Geotextile and method for manufacturing same

A technology of geotextiles and needle-punched non-woven fabrics, which is applied in the direction of non-woven fabrics, textiles, and papermaking. It can solve the problems that geotextiles cannot be explained by themselves, and achieve the effect of high quality, low impurity content, and large thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

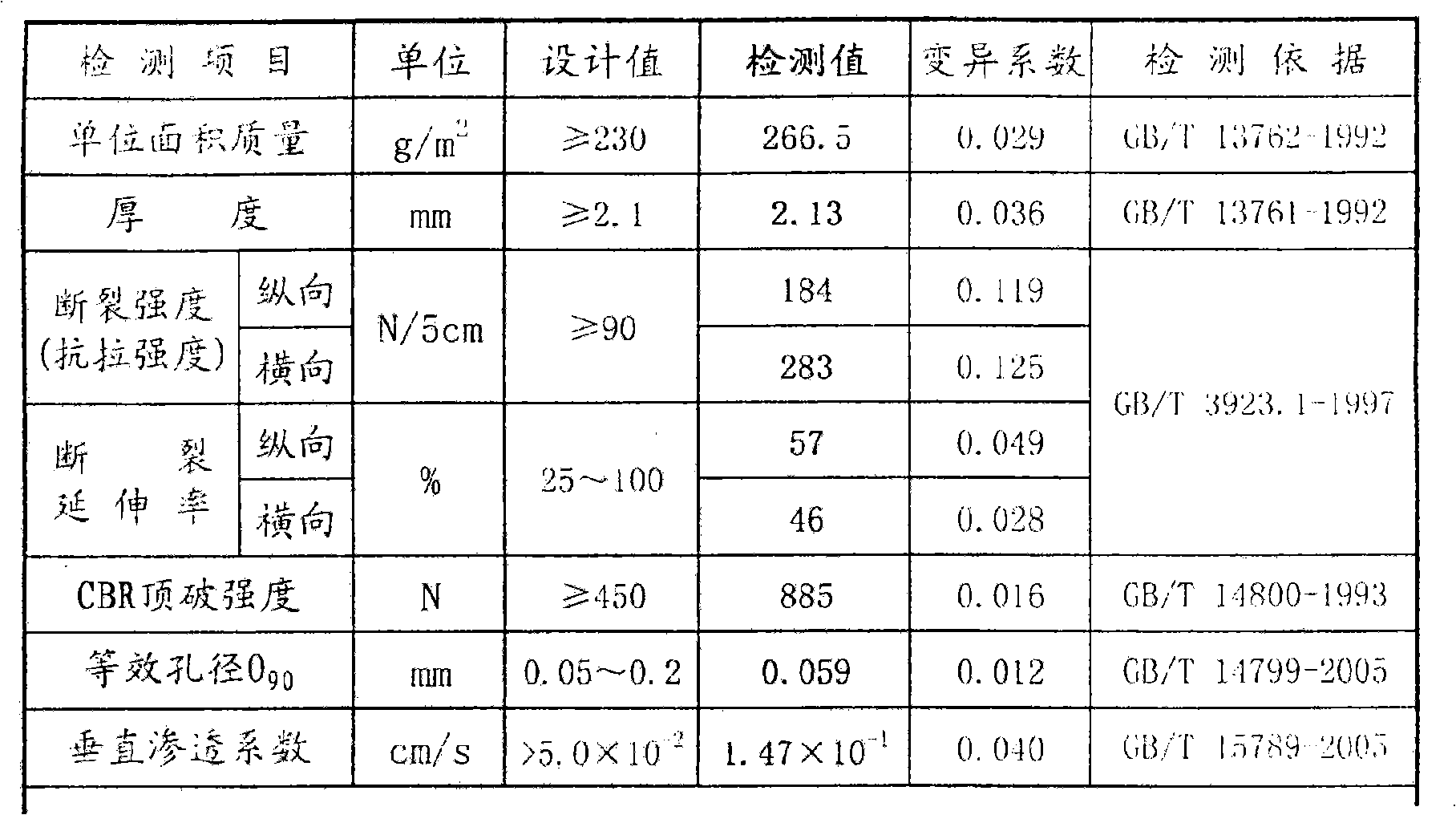

Embodiment 1

[0019] A geotextile made entirely of viscose fibers. Its manufacturing method comprises the following steps: opening, mixing, carding, web forming, web laying, needle punching, and roll forming; the above steps are carried out under normal humidity and normal temperature; The needling frequency is 450 times / min, the needling depth is 6.5mm, and the rolling speed is 2m / min; the second needling frequency is 550 times / min, the needling depth is 6.0mm, and the rolling speed is 2m / min ;The frequency of three acupuncture is 550 times / min, the depth of acupuncture is 3.5mm, and the speed of rolling is 2m / min.

Embodiment 2

[0021] A geotextile made entirely of viscose fibers. Its manufacturing method comprises the following steps: opening, mixing, carding, web forming, web laying, needle punching, and roll forming; the above steps are carried out under normal humidity and normal temperature; The needling frequency is 500 times / min, the needling depth is 7mm, and the rolling speed is 2.5 m / min; the second needling frequency is 600 times / min, the needling depth is 6.5 mm, and the rolling speed is 2.5 m / min; The three acupuncture frequency is 600 times / min, the acupuncture depth is 3.5mm, and the rolling speed is 2.5m / min.

Embodiment 3

[0023] A geotextile made entirely of viscose fibers. Its manufacturing method comprises the following steps: opening, mixing, carding, web forming, web laying, needle punching, and roll forming; the above steps are carried out under normal humidity and normal temperature; The needling frequency is 550 times / min, the needling depth is 7.5mm, and the rolling speed is 3m / min; the second needling frequency is 650 times / min, the needling depth is 7.0mm, and the rolling speed is 3m / min ; The frequency of three acupuncture sessions is 650 times / min, the depth of acupuncture is 4mm, and the speed of rolling is 3 m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com