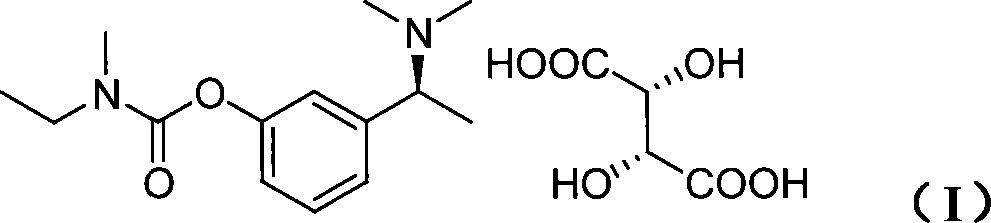

Technique for producing rivastigmine hydrogen tartrate

A kind of rivastigmine bitartrate, the technology of production technology, is applied in the field of the production technique of rivastigmine bitartrate, can solve the problems of high market price, high production cost of rivastigmine bitartrate, etc., to achieve improved utilization rate, low cost, pollution small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

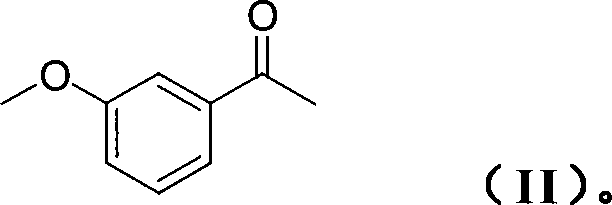

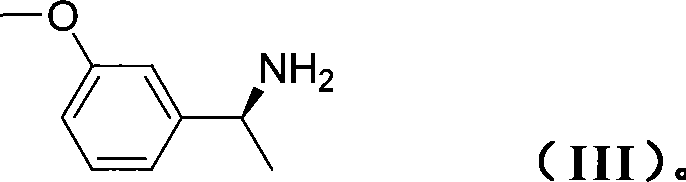

[0035] 1. Preparation of (S)-1-(3-methoxyphenyl)ethylamine (compound 1)

[0036] 15g (0.1mol, purity 98%) of m-methoxyacetophenone was dropped into the reactor, ethyl acetate 200mL and chiral auxiliary agent 0.12mol were heated to reflux, and HPLC monitoring m-methoxyacetophenone had reacted completely. The compound obtained by the reaction treatment is put into a reactor for catalytic hydrogenation. Put the hydrogenated product into the reactor, add 300mL of THF to dissolve it, and control the temperature at 0-10°C. 50.6 g (0.5 mol, reagent grade) of triethylamine was added, followed by dropwise addition of 61.3 g (0.4 mol, reagent grade) of phosphorus oxychloride, and then the temperature was raised to reflux for 5 h. Concentrate and recover THF, and extract with dichloromethane to obtain compound 1 with a yield of 80.6% and a purity of 98%.

[0037] 2. Preparation of (S)-1-(3-methoxyphenyl)-N,N-dimethylethylamine (compound 2)

[0038] In a 100mL three-necked flask, add c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com