Three-dimensional high-flux medicaments sifting chip and manufacture method thereof

A high-throughput, chip-based technology, applied in biochemical equipment and methods, biomass post-processing, biological material pre-treatment, etc., can solve the problems of large consumption of reagents and drugs, high development cost, and long screening cycle. Achieve the effects of increasing stability and smoothness, reducing channel internal resistance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The manufacturing steps of the high-throughput drug screening chip in the present invention are as follows:

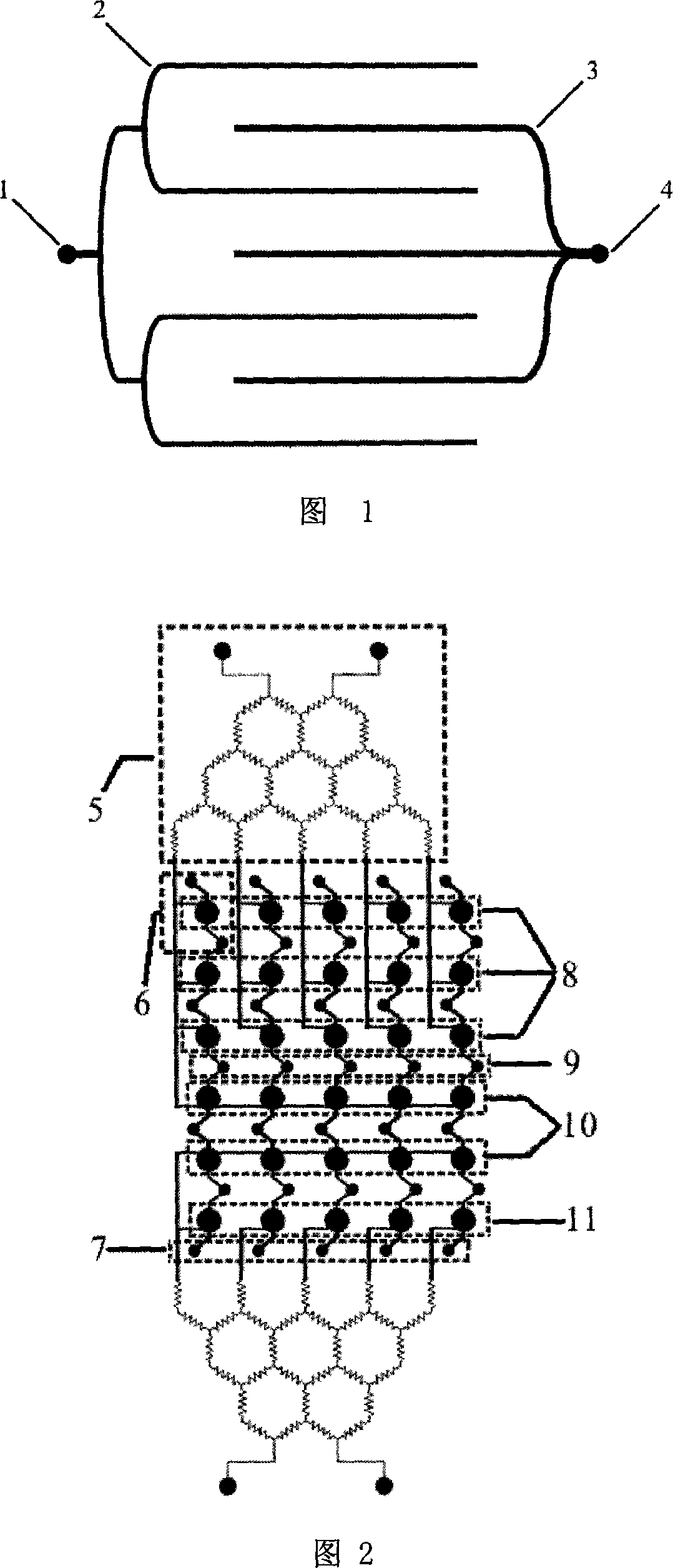

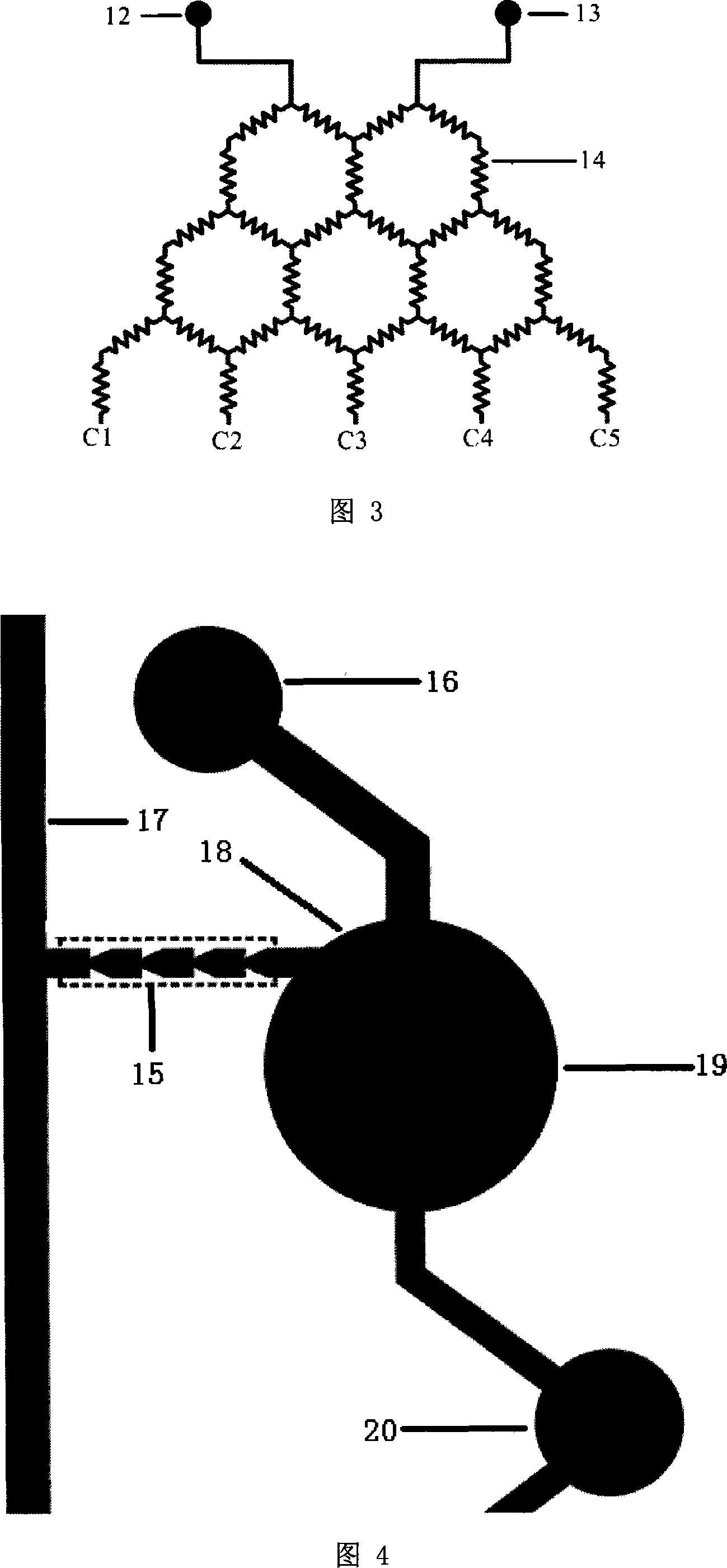

[0031] (1) Use the Coredraw drawing software to design the channel graphics as shown in Figure 1 and Figure 2. The cell injection and waste liquid output channels shown in Figure 1 are smooth bifurcated structures, and the cell injection port 1 leads to two cells into the tributary channel Channel 2, each cell is injected into the tributary channel, and two cells are respectively injected into the tributary channel, and the waste liquid outlet 4 leads to three waste liquid branch channels 3 . The channel shown in Figure 2 includes a concentration gradient channel 5, a quantitative cell culture chamber 6, a cell injection hole 7, a waste liquid outlet hole 9, and three groups of cell culture parallel chambers 8 composed of cell culture chambers. , two groups of blank control chambers 10 and positive drug control cell culture chambers 11 . As shown in Figure 3, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com