Environmental protection silent paper crusher

A paper shredder and silent technology, applied in mechanical equipment, shock absorbers, grain processing, etc., can solve problems such as unsatisfactory effects, achieve obvious noise reduction effects, scientific design, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

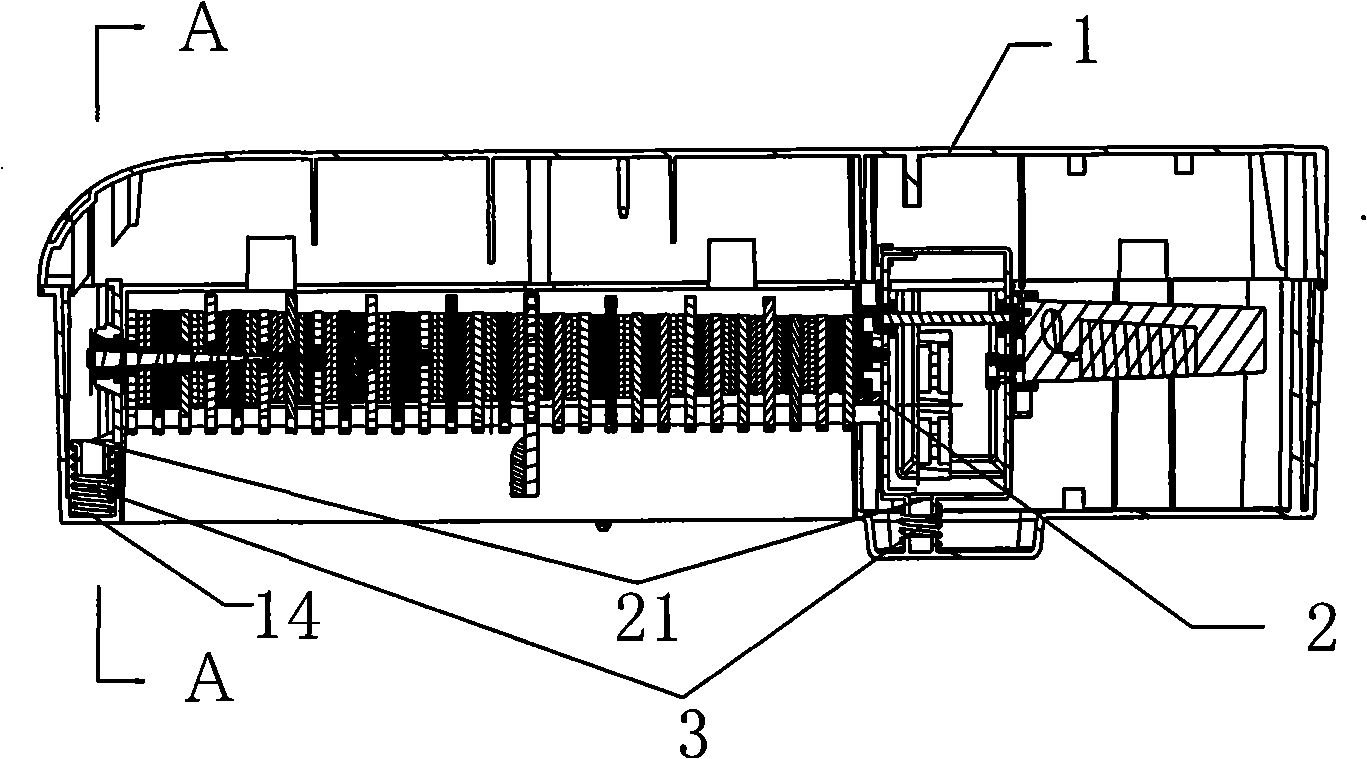

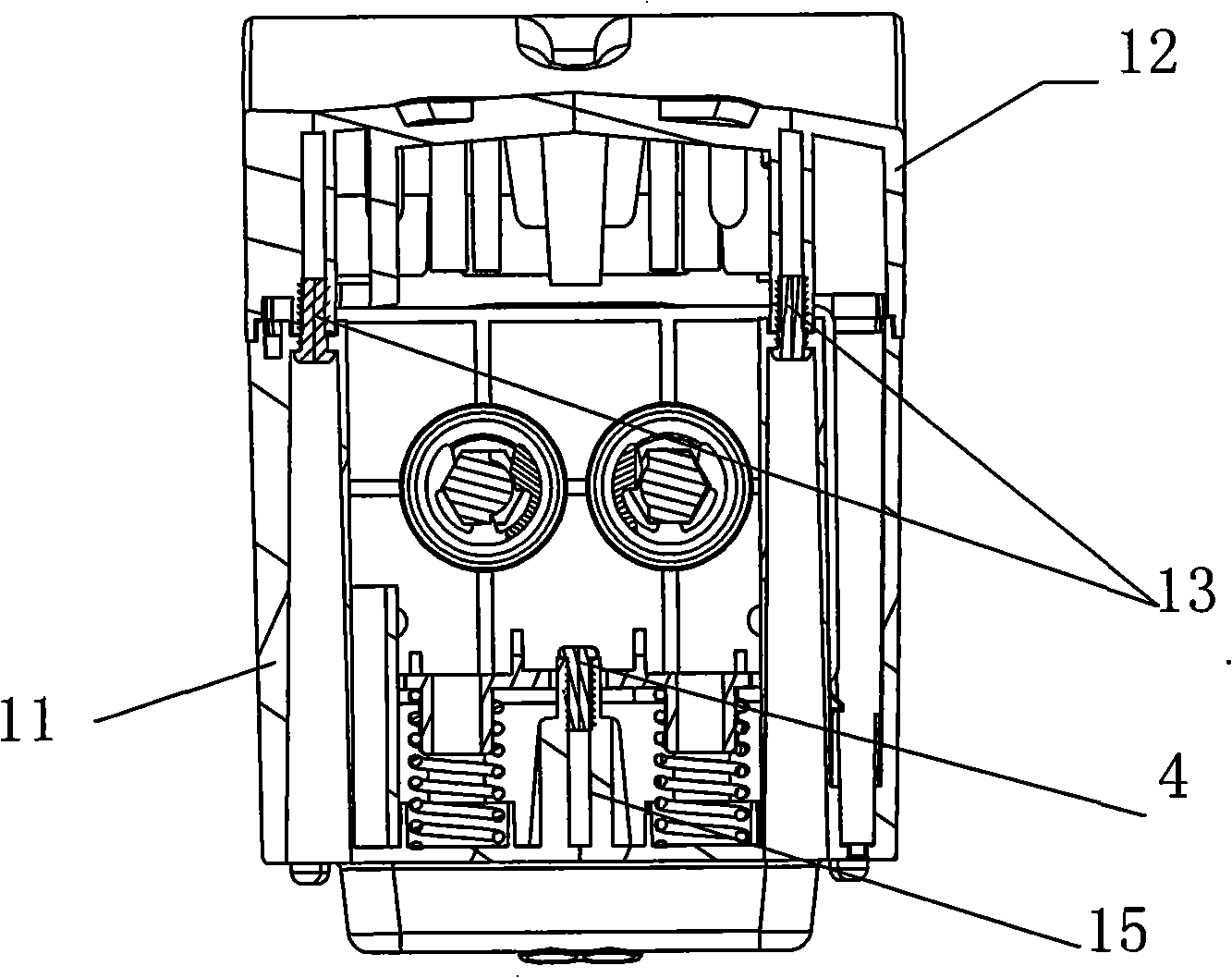

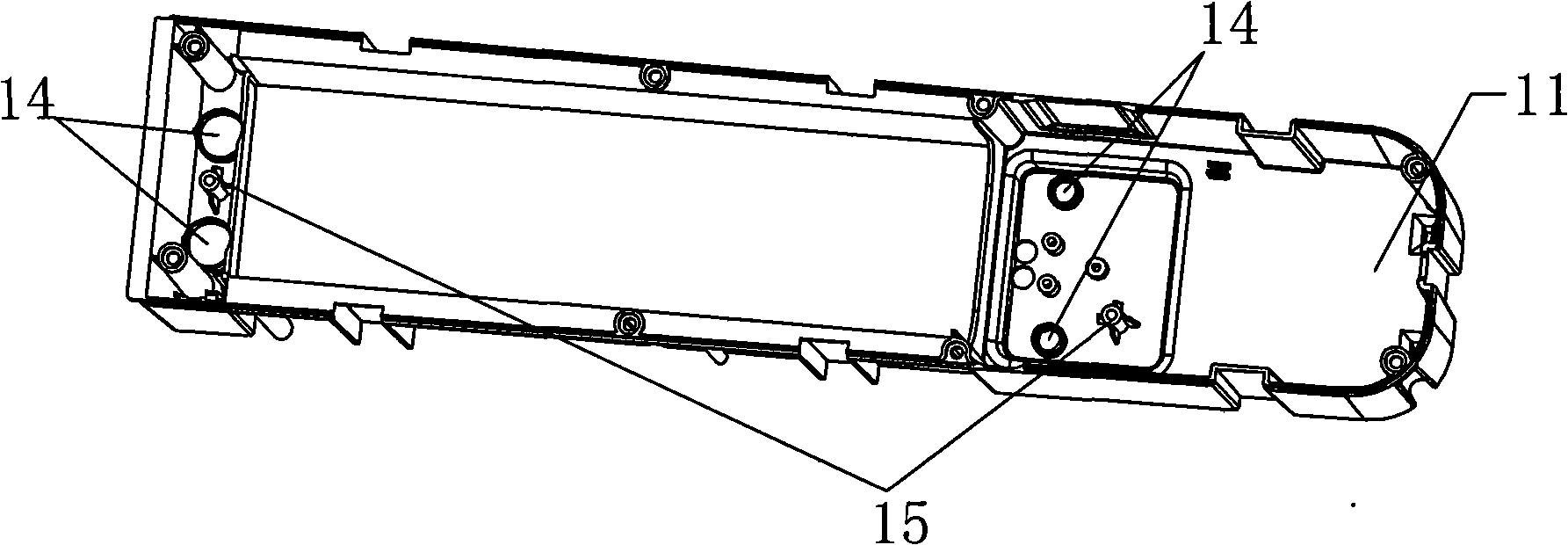

[0016] Example 1: from figure 1 and figure 2 It can be seen that the micro-noise shredder is composed of a casing 1 and a shredder core 2 arranged inside it. The casing 1 is composed of a lower bottom cover 11 and an upper cover 12 buckled thereon, and the upper cover 12 and the lower bottom cover 11 are fixedly connected by screws 13 . There is a space between the upper cover 12 and the top surface of the inner shredder core 2 . The four corners of the inner bottom surface of the lower bottom cover 11 are provided with pits 14 for embedding the spring 3 and screw holes 15 for fixing the shredder core 2 (see image 3 ). The four corners of the bottom of the shredder core 2 are provided with bosses 21 corresponding to the pits 14 on the bottom surface of the lower bottom cover 11 and capable of being introduced into the ends of the spring 3 .

[0017] The installation relationship between the shredder core 2 and the casing 1: After inserting the springs 3 in the pits 14 on...

Embodiment 2

[0018] Example 2: From Figure 4 It can be seen that this is another environment-friendly silent paper shredder, its structure is basically the same as that of Embodiment 1, the only difference is that the spring 3 in Embodiment 1 is replaced by an elastic plastic pad 6, which can be embedded in the concave bottom of the bottom cover 11. The elastic plastic pad 6 of the pit 14 is a ring structure, and its end is provided with a stepped hole 61 that can cooperate with the boss 21 on the bottom surface of the shredder core. Its use effect is the same as spring 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com