A making system for line organic luminescent display

A light-emitting display and manufacturing system technology, applied in the direction of electroluminescent light source, light source, electric light source, etc., can solve the problems of instability, movement, and low production efficiency of related components, and achieve smooth and fast transmission, simple system maintenance, and internal The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

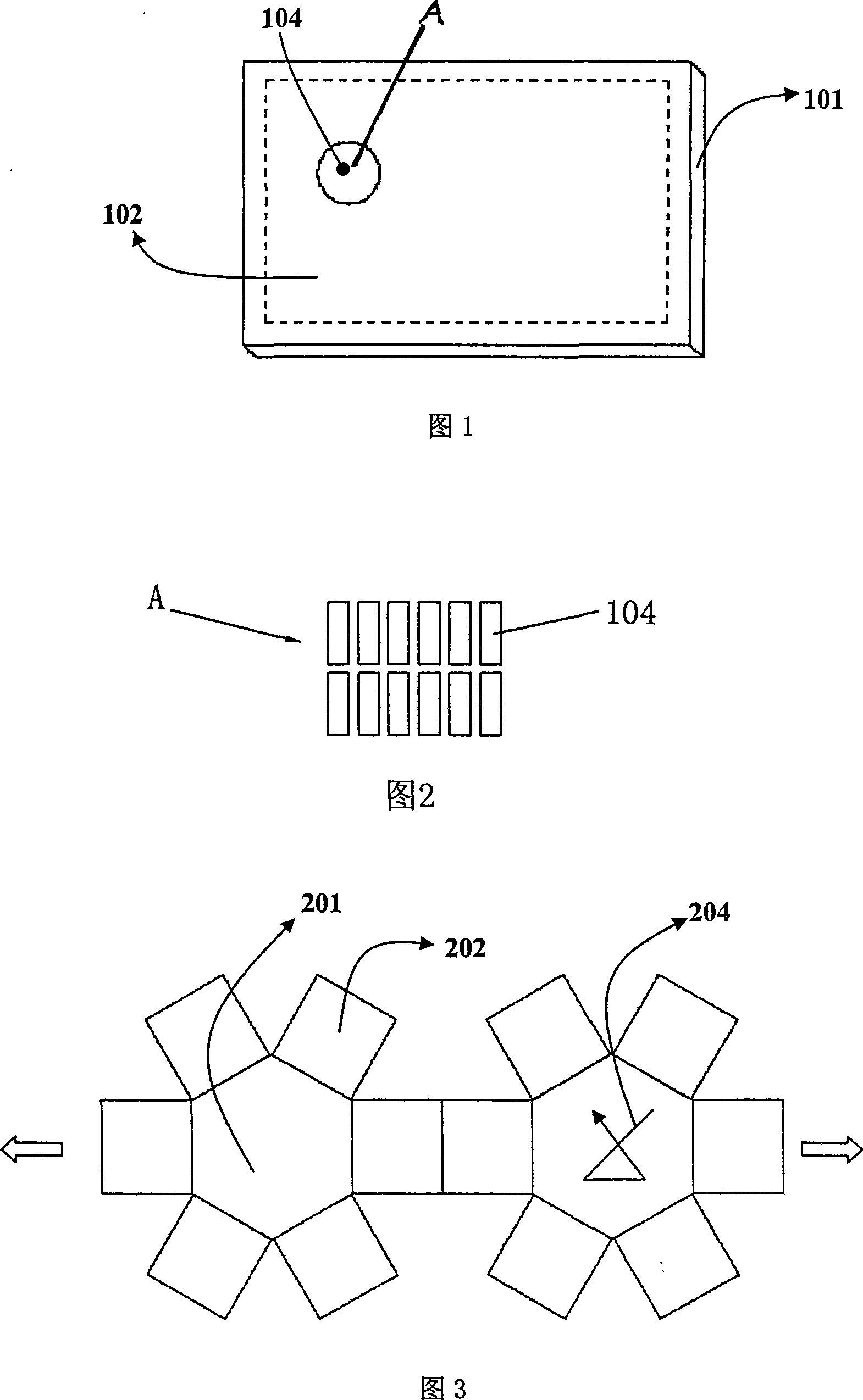

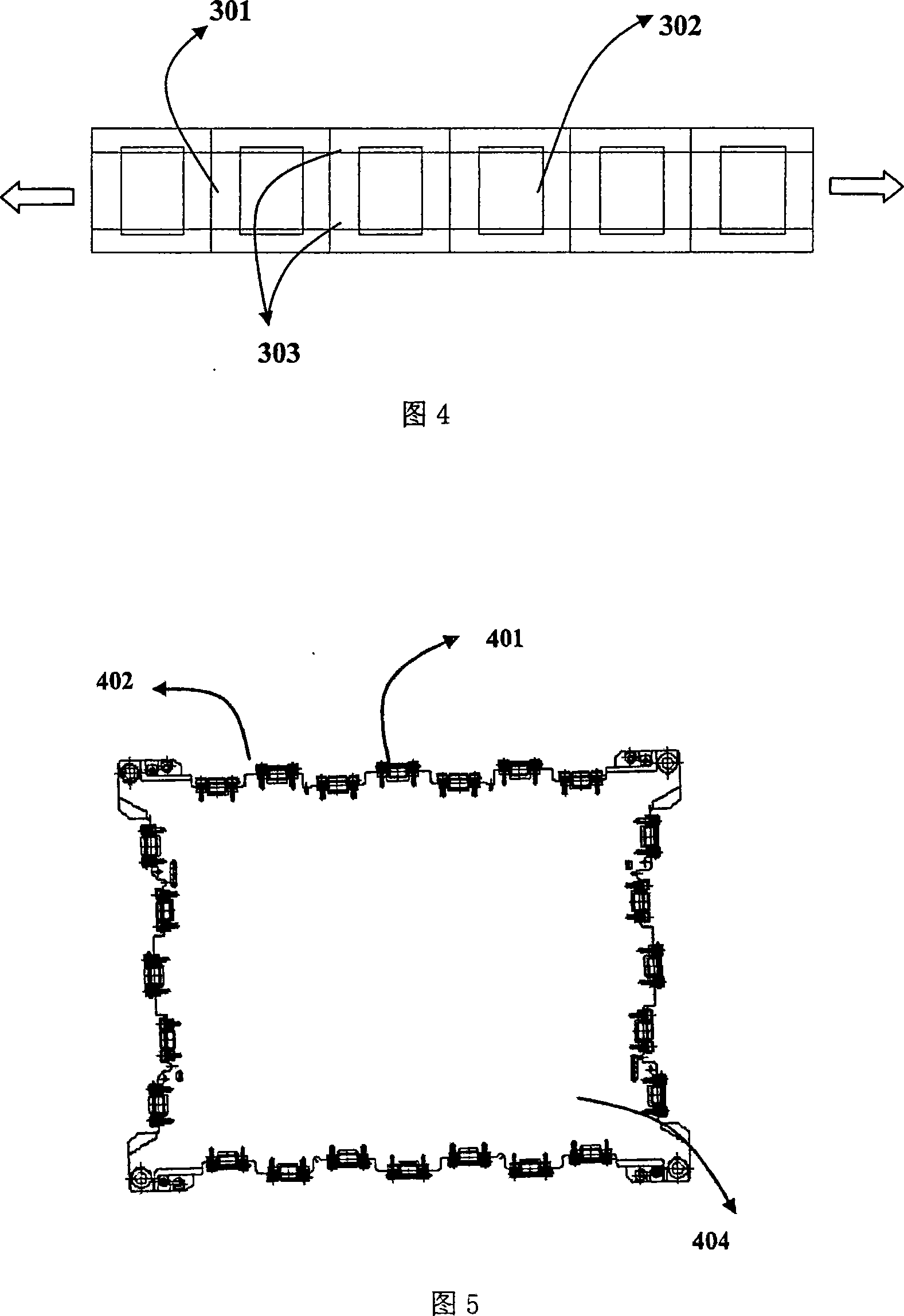

[0033] A linear organic light emitting display manufacturing system, the manufacturing system has a fixed mask plate holder 601 in its processing module. As shown in FIG. 7 and FIG. 8 , the mask plate holder 601 is fixed at the bottom of the processing module. The fixed mask holder 601 has a design of a square ring with a support platform 602 open on one side, that is, the mask holder 601 has a square ring with an open side, and the square ring of the mask holder 601 A support platform 602 for placing a mask plate is extended from the inner side of the ring. Except for changing the mask 102 , the mask 102 is always fixed in the square ring of the mask holder 601 . The function of the support table 602 is to hold the mask frame 101 .

[0034] A mask rolling pin 606 may also be provided on the support table 602 of the mask holder 601, and the mask rolling pin 606 helps the mask 102 to move in and out smoothly without generating rubbing debris or causing the frame to scratched....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com