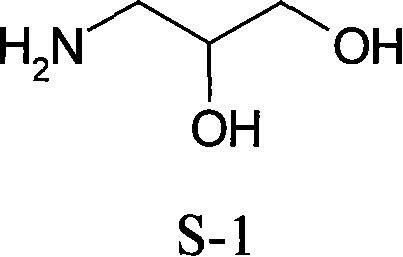

Method for synthesizing 3-amido-1,2-propanediol by pipe reactor

A technology of pipeline reactor and propylene glycol, which is applied in chemistry/physics/physicochemistry fixed reactor, preparation of functional groups substituted with amino groups, organic chemistry, etc., can solve the problems of poor reaction selectivity and many by-products, and achieve high yield The effect of high rate and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

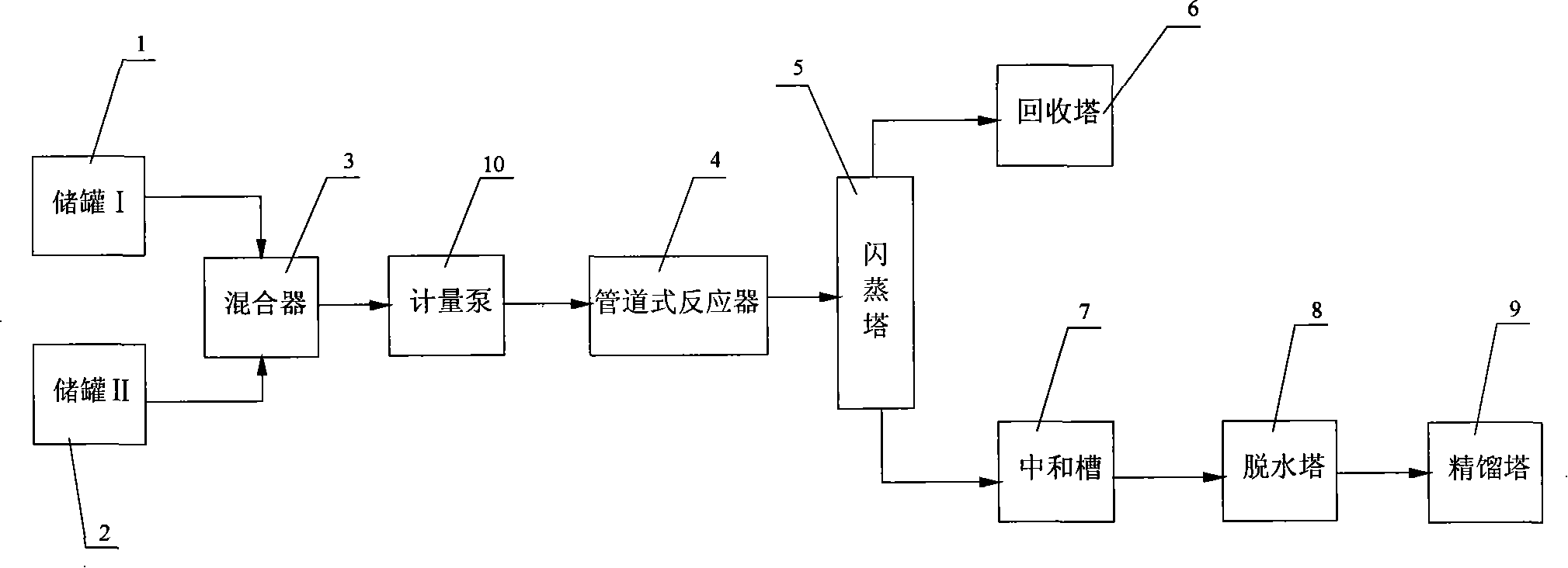

[0023] Embodiment 1, a kind of pipeline reactor synthetic 3-amino-1, the method for 2-propanediol, carry out following steps successively:

[0024] 1), ammoniation, namely the preparation of the mixed solution of 3-amino-1,2-propanediol and ammoniacal liquor:

[0025] The liquid phase chloroglycerol 55g (0.5mol) in the storage tank I 1 and the ammoniacal liquor of 40%wt in the storage tank II 2 are premixed earlier in the mixer 3 to form a reactant, and the mol ratio of chloroglycerin and ammonia is 1:10, mixer 3 is a static mixer. Then reactant is sent into pipeline reactor 4 with metering pump 10 and reacts, 70 ℃ of temperature of reaction, reaction pressure 4Mpa, pipeline reactor 4 is that an internal diameter is 4mm, the length is the cylindrical reactor of 30m; Control The flow rate of the metering pump 10 makes the flow rate of the reactant in the pipeline reactor 4 be 3.2l / h, even if the reaction time is about 7min; finally obtain the mixed solution of 3-amino-1,2-prop...

Embodiment 2

[0030] Embodiment 2, a method for synthesizing 3-amino-1,2-propanediol in a pipeline reactor, the device used is the same as in Example 1, and the following steps are carried out in sequence:

[0031] 1), ammoniation, namely the preparation of the mixed solution of 3-amino-1,2-propanediol and ammoniacal liquor:

[0032] After fully mixing chloroglycerin 55g (0.5mol) and ammonia water (80%wt) with a molar ratio of 1:15 (the molar ratio of chloroglycerin and ammonia), the reaction is carried out at a reaction temperature of 90°C and a reaction pressure of 6Mpa. The flow rate in the pipeline reactor 4 is 2.3 l / h, that is, the reaction time is controlled to be about 10 minutes; a mixed solution of 3-amino-1,2-propanediol and ammonia water is obtained.

[0033] 2), purification, i.e. the preparation of 3-amino-1,2-propanediol:

[0034] The above-mentioned mixed solution is returned to deamination through decompression flash evaporation; then the liquid obtained after the above-men...

Embodiment 3

[0035] Embodiment 3, a method for synthesizing 3-amino-1,2-propanediol in a pipeline reactor, the device used is the same as in Example 1, and specifically proceeds in the following steps:

[0036] 1), ammoniation, namely the preparation of the mixed solution of 3-amino-1,2-propanediol and ammoniacal liquor:

[0037] After fully mixing chloroglycerin 55g (0.5mol) and ammonia water (40%wt) with a molar ratio of 1:30 (the molar ratio of chloroglycerin and ammonia), the reaction is carried out at a reaction temperature of 80°C and a reaction pressure of 4Mpa. The flow rate in the pipeline reactor 4 is about 1.9 l / h, that is, the reaction time is controlled to be 12 minutes; a mixed solution of 3-amino-1,2-propanediol and ammonia water is obtained.

[0038] 2), purification, i.e. the preparation of 3-amino-1,2-propanediol:

[0039] The above-mentioned mixed solution is returned to deamination through decompression flash evaporation; then the liquid obtained after the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com