Method for characterization of thermoplasticity elastic body shape change chalasis

A technology of thermoplastic elastomer and thermoplastic elasticity, which is applied in the direction of testing the ductility of materials, special data processing applications, instruments, etc., and can solve problems such as large gaps between curves and experimental data points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1: PP modified SEBS elastomer material

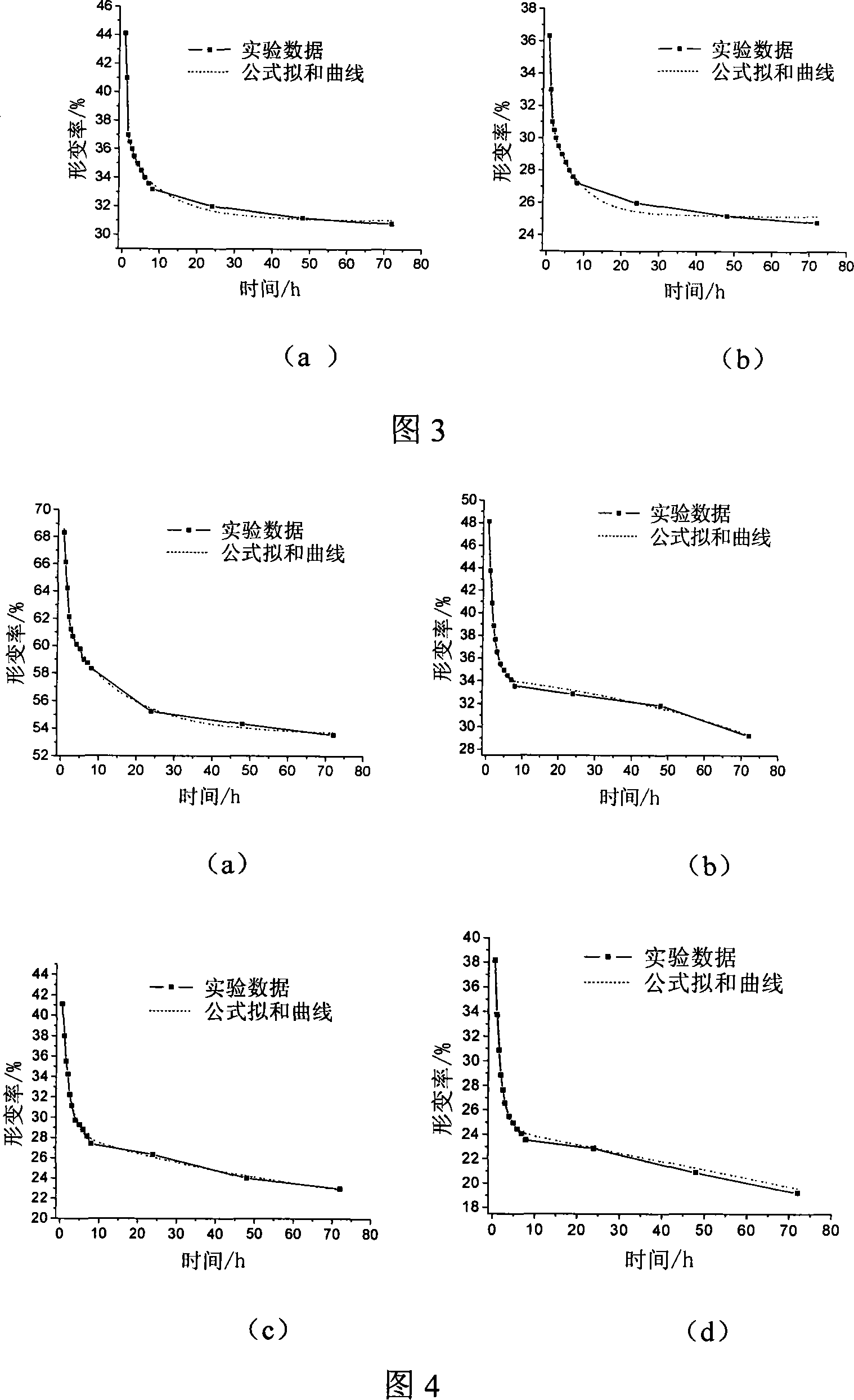

[0073] The two exponential decay functions in the mathematical software (see formula (2)) are fitted with the SEBS / PP compression set experimental data, and the results are shown in Figure 2. It can be seen from Figure 1 that the curve fitted according to formula (2) is in good agreement with the experimental data.

Embodiment 2

[0074] Embodiment 2: PP modified SEPS elastomer material

[0075] A large amount of experimental data obtained from the SEPS / PP deformation relaxation experiment was fitted to the mathematical model formula (Figure 3), and the fitted curve was in good agreement with the experimental data.

Embodiment 3

[0076] Embodiment 3: PP modified SBS elastomer material

[0077] The compression deformation relaxation experimental data of the SBS / PP elastomer material is fitted to the mathematical model formula (2), and the fitting curve shows that the experimental data curve and the formula fitting curve have a good degree of agreement (Figure 4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com