Technique and device for removing dust of coke oven by boiler system

A smoke and dust removal technology, applied in coking ovens, smoke and dust removal, petroleum industry, etc., can solve the problems of furnace body deformation, inability to discharge raw gas, capture and dispose of smoke and dust, and high operating costs, so as to reduce size and weight , Good smoke and dust removal effect, high smoke and dust collection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

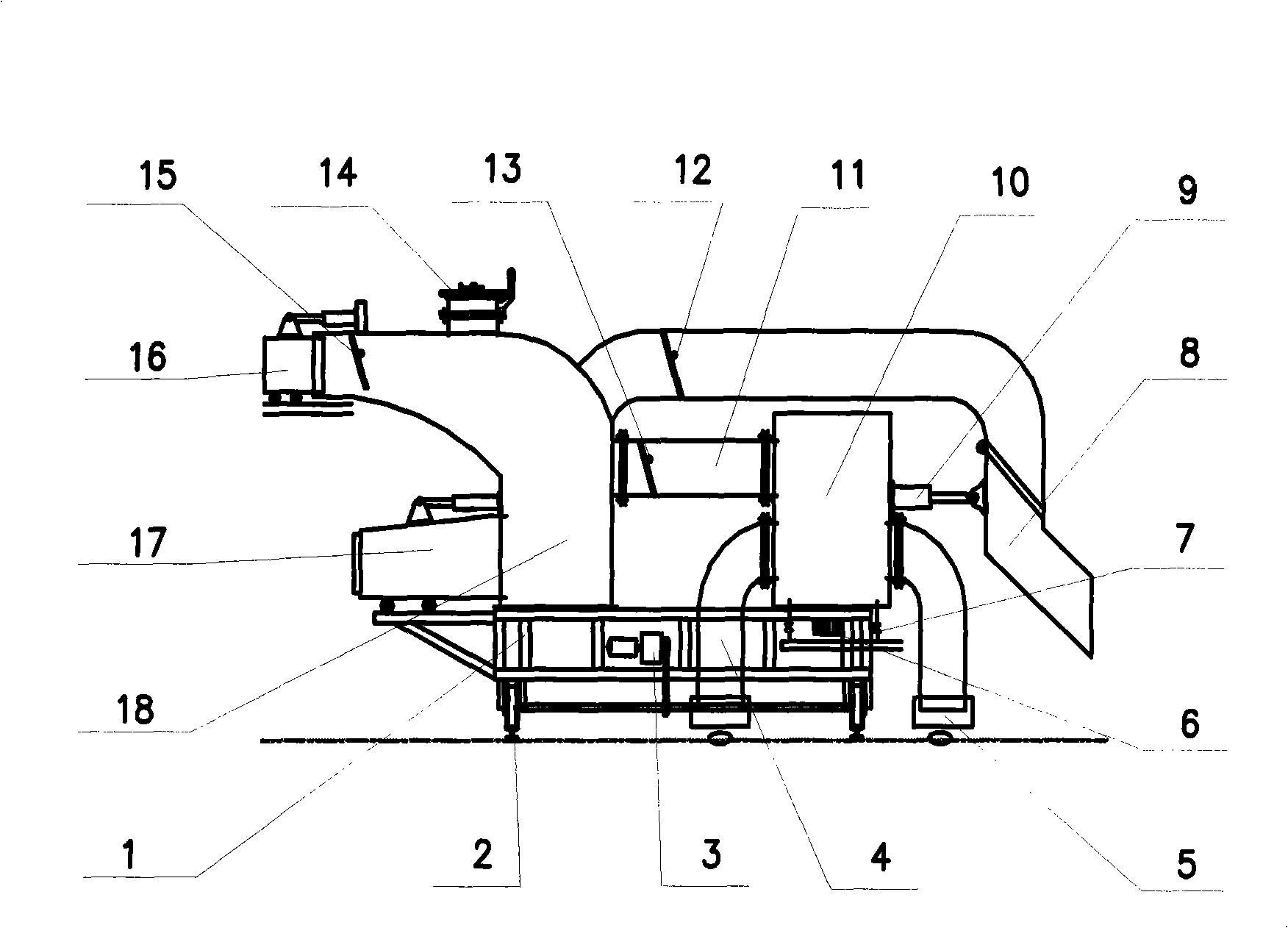

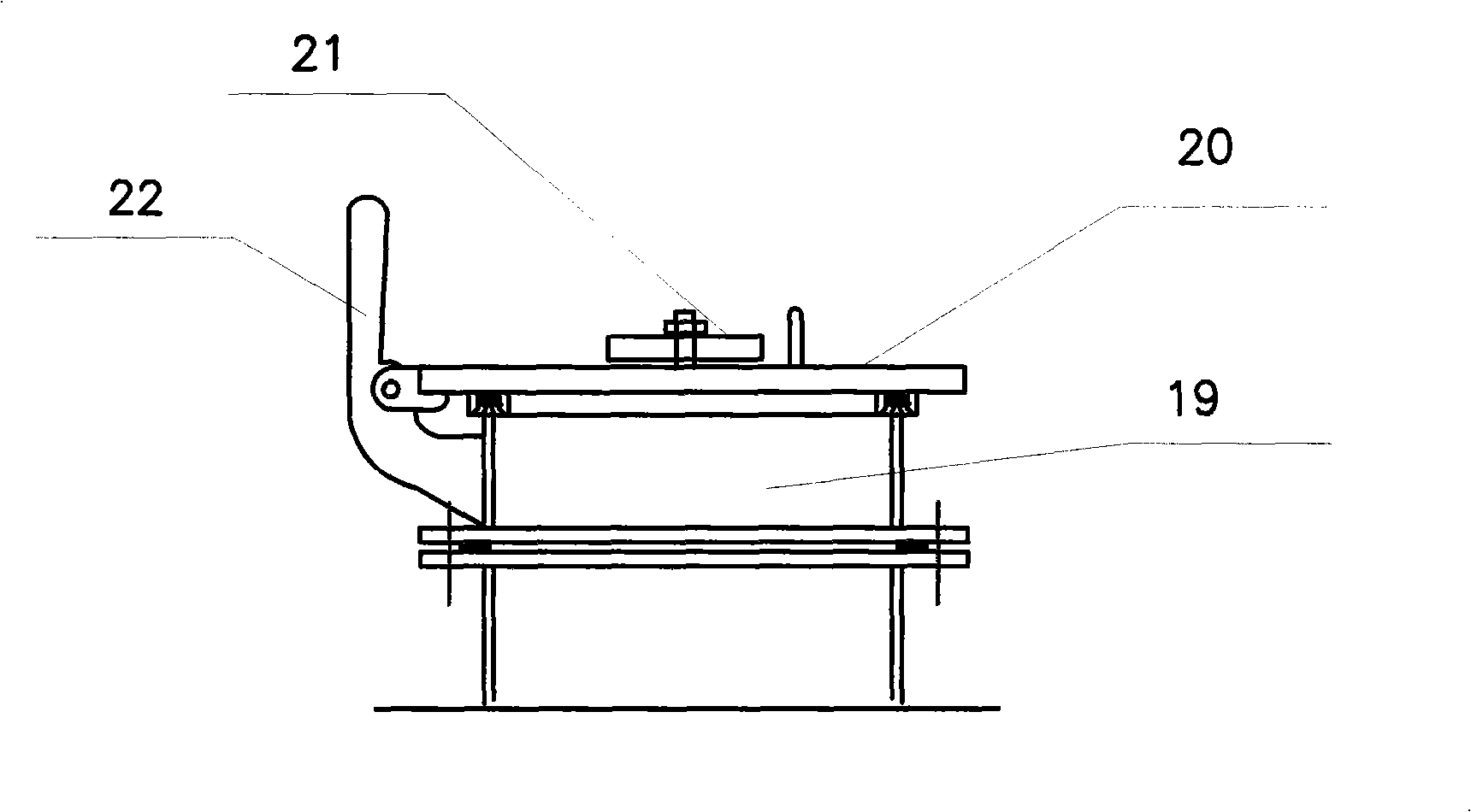

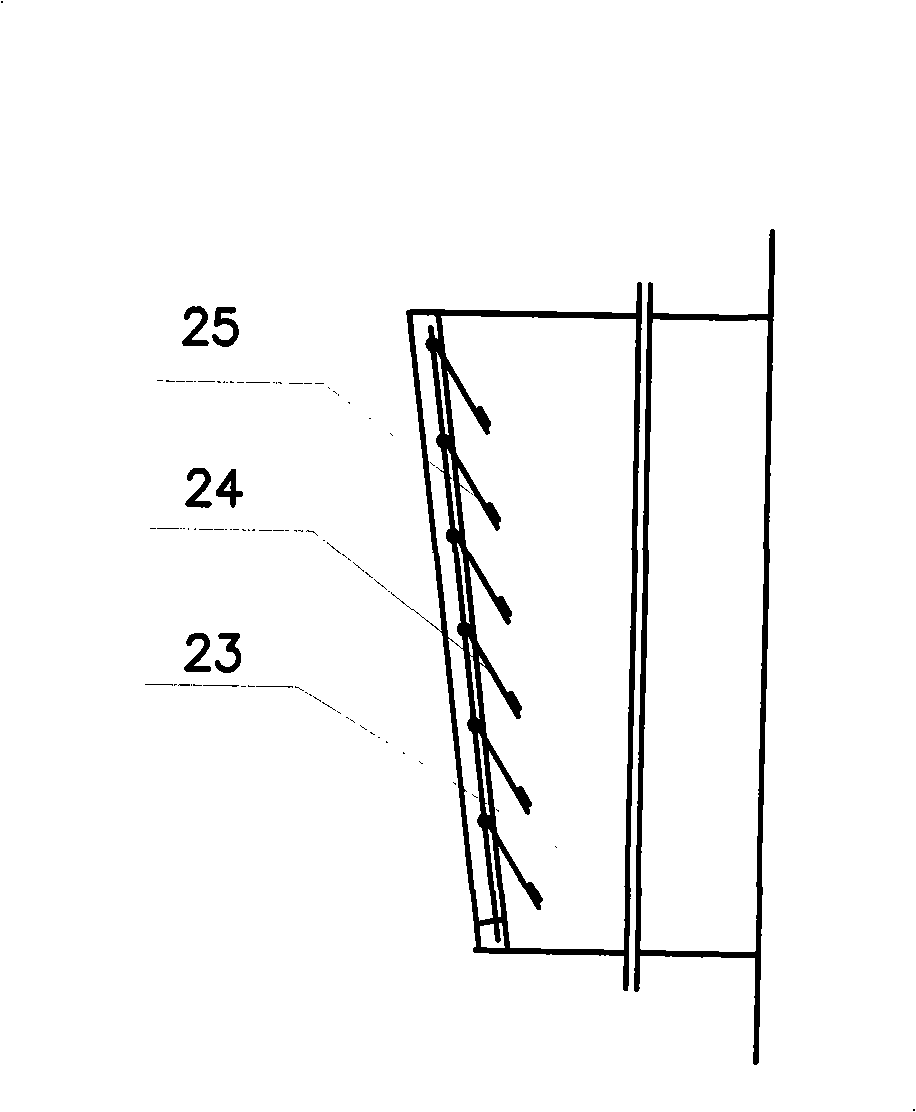

[0060] The body bracket 1 of the furnace top smoke and dust collection vehicle is equipped with a traveling steel wheel 2 and a motor 3. A combustion chamber 10 and a mixer 18 are installed on the bracket 1. There is a furnace mouth suction pipe 4 on both sides of the lower part of the combustion chamber 10, and a furnace mouth suction pipe 4 There is a telescopic sleeve 5 at the lower end of the furnace mouth, and a gas automatic ignition nozzle 7 and an adjustable damper 6 are installed at the lower end of the combustion chamber 10. There is a combustion exhaust gas outlet pipe 11 on the upper side of the