Dust-collecting equipment

The technology of a dust removal device and a dust hood is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators. , Small footprint, no noise pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

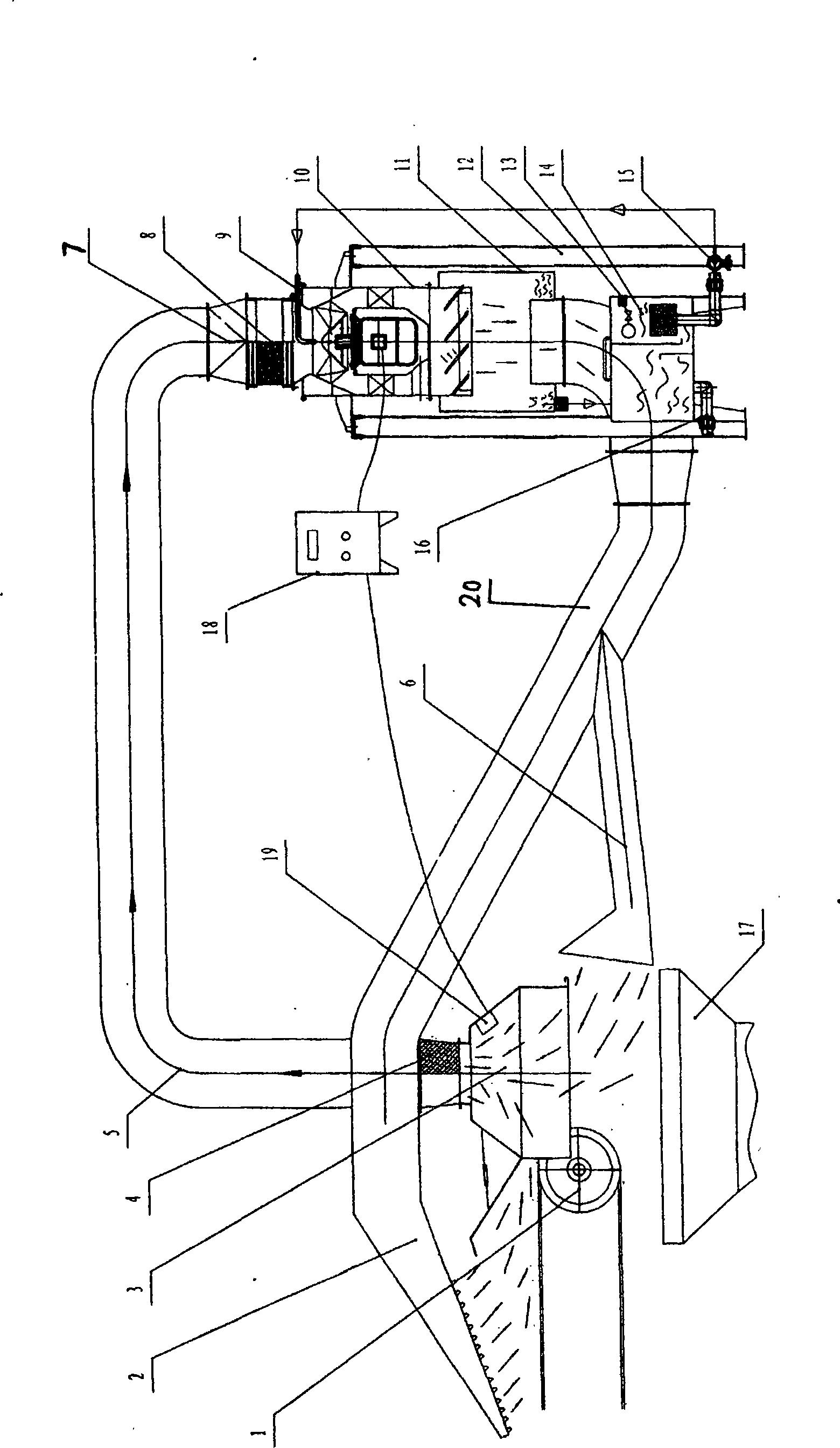

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] As shown in the drawings: the present invention is composed of a suction pipe 5, a dust removal scrubber 10, a dehydrator 11, a circulating water tank 14 and a return air pipe 20. One end of the suction pipe 5 is connected to the dust collection hood 3, and the other end is connected to the dust removal washing machine. The air machine 10 and the dehydrator 11, the dehydrator 11 is connected to the return air duct 20 and the circulating water tank 14, the return air duct 20 is provided with the return air hood 2 and the return air hood 6, and the dust collection hood 3 is provided with a pulverized coal concentration sensor 19. The frequency converter 18 is connected to the motor of the dust removal scrubber 10 and the pulverized coal concentration sensor 19 , the water inlet pipe 9 arranged on the dust removal scrubber 10 is connected to the circulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com