Non-phenols overlay film sand and producing method thereof

A production method and technology of coated sand, which are applied in casting molding equipment, molds, cores, etc., can solve the problems of lowering the melting point of coated sand, influence of the fluidity of coated sand, and increase of flue gas, etc., to achieve performance improvement, Good thermal stability and the effect of reducing smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: a kind of phenol-free coated sand is characterized in that it is made of silica sand, phenolic resin, urotropine, calcium stearate and polyethylene polyamine; wherein in every 100 kilograms of silica sand, add phenolic resin 2 kg, 0.3 kg of urotropine, 0.2 kg of calcium stearate, and 0.08 kg of polyethylene polyamine.

[0016] A kind of production method of above-mentioned phenol-free coated sand is characterized in that it is made of following steps:

[0017] (1) Heat the silica sand to 150°C;

[0018] (2) Add phenolic resin and polyethylene polyamine in proportion to the silica sand obtained in step (1), and mix uniformly;

[0019] (3) in the product that step (2) obtains, add the aqueous solution of urotropine in proportion, mix homogeneously;

[0020] (4) calcium stearate is added in proportion to the product obtained in step (3), mixed and broken;

[0021] (5) Sieve to obtain phenol-free coated sand.

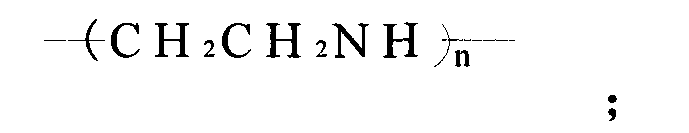

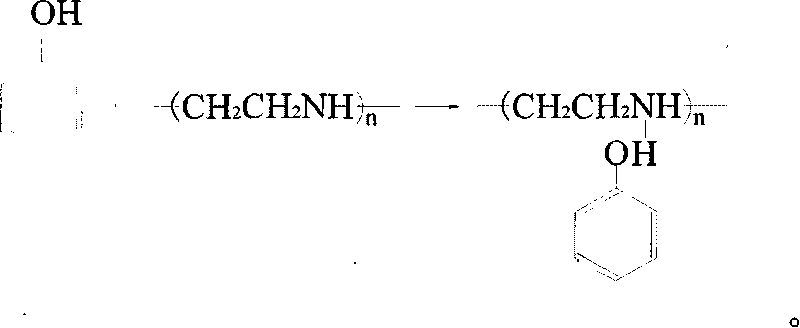

[0022] The molecular formula of polyethylene ...

Embodiment 2

[0026] Embodiment 2: a kind of phenol-free coated sand is characterized in that it is made of silica sand, phenolic resin, urotropine, calcium stearate and polyethylene polyamine; wherein in every 100 kilograms of silica sand, add phenolic resin 3 kg, 0.4 kg of urotropine, 0.3 kg of calcium stearate, and 0.09 kg of polyethylene polyamine.

[0027] A kind of production method of above-mentioned phenol-free coated sand is characterized in that it is made of following steps:

[0028] (1) Heat the silica sand to 160°C;

[0029] (2) Add phenolic resin and polyethylene polyamine in proportion to the silica sand obtained in step (1), and mix uniformly;

[0030] (3) in the product that step (2) obtains, add the aqueous solution of urotropine in proportion, mix homogeneously;

[0031] (4) calcium stearate is added in proportion to the product obtained in step (3), mixed and broken;

[0032] (5) Sieve to obtain phenol-free coated sand.

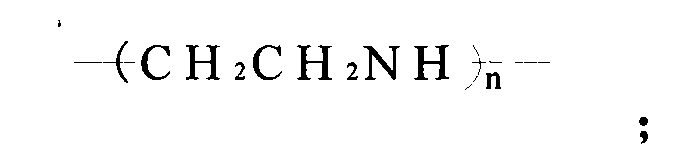

[0033] The molecular formula of polyethylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com