combustion chamber 10, which communicates with the mixer 18, and the combustion exhaust gas outlet pipe 11 is equipped with an automatic turning plate 13 for the combustion chamber; the upper part of the mixer 18 has a telescopic sleeve 16 for the coke-stopping car and a sleeve 8 for collecting and distributing air at the furnace door on the side of the machine. plate 15. T...

Embodiment 2

[0066] During the coking process, the intermittent smoke and dust generated above the furnace door frame are gathered in the dust collection hood of the coke pick-up truck under the action of thermal buoyancy and the suction of the fan, and the mixing temperature of the smoke and air is 170°C.

[0067] During the coal charging process, the 650°C high-temperature combustible waste gas from the coke oven carbonization chamber enters the combustion chamber, and the air volume is adjusted to control the temperature of the combustion chamber to 875°C to completely burn the combustible waste gas, and the exhaust gas after combustion is collected from the coke oven door. The flue gas and distribution air enter the mixer for mixing, and the temperature of the mixed flue gas is 220°C.

[0068] After the dust gas in the gas-collecting pipeline is separated by the cyclone separator, it enters the boiler through the blower, and is fully burned under the conditions of a temperature of 1025 ...

Embodiment 3

[0070] During the process of coking, the fumes generated intermittently and above the furnace door frame are collected in the coke evacuation hood under the action of thermal buoyancy and the suction of the fan, and the mixing temperature of the dust and air is 180°C.

[0071] During the coal charging process, the 700°C high-temperature combustible waste gas from the coke oven carbonization chamber enters the combustion chamber, and the air volume is adjusted to control the temperature of the combustion chamber to 900°C to completely burn the combustible waste gas, and the exhaust gas after combustion is collected from the coke oven door. The flue gas and distribution air enter the mixer for mixing, and the temperature of the mixed flue gas is 230°C.

[0072] After the dust gas in the gas-collecting pipeline is separated by the cyclone separator, it enters the boiler through the blower, and is fully burned under the conditions of a temperature of 1050 ° C and an air excess coef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com