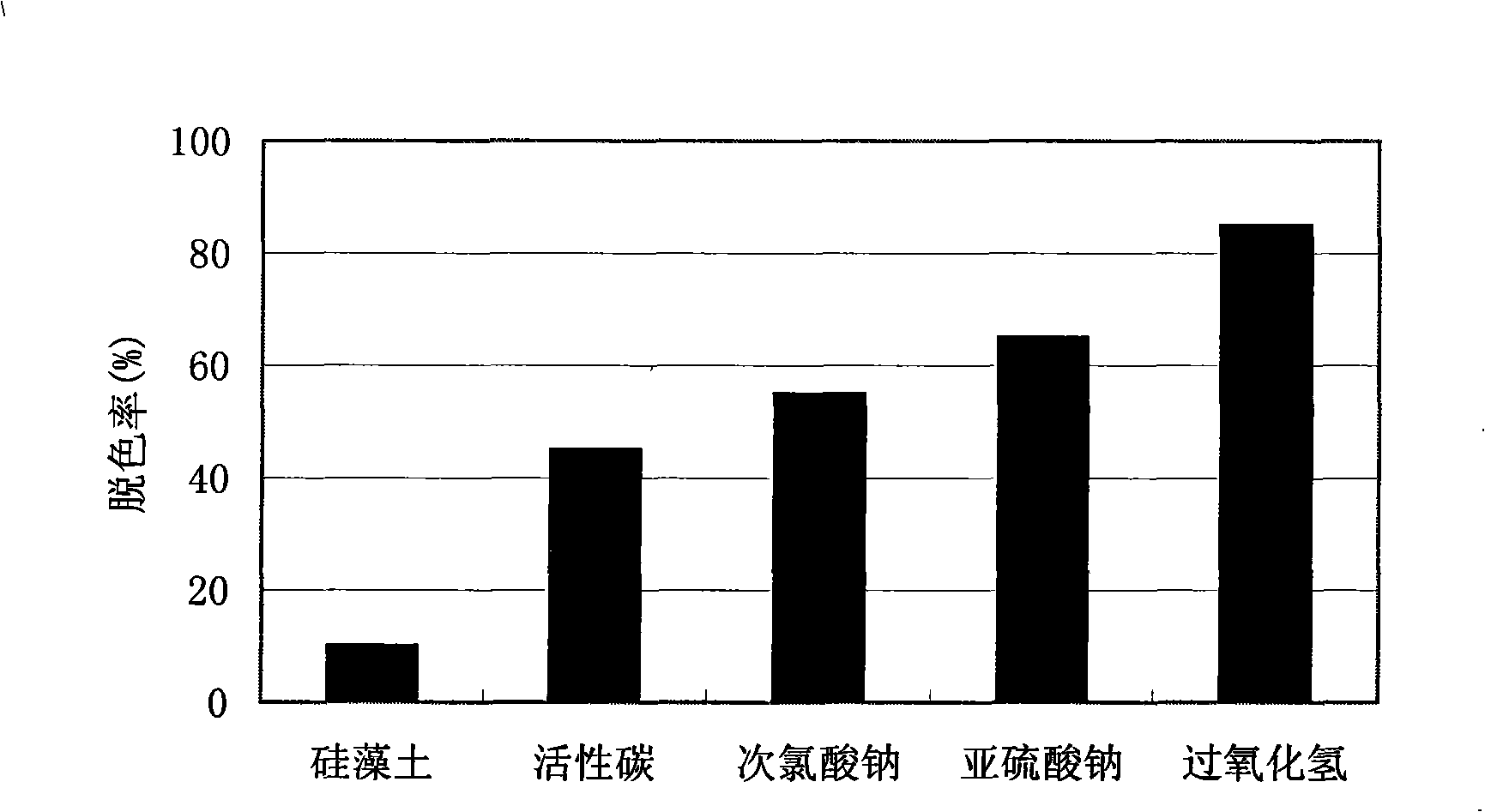

[0020] Using kumquat as raw material, after cleaning, drying and crushing, decolorization treatment: the decolorization treatment steps are: use H 2 o 2 As a decolorizing agent, according to the raw material and H 2 o 2 The weight ratio of 1: 10 is mixed for decolorization treatment, and the process condition of the decolorization treatment is: H 2 o 2 The addition amount is 4%, the pH value is 8, the time is 50min, the temperature is 20°C, and the stirring speed is 55r / min.

[0021] Acid treatment: hydrochloric acid with a weight concentration of 10% is used as the hydrolysis acid, and the acid treatment is carried out according to the weight ratio of raw materials and hydrochloric acid of 1:10. The process conditions of the acid treatment are: pH value 1, temperature 40°C, time 50min, Stirring speed 55r / min.

[0022] Filtrate after acid treatment, and the filtered filter residue is subjected to alkali treatment: NaOH aqueous solution is used to carry out alkaline hydrol...

Embodiment 2

[0026] With kumquat pomace as raw material, decolorization treatment after cleaning, drying and crushing: the decolorization treatment steps are: use H 2 o 2 As a decolorizing agent, according to the pomace raw material and H 2 o 2 The weight ratio of 1: 10 is mixed for decolorization treatment, and the process condition of the decolorization treatment is: H 2 o 2 The addition amount is 7%, the pH value is 11, the time is 80min, the temperature is 70°C, and the stirring speed is 60r / min.

[0027] Acid treatment: using hydrochloric acid with a weight concentration of 10% as the hydrolysis acid, acid treatment is carried out according to the weight ratio of pomace raw material and hydrochloric acid 1:10, the process conditions of the acid treatment are: pH value 2.5, temperature 90 ° C, time 90min, stirring speed 60r / min.

[0028] Filtrate after acid treatment, and the filtered filter residue is subjected to alkali treatment: NaOH aqueous solution is used to carry out alkal...

Embodiment 3

[0032] Use kumquat or kumquat pomace as raw material, after cleaning, drying, crushing and decolorization treatment: the decolorization treatment steps are: use H 2 o 2 As a decolorizing agent, according to the pomace raw material and H 2 o 2 The weight ratio of 1: 10 is mixed for decolorization treatment, and the process condition of the decolorization treatment is: H 2 o 2 The addition amount is 6%, the pH value is 10, the time is 70min, the temperature is 40°C, and the stirring speed is 55r / mm.

[0033]Acid treatment: use hydrochloric acid with a weight concentration of 10% as the hydrolysis acid, and mix the pomace raw material with hydrochloric acid at a weight ratio of 1:10 for acid treatment. The process conditions for the acid treatment are: pH value 1.5, temperature 60°C, time 60min, stirring speed 55r / min.

[0034] Filtrate after acid treatment, and the filtered filter residue is subjected to alkali treatment: NaOH aqueous solution is used to carry out alkaline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com