Thermosetting solvent-free single-component substances and use thereof

A heat-curable, composition-based technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as slow curing speed, and achieve low curing temperature and time required for the bonding process. , beneficial effect on energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1 (comparative example)

[0051] A prior art composition consisting of epoxy resin and latent curing agent is intended to be considered as a comparative example. It consists of the following:

[0052] 67% mixture of bisphenol A- and bisphenol F-epoxy resins (EPR166 from Bakelite),

[0053] 27% latent amine curing agent (Ancamine 2014AS from Air Products),

[0054] 3.5% accelerator (dicyandiamide Dyhard SF 100 from Degussa),

[0055] 2.5% Thixotrope (Cab-O-Sil M5 from Cabot).

[0056] The following properties of the examples were determined:

[0057] 1. Curing peak

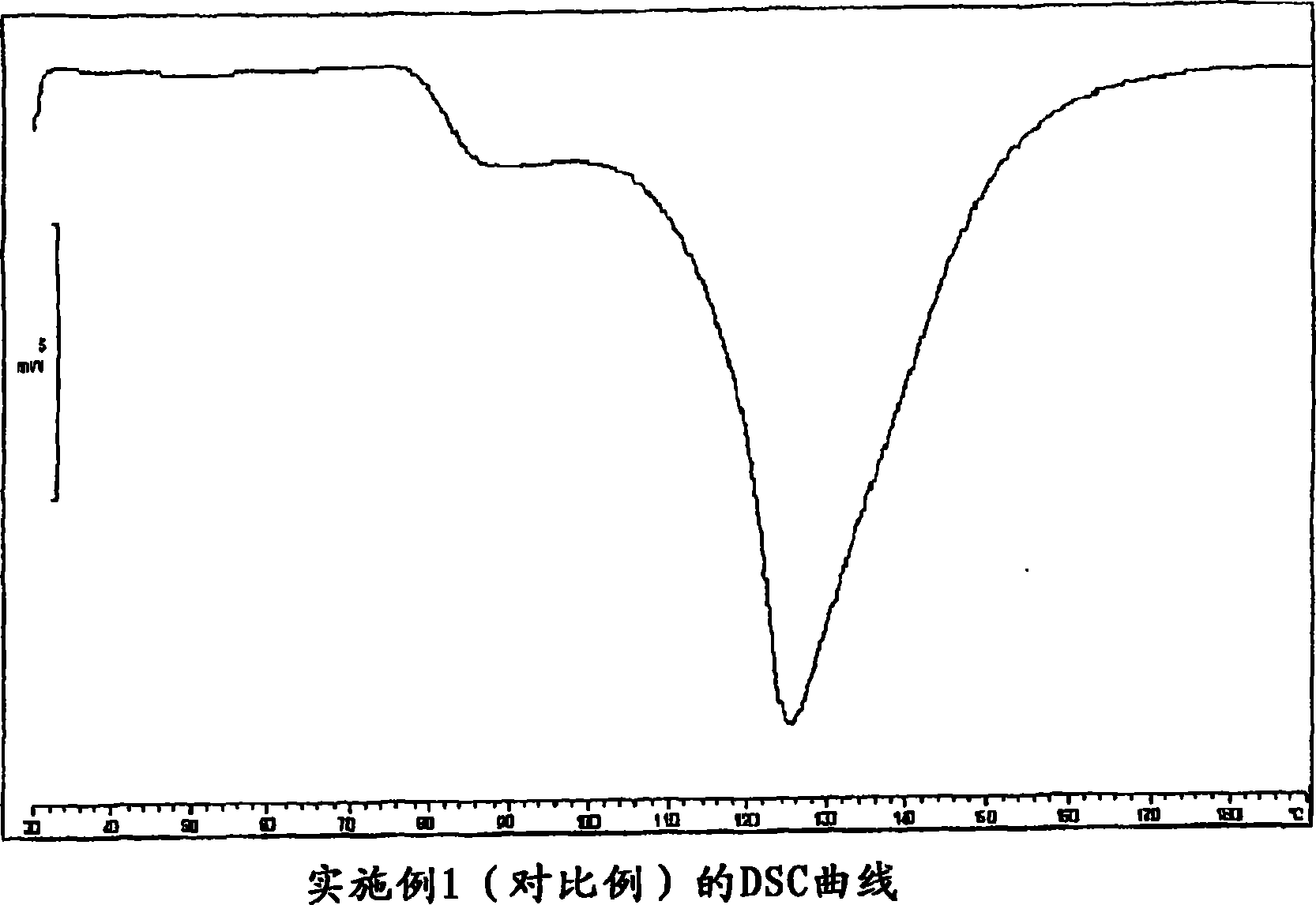

[0058] The reaction peaks of the comparative composition were measured on a DSC 822 type DSC instrument from the company Mettler-Toledo (DSC = Differential Scanning Calorimetry, Differential Thermal Analysis), as from figure 1 As can be seen from the shown DSC curve, the peak is located at about 125°C.

[0059] 2. Curing speed

[0060] The curing speed was measured in vibration mode at con...

Embodiment 2

[0064] The composition of the present invention consists of the following ingredients:

[0065] 73.5% MDI-based polyisocyanate (Desmodur VL R20, Bayer),

[0066] 24.5% latent amine curing agent (Ancamine 2014AS, Air Products),

[0067] 1.5% thixotropic agent (Cab-O-Sil M5, Cabot),

[0068] 0.5% adhesion promoter (Dynasilan Glymo, Degussa).

[0069] The DSC curve of this composition ( figure 2 ) showed a reaction peak temperature at 74°C, which was about 50°C lower than in the comparative example. This lower reaction temperature makes it possible to observe a significantly higher reaction rate than the comparative example. Depend on image 3 The rheometer curves give a cure time of about 60 seconds at 150° C. for the comparative example (right curve), while for the composition of the invention ( image 3 Middle left curve) cure time is only 10 seconds. The composition of the present invention takes about 60 seconds to cure at 120°C and 8 minutes at 80°C. Storage stabil...

Embodiment 3

[0071] The composition of the present invention consists of the following ingredients:

[0072] 65% IPDI-based polyisocyanate (Desmodur VP LS 2371, Bayer),

[0073] 33% latent amine curing agent (Adeka Hardener EH4337, Asahi Denka),

[0074] 1.5% thixotropic agent (Cab-O-Sil M5, Cabot),

[0075] 0.5% adhesion promoter (Dynasilan Glymo, Degussa).

[0076] Table 1 lists the most important properties of the composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com