Negative oxygen ion gas-jetting flow-guiding top side type cooker hood

A technology of negative oxygen ions and range hoods, which is applied in the fields of oil fume removal, heating methods, household heating, etc., can solve problems such as energy consumption, and achieve the effects of reducing vibration, convenient cleaning, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

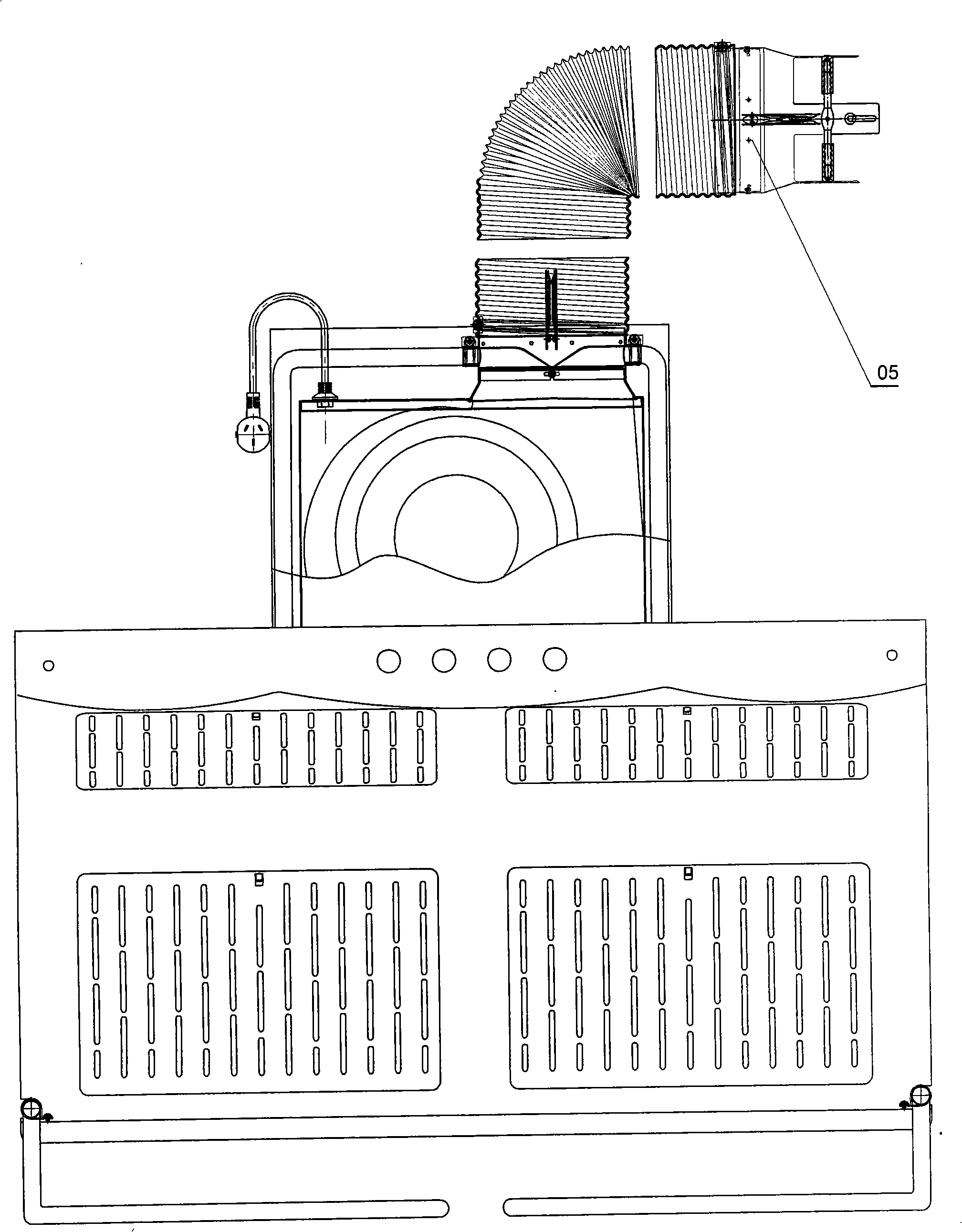

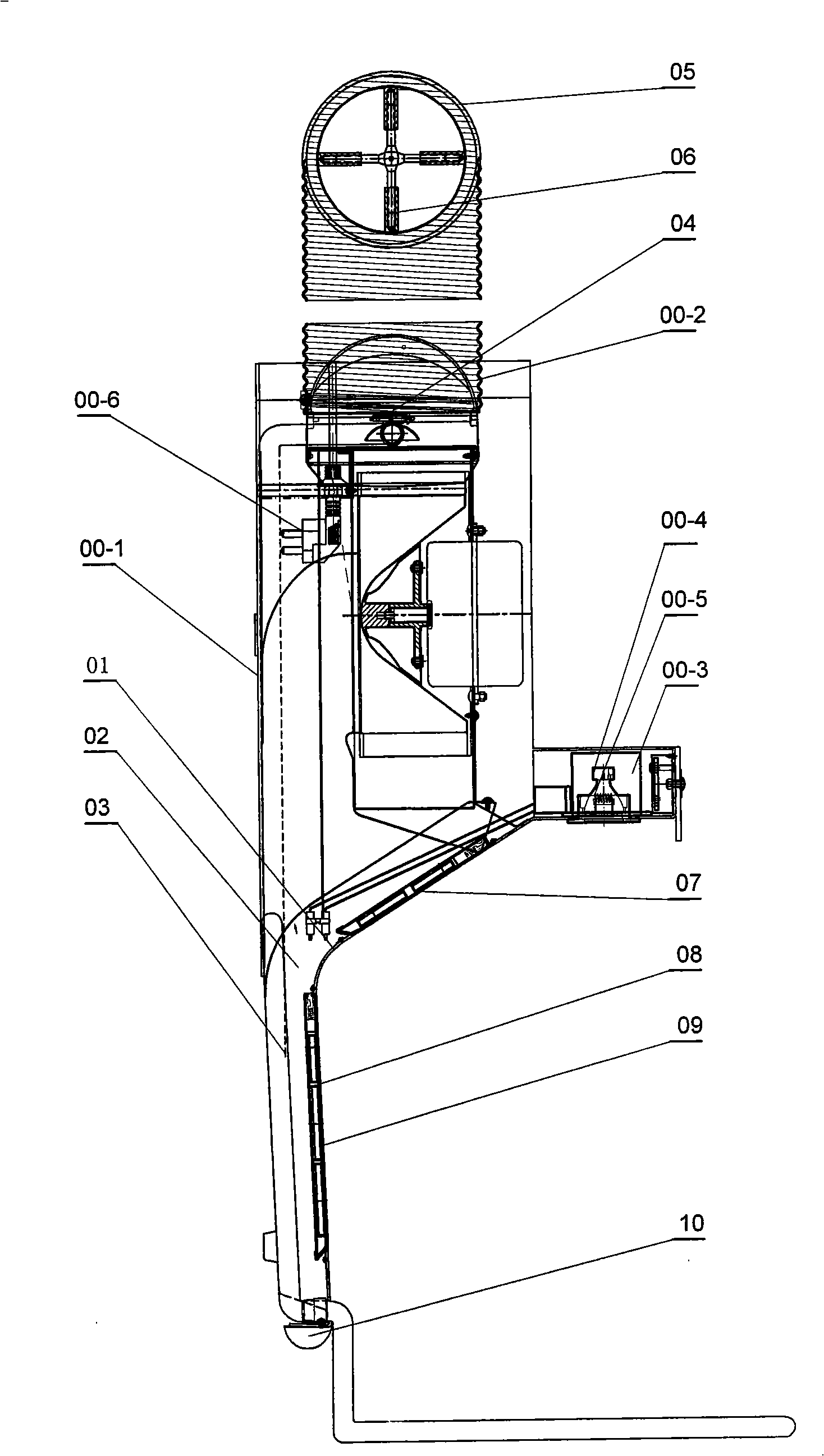

[0074] Such as Figures 24 to 26 As shown, the negative oxygen ion jet diversion of the present invention has an equal-thick inner chamber top-side range hood comprising: a panel, a smoke collecting hood, a rectifying air cylinder, a lower connecting cylinder, an upper connecting cylinder, a wall part, a lower Separator, upper separator, negative oxygen ion jet guide cover, oil cup, wall hook, corrugated smoke pipe, control switch, lighting lamp, negative oxygen ion generator, power cord, etc. The connection of each component is the same as in the embodiment, and the rear air intake is equal to the thickness of the negative oxygen ion top-side range hood.

