Wireless passive sonic surface wave mixed parameter measuring sensor and parameters analysis method

A surface acoustic wave, wireless passive technology, used in radio wave measurement systems, radio wave reflection/re-radiation, measurement devices, etc., can solve the problems of complex sensor structure and inability to measure two physical quantities at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The content of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

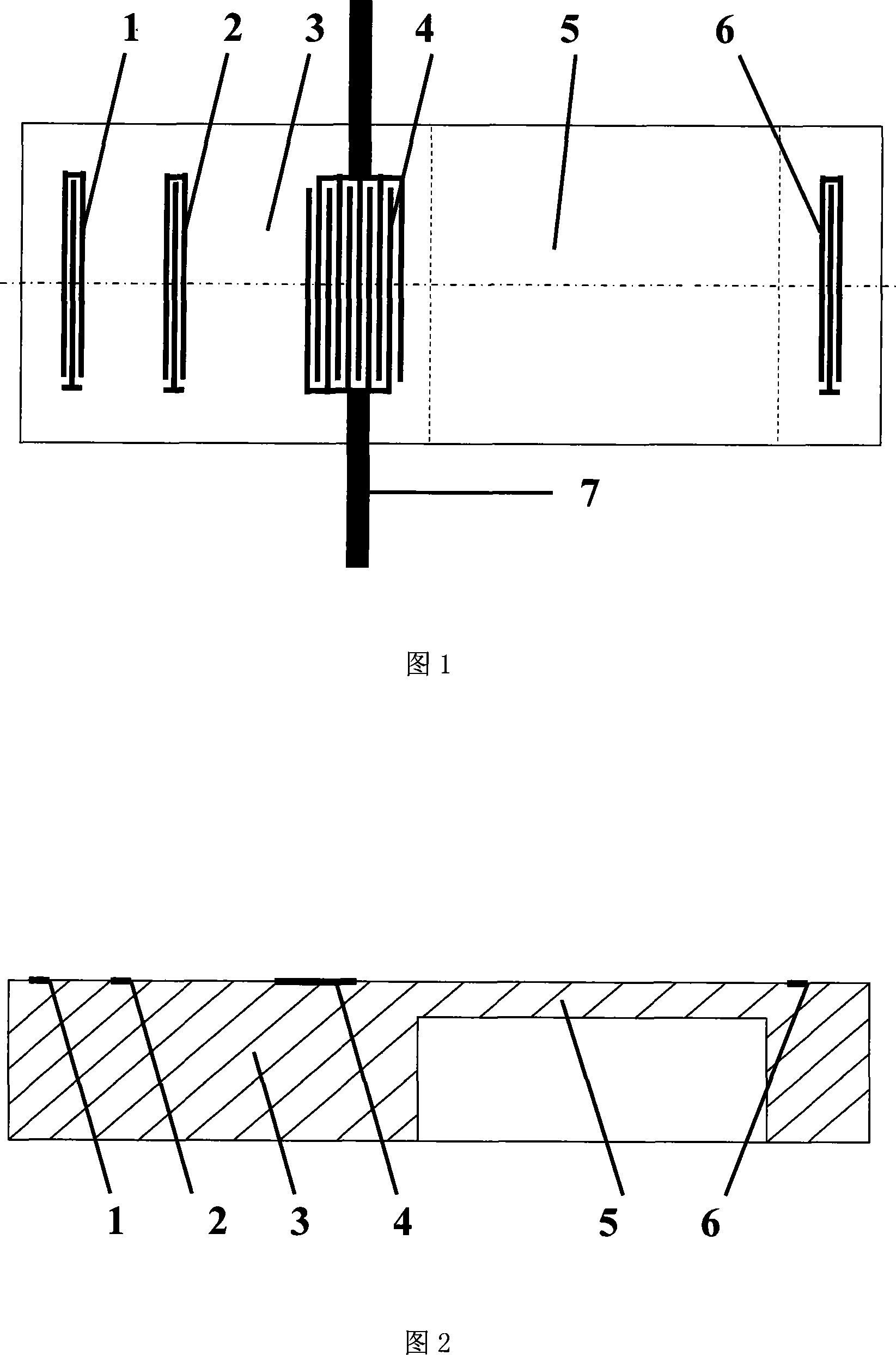

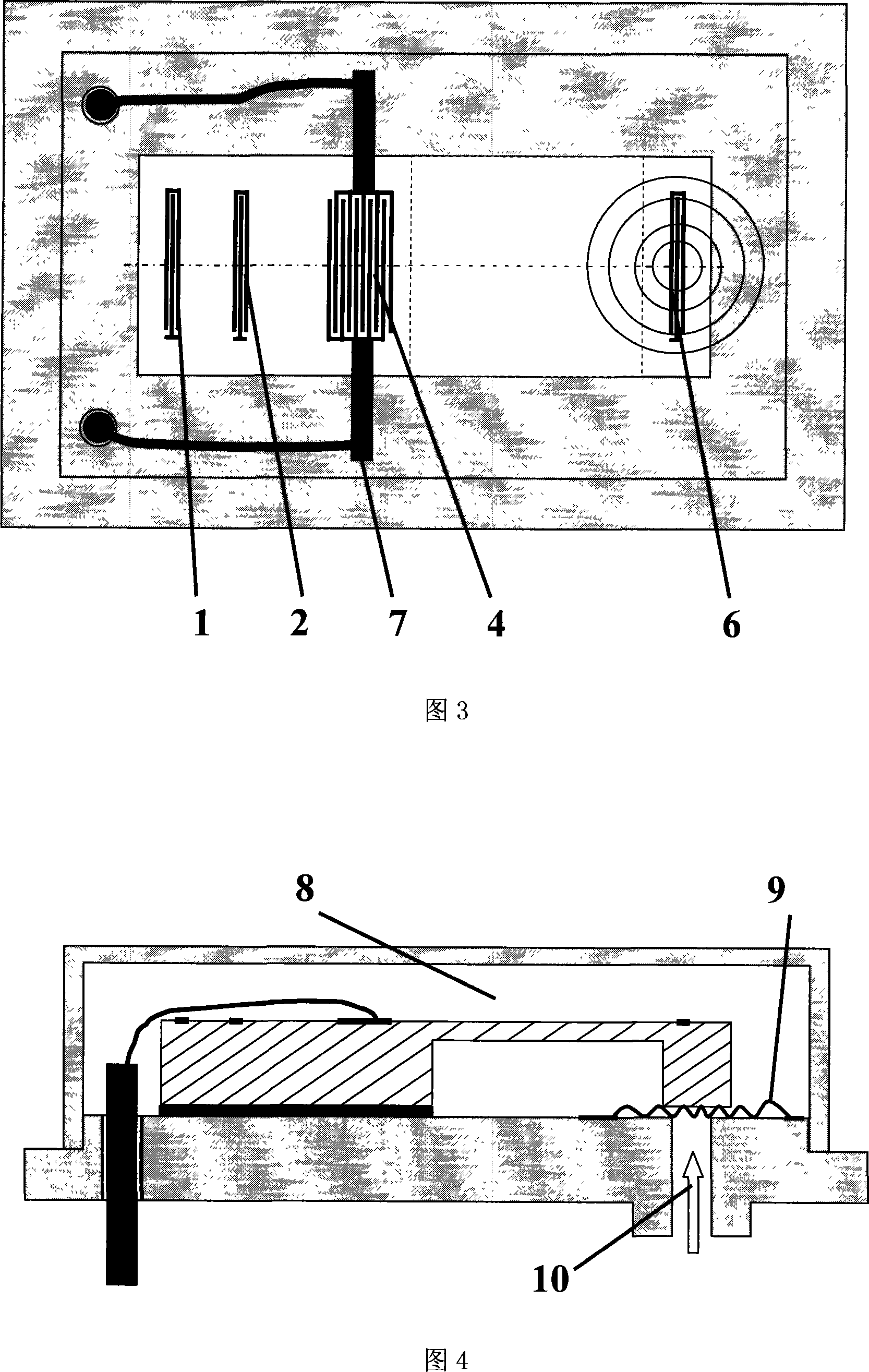

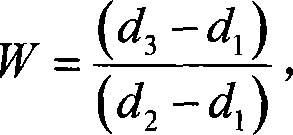

[0013] The embodiment of the invention is a wireless passive surface acoustic wave temperature and pressure parameter measurement sensor designed for a tire pressure monitoring system. Fig. 3 is a front view of the sensor package structure of the embodiment of the present invention, and Fig. 4 is a side view of the sensor package structure of the embodiment of the present invention.

[0014] The piezoelectric substrate 3 of the sensor is a lithium niobate piezoelectric crystal slice in the Y-cut Z direction. The reference reflector 2, the first reflector 1, the second reflector 6 and the interdigital transducer 4 are placed in the The piezoelectric substrate 3 has a metal aluminum film with a specific shape on it. The directions of the metal fingers of the reference reflector 2 , the first reflector 1 , the second reflector 6 and the I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com