Oxidized starch modified phenolic resin lumber adhesion agent, preparation method and application thereof

A technology of wood adhesives and phenolic resins, applied in the direction of starch-derived adhesives, adhesives, aldehyde/ketone condensation polymer adhesives, etc., can solve the problems of lack of environmental protection resources for synthetic resin adhesives, and achieve poor water resistance and energy saving Energy and efficiency improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

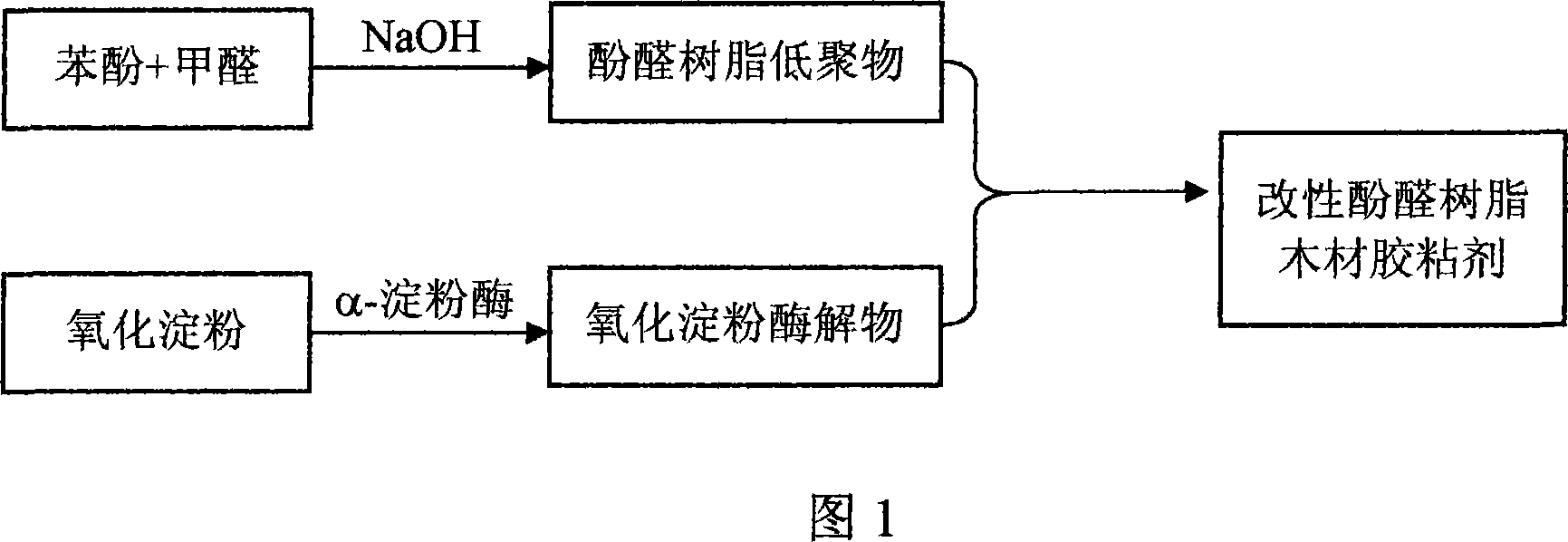

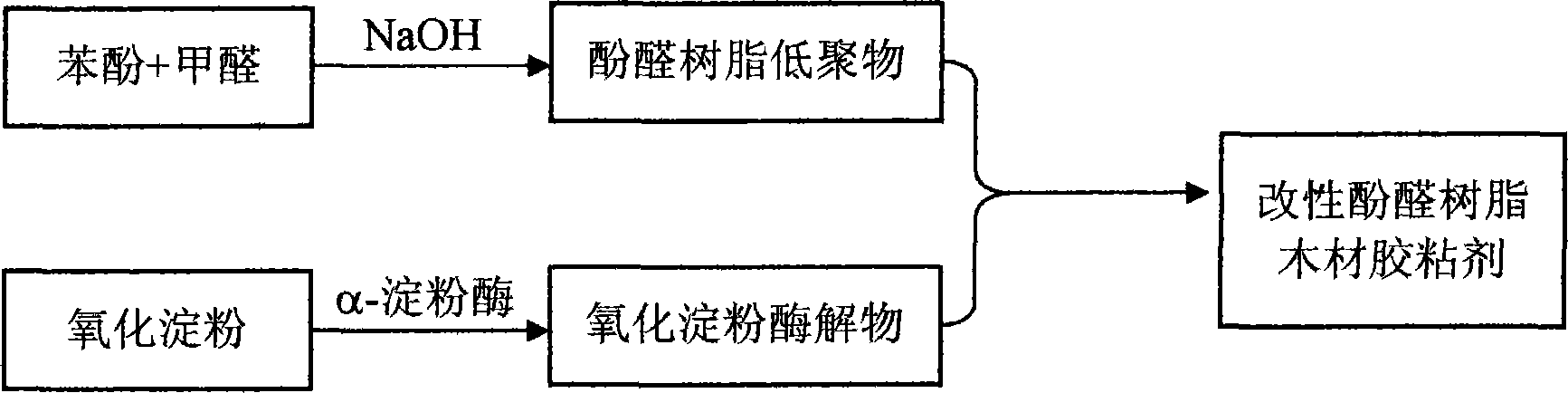

[0030] As shown in Figure 1, utilize the preparation method of oxidized starch modified phenolic resin wood adhesive, comprise the steps:

[0031] (1) Synthesis of phenolic resin oligomers. In a three-necked flask equipped with an electric stirrer, a thermometer, and a reflux condenser (dropping funnel), put molten phenol (37%) and formaldehyde solution with a molar ratio of 1: 2.4 and place them in a constant temperature water bath. Add 50% sodium hydroxide solution from the dropping funnel while stirring to make the pH value 9.5, then raise the temperature to 75°C, keep it warm for 60min to carry out the addition reaction of formaldehyde and phenol, then raise the temperature to 95°C, and keep the temperature for 30min while stirring , to further condense polymethylol phenol into phenolic resin oligomers. After the reaction is completed, cool down to 40°C and discharge; then use a rotary evaporator to distill water, free phenol, and free aldehyde to obtain a liquid with a v...

Embodiment 2

[0051] Utilize the preparation method of oxidized starch modified phenolic resin wood adhesive, comprise the steps:

