Improved blue algae treatment utilization method

A technology of cyanobacteria and livestock and poultry manure, which is applied to the treatment and application of biological organic parts, the preparation of organic fertilizers, etc., can solve the problems that are not necessarily scientific, and the digestion rules are not clear, so as to facilitate the expansion of production and save the cost of treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

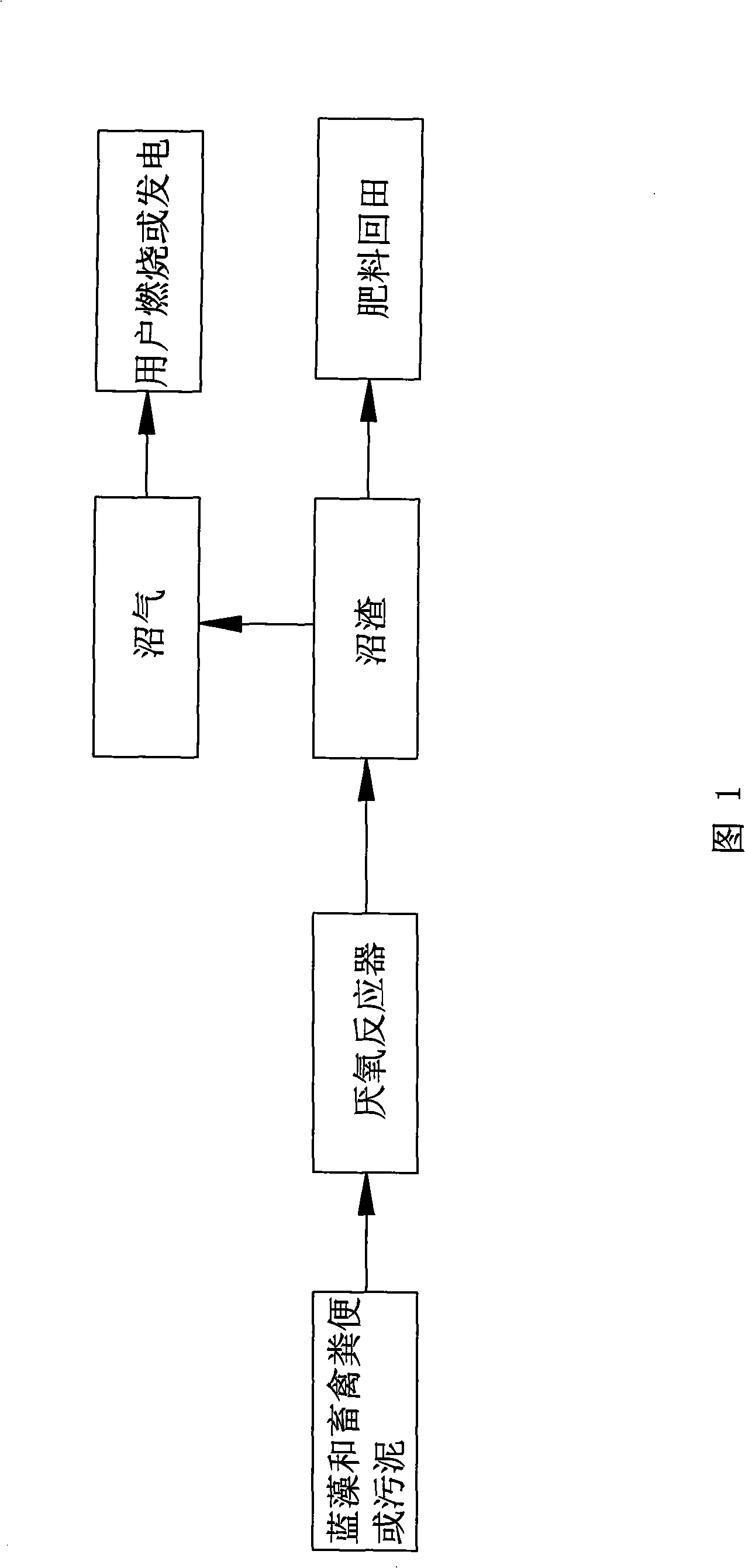

Image

Examples

Embodiment 1

[0018] Embodiment 1, blue-green algae and poultry excrement are mixed in anaerobic reactor by dry weight ratio of 2: 1, then pass into N 2 cause anaerobic state, N 2 The feed volume is the remaining volume after subtracting the effective volume from the total volume of the reactor. Ferment at 33°C. In the reactor, add raw materials intermittently and periodically to control the moisture content of cyanobacteria to 3% and the moisture content of livestock and poultry manure to 30%. .

Embodiment 2

[0019] Embodiment 2, blue-green algae and livestock and poultry manure are mixed in anaerobic reactor by dry weight ratio of 3: 1, then pass into N 2 cause anaerobic state, N 2 The feed volume is the remaining volume after subtracting the effective volume from the total volume of the reactor. Ferment at 37°C. In the reactor, add raw materials intermittently and periodically to control the moisture content of cyanobacteria to 4.5%, and the moisture content of livestock and poultry feces to 20%. .

Embodiment 3

[0020] Embodiment 3, blue-green algae and poultry excrement are mixed in anaerobic reactor by dry weight ratio of 2.5: 1, then pass into N 2 cause anaerobic state, N 2 The feed volume is the remaining volume after subtracting the effective volume from the total volume of the reactor. Ferment at 35°C. In the reactor, add raw materials intermittently and periodically to control the moisture content of cyanobacteria to 6% and the moisture content of livestock and poultry manure to 25%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com