Steel tube concrete diagonal frame column spatial tubular joint and its manufacture method

A technology of steel pipe concrete and intersecting joints, which is applied in the direction of architecture and building construction, and can solve problems such as complex structures, no joint structure and calculation theory, and unclear force transmission, so as to achieve high bearing capacity and reduce welding work Clear effect of volume and power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below with reference to the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto.

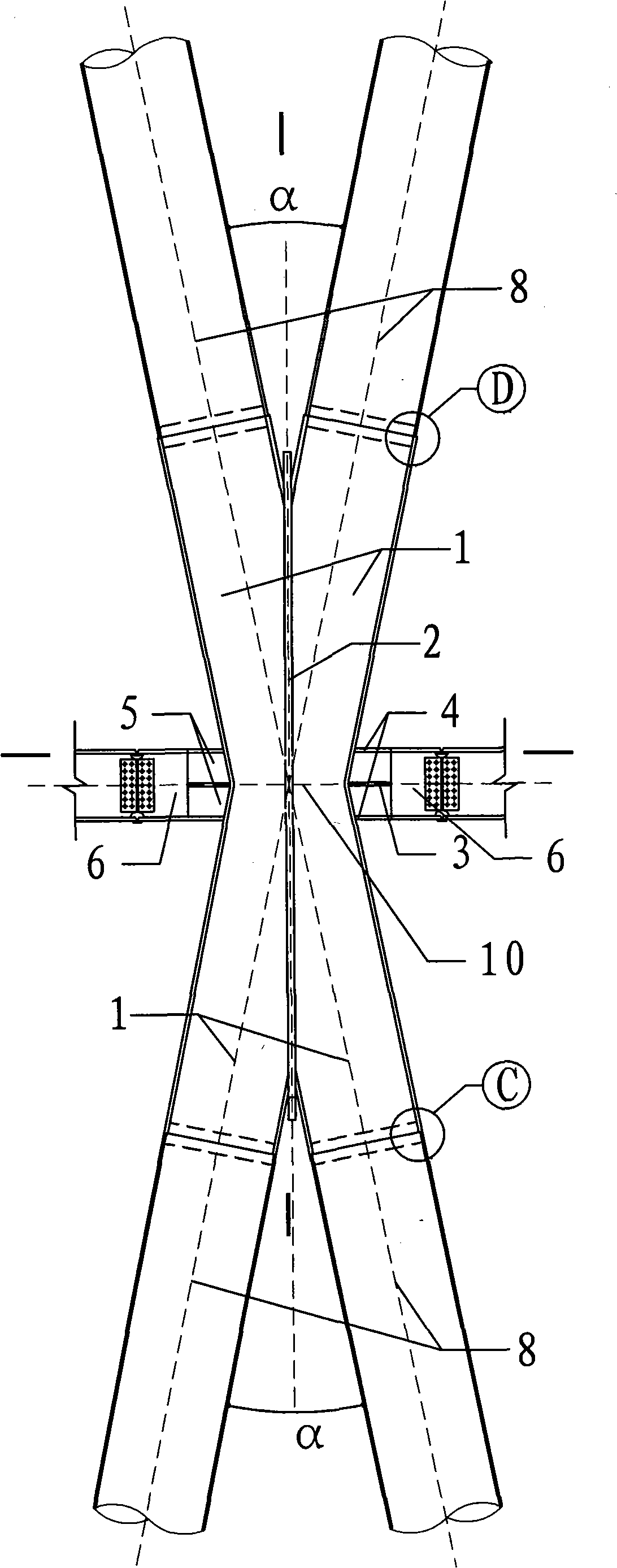

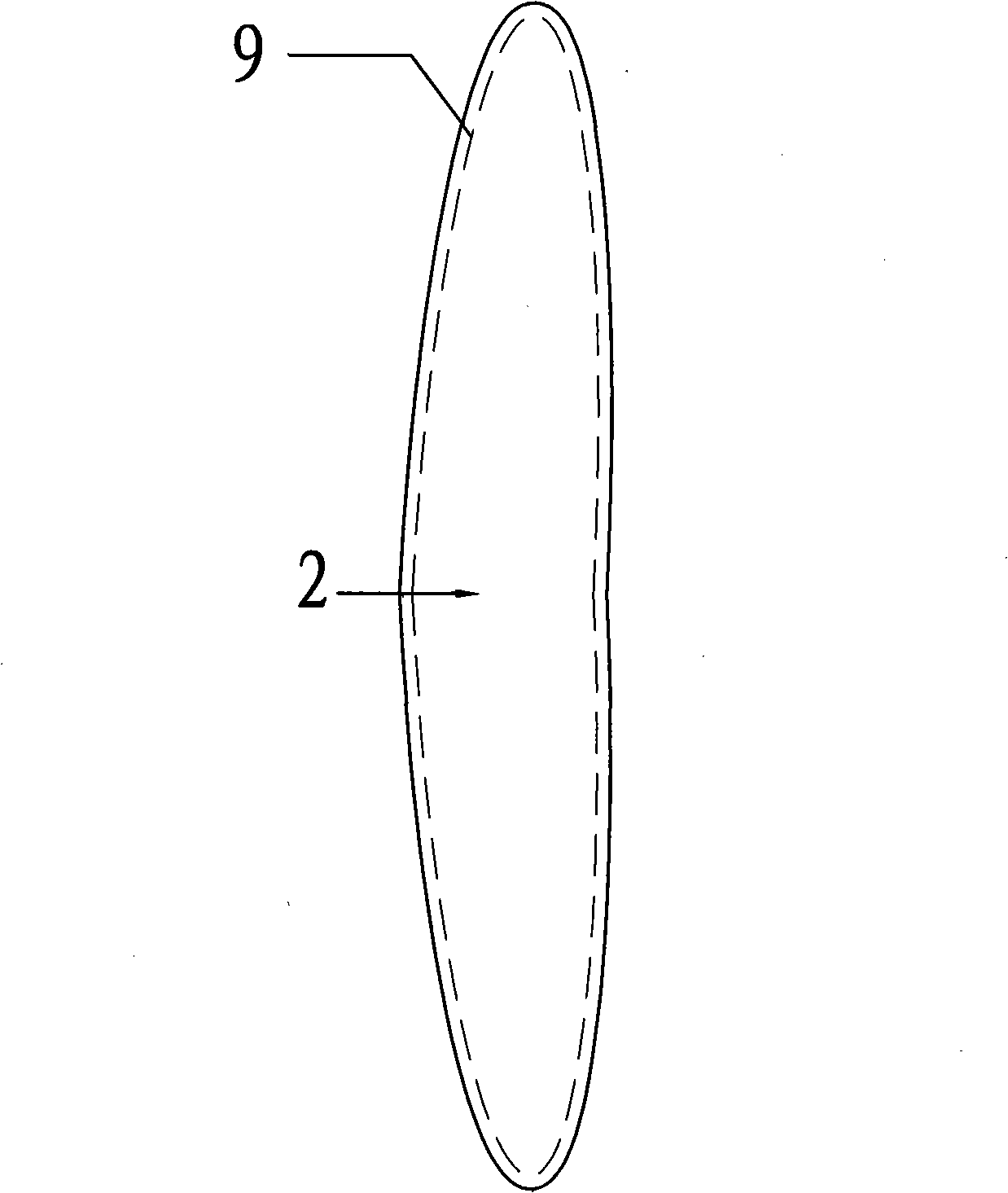

[0026] like Figure 1a , Figure 1b As shown, the intersecting joints of the oblique grid columns of the steel pipe concrete include: 1 round steel pipe, 2 elliptical connecting plates, 3 ring reinforcement plates, 4 ring plates, 5 stiffening ribs, 6 joints extending corbels. 4 The round steel pipes 1 intersect at the oval connecting plate, and the four round steel pipes 1 and the round steel pipes 1 and the oval connecting plate 2 are welded together; a round steel pipe welding seam 10 is formed on the central plane where the four round steel pipes 1 intersect, The hoop reinforcement plate 3 is composed of a pair of semi-annular steel plates (or multiple annular steel plates), which are welded on four round steel pipes at the center weld 10 of the intersecting node of the concre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com