Method for detecting heat transfer resistance/heat transfer factor of building enclosure structure by infrared thermal imaging system

A technology for building envelope structure and infrared thermal imaging camera, which is applied in the direction of thermal conductivity of materials, instruments, and thermal development of materials, etc., can solve the problems of difficult data reliability, difficult operation, and difficulty, so as to overcome the large error of test data. , The effect of fast detection and accurate test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

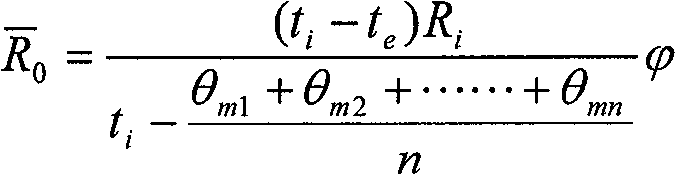

[0052] The requirements of the heat flow meter method are the same, and the detection condition requires one-dimensional steady-state heat transfer.

[0053] First of all, sampling points are selected for the enclosure structure. The area of the detection area should be able to represent the thermal characteristics of the enclosure structure to be detected. The aspect ratio of the area should be consistent with the aspect ratio of the display window of the infrared thermal imager, so that the detection area Display window filled with thermal imaging cameras.

[0054] Before selecting a point, observe the detection area with an infrared thermal imager (FLUCK Ti45 type in the United States), so that the geometric center of the selected area does not have an extreme temperature area (highest temperature or lowest temperature), and mark the selected area, you can use a A heating wire is formed around the selected area, which will be clearly visible in the window of the thermal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com