Embodiment 2

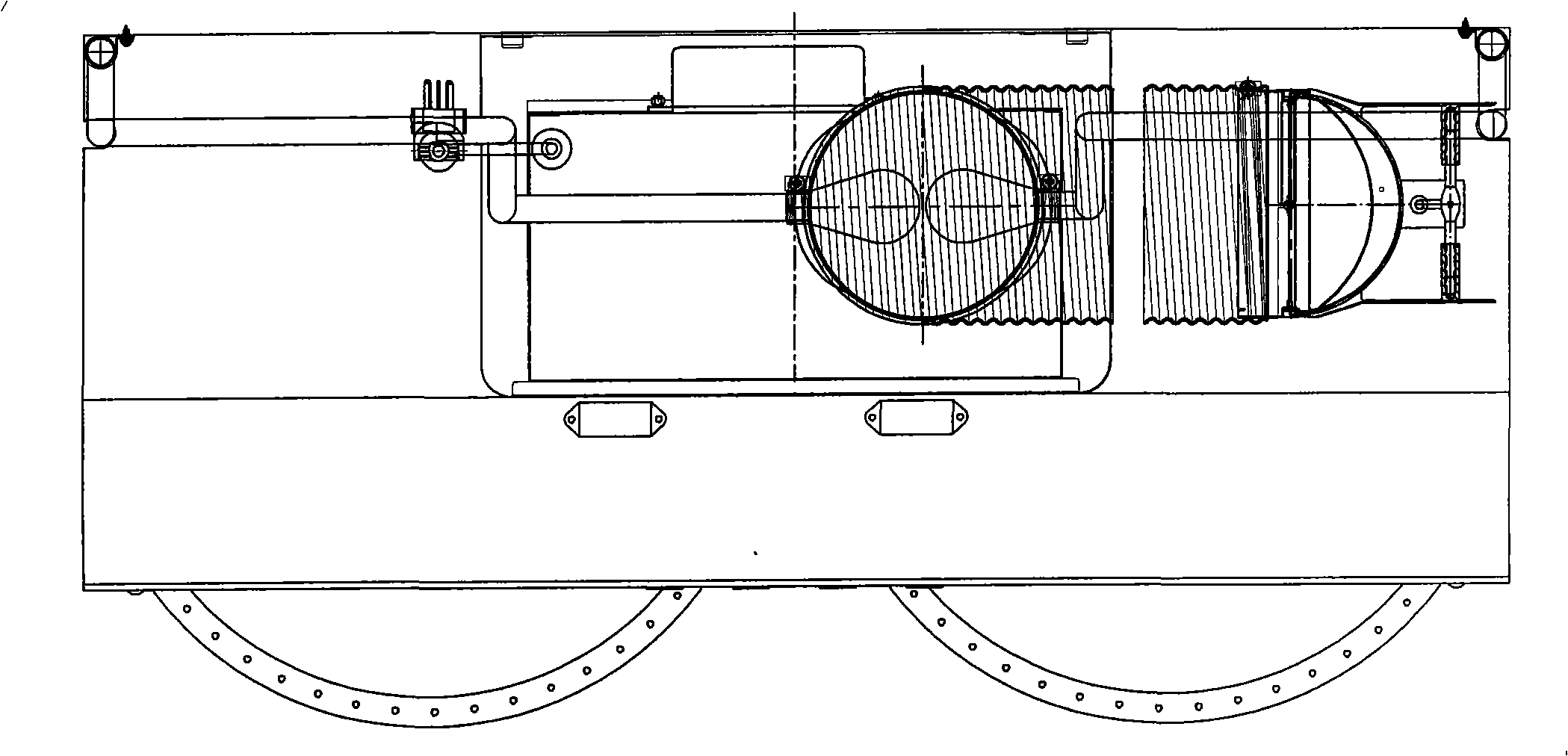

[0076] Such as Figures 27-29 As shown, the range hood of the present invention includes: a panel, a smoke collecting hood, a rectifying air cylinder, a lower connecting cylinder, an upper connecting cylinder, wall parts, a lower separator, an upper separator, a negative oxygen ion jet-type hood, Oil cups, wall hooks, corrugated smoke pipes, control switches, lights, negative oxygen ion generators, power cords, etc. The connection of each component is the same as in the embodiment, and the panel of the range hood adopts a curved shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com