[0052] (1) Synthesis of phenolic resin oligomers. In a three-necked flask equipped with an electric stirrer, a thermometer, and a reflux condenser (dropping funnel), put molten phenol (37%) and formaldehyde solution with a molar ratio of 1: 2.6 and place it in a constant temperature water bath. Add 50% sodium hydroxide solution from the dropping funnel while stirring, so that the pH value is 11, then raise the temperature to 80°C, keep it warm for 40min to carry out the addition reaction of formaldehyde and phenol, then raise the temperature to 90°C, and keep the temperature for 40min while stirring , to further condense polymethylol phenol into phenolic resin oligomers. After the reaction was completed, the temperature was lowered to 40°C and the material was discharged. Then use a rotary evaporator to distill water, free phenol, and free aldehyde to obtain ...

Embodiment 3

[0059] Utilize the preparation method of oxidized starch modified phenolic resin wood adhesive, comprise the steps:

[0060] (1) Synthesis of phenolic resin oligomers. In a three-necked flask equipped with an electric stirrer, a thermometer, and a reflux condenser (dropping funnel), put molten phenol (37%) and formaldehyde solution with a molar ratio of 1: 1.4 in a constant temperature water bath, and Add 50% sodium hydroxide solution from the dropping funnel while stirring to make the pH value 9, then raise the temperature to 60°C, keep it warm for 60min to carry out the addition reaction of formaldehyde and phenol, then raise the temperature to 100°C, and keep the temperature for 20min while stirring , to further condense polymethylol phenol into phenolic resin oligomers. After the reaction was completed, the temperature was lowered to 40°C and the material was discharged. Then use a rotary evaporator to distill water, free phenol, and free aldehyde to obtain a liquid with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com