Method for detecting hub installing hole shape-location parameter based on picture recognition

A detection method and image recognition technology, applied in image data processing, image enhancement, character and pattern recognition, etc., can solve the problems of single function, expensive equipment, lack of automatic data processing ability, etc., to reduce labor intensity and efficiency. and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

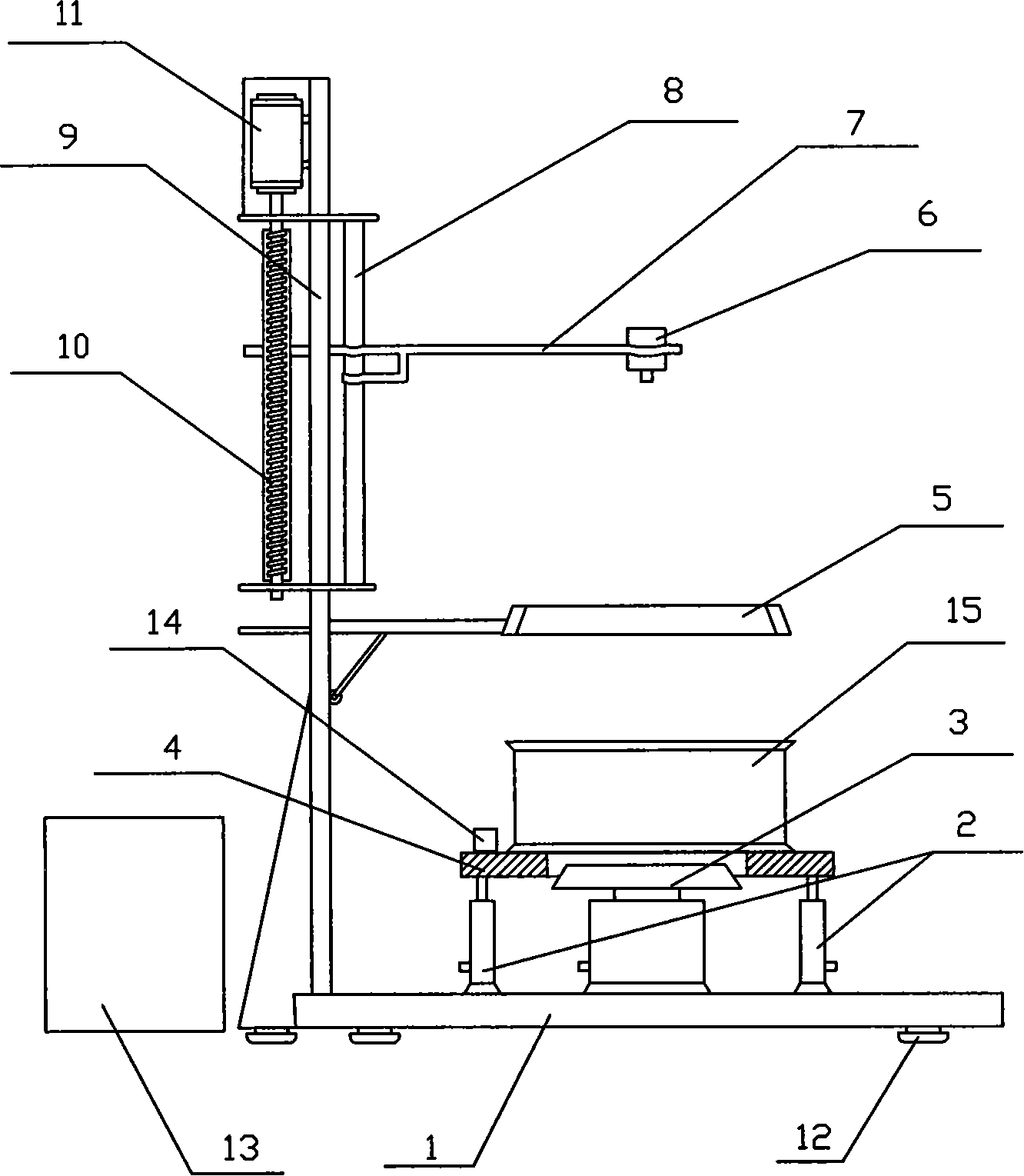

[0026] Such as figure 1 As shown, a vehicle hub detection device includes a base 1 on which a hub tray 4 with a lifting mechanism and a clamp 3 are arranged. The lifting mechanism is a cylinder 2, at least two cylinders 2, and one end of the cylinder 2 is vertical It is fixed on the base 1, and the other end is vertically fixed on the lower end surface of the hub tray 4, so that the hub tray is parallel to the horizontal plane.

[0027] The lower end surface of the base 1 is provided with a plurality of balance feet, at least three of which are convenient for placing the detection device stably.

[0028] The hub tray 4 is arranged around the fixture 3, and the hub tray 4 is provided with a distance-adjustable positioning block 14 for pre-positioning the hub during detection.

[0029] One end of the fixture 3 is vertically fixed on the base 1, and the other end is a truncated cone. The cone is provided with a multi-claw telescopic mechanism, and the top is provided with a pneu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com