Reboiler cleaning agent and cleaning method thereof

A technology of reboiler and cleaning agent, applied in the field of cleaning agent, can solve the problems of reboiler cleaning problem, difficult cleaning and descaling work, and high cleaning frequency, so that the descaling process is simple but not complicated, and it is economical. and environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

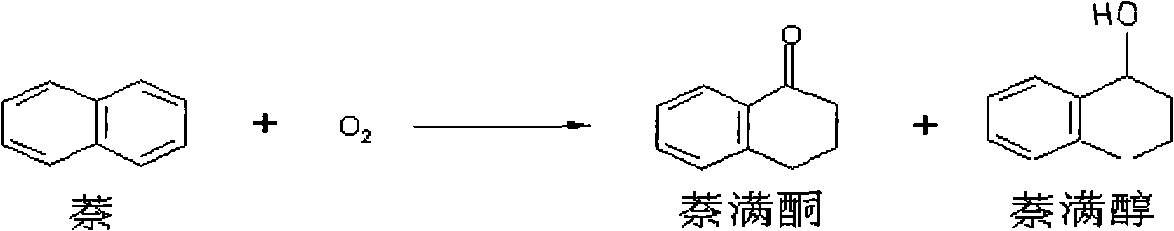

Embodiment 1

[0025] First, drain all the heat transfer oil in the reboiler 9, then close the heat transfer oil entering the reboiler pipeline valve 7 and the reboiler heat transfer oil outlet pipeline valve 2, and simultaneously open the cleaning agent to enter the reboiler pipeline valve 6 and clean The agent enters the cleaning agent storage tank inlet pipeline valve 3; fills in the cleaning agent storage tank 4 by the following raw materials in parts by weight: 5 parts of α-methylnaphthalene, 52 parts of β-methylnaphthalene, 15 parts of naphthalene and from The reboiler cleaning agent purchased in the market from 28 parts of heavy aromatic solvents with a distillation range of 190-270°C provided by Wujiang Hongwei Environmental Protection Auxiliary Co., Ltd., Wujiang City, Jiangsu Province, China, and then start conveying and reboil Pipeline pump 5 for cleaner cleaning agent, the control flow rate is 30m 3 / h, the reboiler cleaning agent is introduced into the reboiler 9 through the reb...

Embodiment 2

[0027] Only change the selected α-methylnaphthalene to 8 parts, β-methylnaphthalene to 58 parts, naphthalene to 2 parts, heavy aromatic hydrocarbon solvent to 32 parts, and change to Pingling, Liyang City, Jiangsu Province, China Liyang Chengxing Chemical Co., Ltd., No. 38 East Road, provided heavy aromatic solvents with a distillation range of 200-245°C, and the circulation flow rate of the cleaning agent was changed to 35m 3 / h, the temperature of the cleaning agent cycle cleaning is changed to 100°C, and the cycle cleaning time is changed to 8.5h. All the other are with embodiment 1.

Embodiment 3

[0029] Only change the selected α-methylnaphthalene to 10 parts, β-methylnaphthalene to 65 parts, naphthalene to 6 parts, heavy aromatic solvent to 19 parts, and the cleaning agent circulation flow to 25m 3 / h, the temperature of cleaning agent circulation cleaning is changed into 85 ℃, and the time of circulation cleaning is changed into 15h, after cleaning, the reboiler cleaning agent containing organic dirt discharged from reboiler 9 is used as fuel, and all the other same Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com