Malodorous gas processing assembly technique

A malodorous gas and combined process technology, which is applied in the field of combined process for malodorous gas treatment, can solve problems such as malodorous gas pollution, and achieve the effects of compact equipment structure, easy handling, and reduction of equipment investment costs and device operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

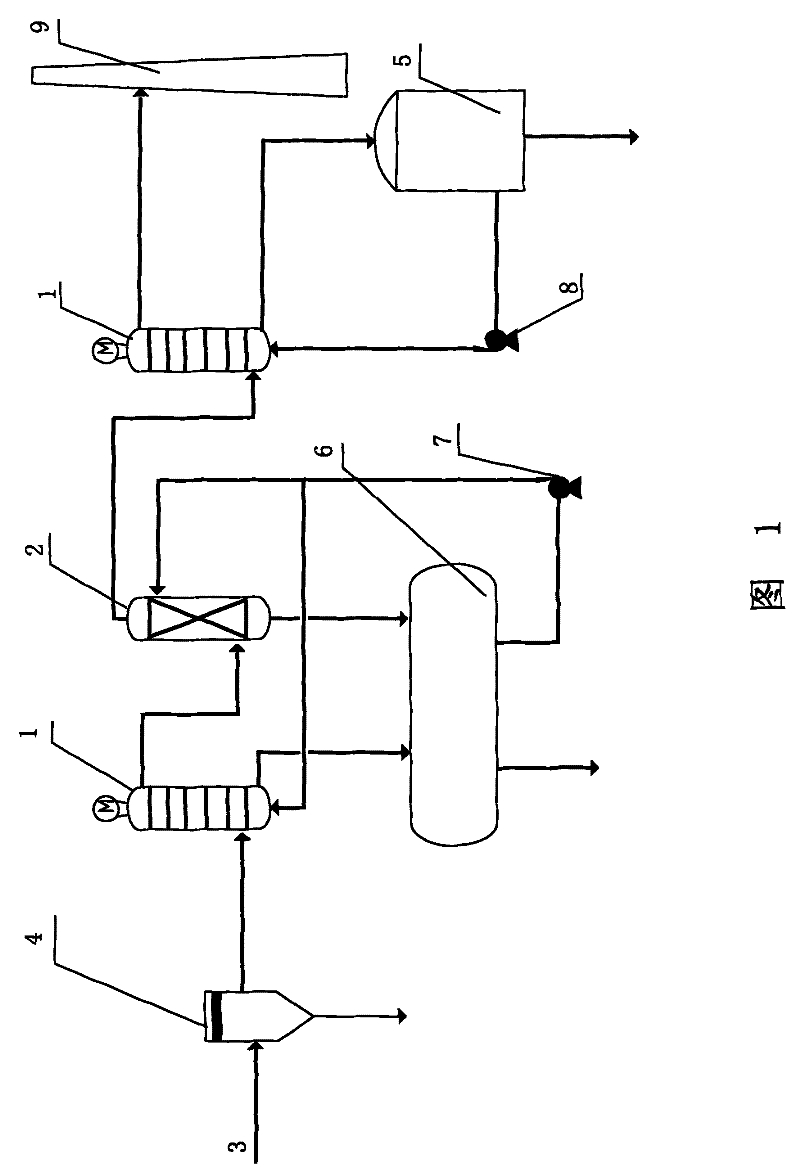

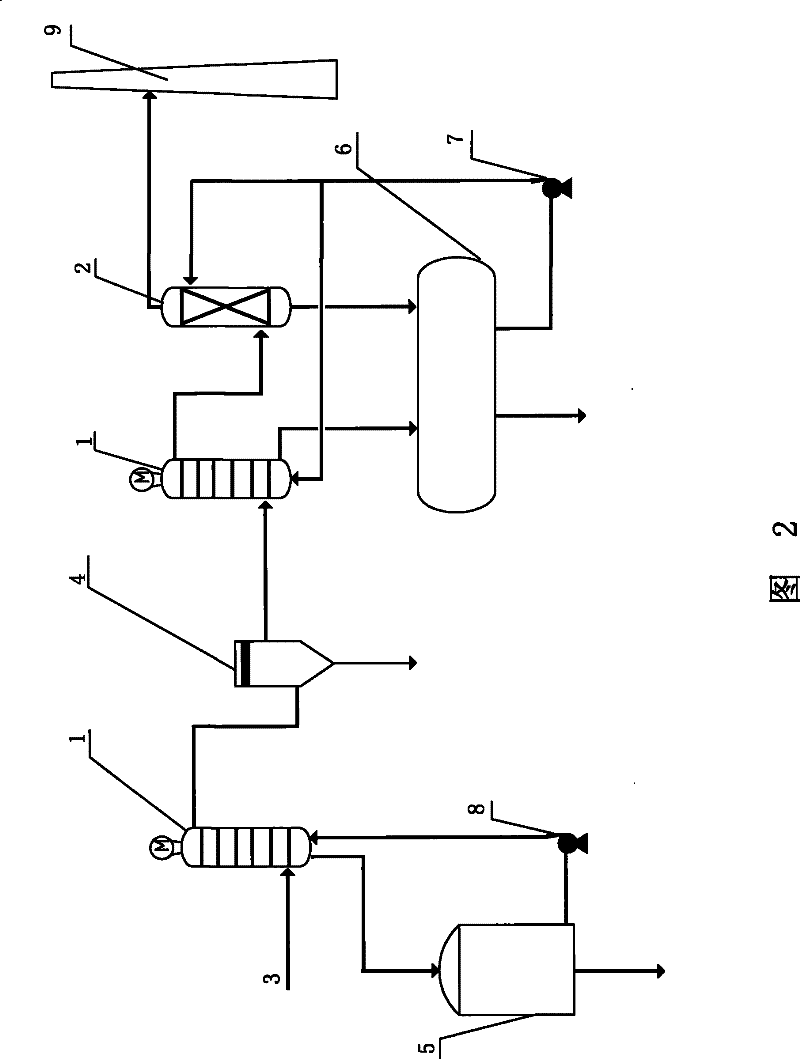

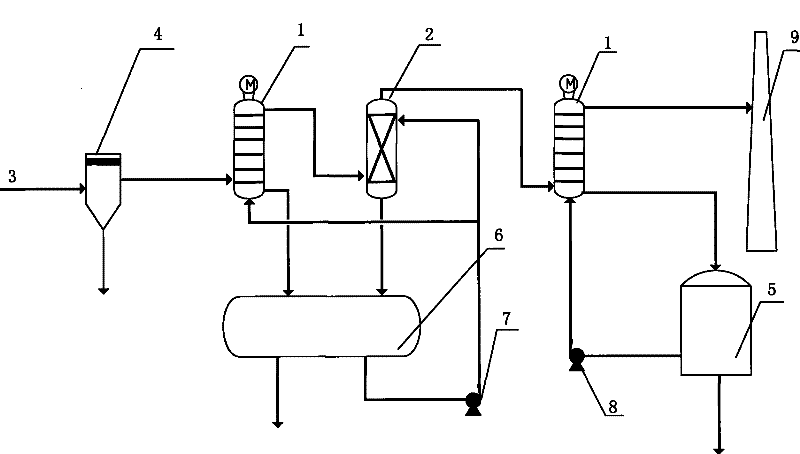

[0018] Such as figure 1 As shown, the malodorous gas 3 uses its own pressure to enter the lower part of the gas-liquid separator 4, and the gas and liquid are separated in the gas-liquid separator 4. The separated gas comes out of the upper part of the gas-liquid separator 4 and enters the supergravity rotation The bottom of bed 1 reacts with solvent A under the effect of bed atomization, and the volume ratio of solvent A to the malodorous gas entering the supergravity rotating bed 1 is 4-20l / m 3 This is the first-level absorption. The reacted liquid phase enters the A solvent tank 6 and contacts with the solvent A countercurrently. After treatment, it returns to the supergravity rotating bed 1 under the action of the solvent A circulation pump 7 for recycling, and is treated by the solvent A The latter gas enters the packed absorption tower 2 with a residence time of 1 to 3 seconds, which can ensure the absorption effect of low-concentration gas. The liquid phase in the packed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com