Firedamp remote optical fiber laser detection instrument for mine

A fiber laser and detector technology, used in the measurement of color/spectral characteristics, etc., to achieve the effect of lengthening the effective absorption length and facilitating wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

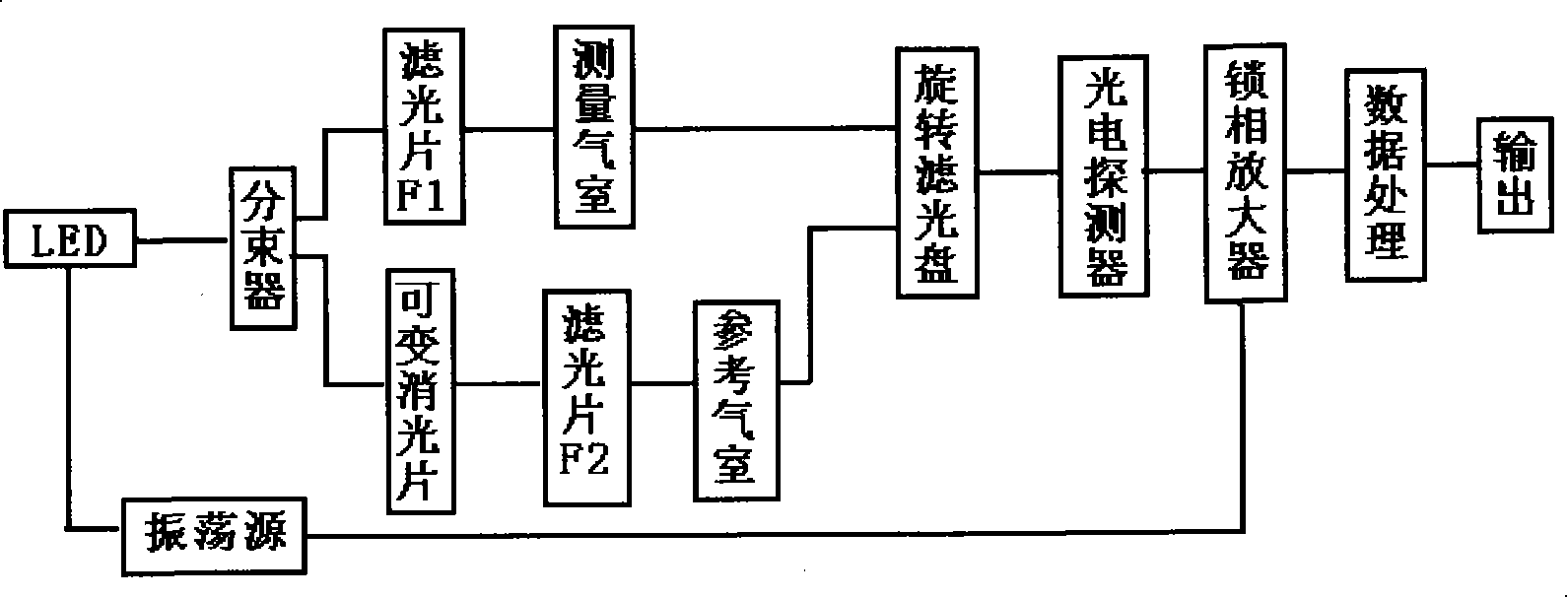

Method used

Image

Examples

Embodiment Construction

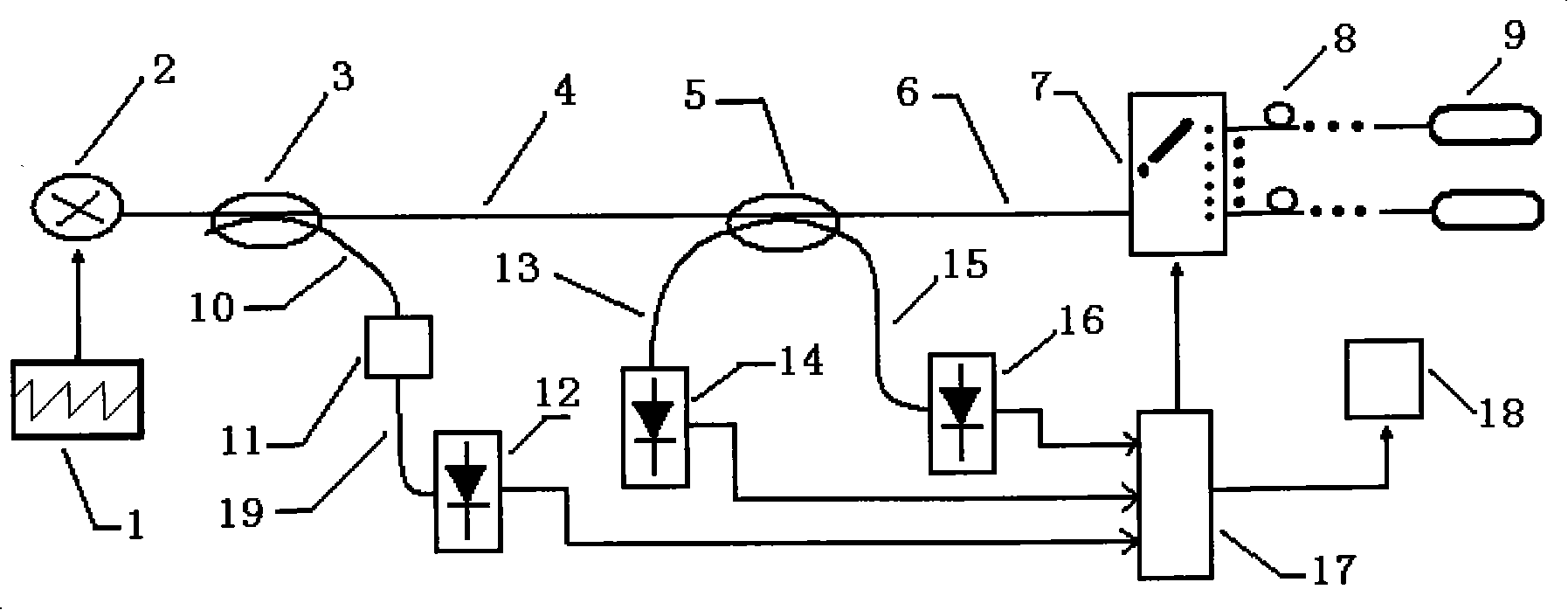

[0024] Schematic diagram of remote fiber laser detector for mine gas image 3 , which includes a distributed feedback semiconductor laser 2, a coupler, an optical switch 7, a photodetector, a data acquisition card 17, a computer 18, and the like. The distributed feedback semiconductor laser 2 is connected with the first coupler 3, the first coupler 3 is connected with the second coupler 5 through the second optical fiber 4, and the first coupler 3 is connected with the reference gas chamber 11 through the fourth optical fiber 10, from The light emitted by the reference gas chamber 11 is connected to the third photodetector 12 through the fifth optical fiber 19, and the second coupler 2 is connected to the mine optical cable 8 and the gas sensor probe 9 through the third optical fiber 6 through the optical switch 7. Connect with the first photodetector (16) through the sixth optical fiber 15, the light returned from the gas sensor probe 9 passes through the optical switch 7, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com