Method for processing recombination dried shrimps

A processing method and dried shrimp technology, applied in the processing field of reconstituted dried shrimp, can solve the problems such as no patent literature report of dried dried shrimp, and achieve the effects of better taste, prevention of oxidative deterioration and both taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

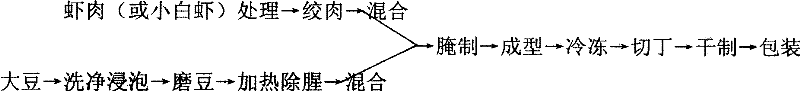

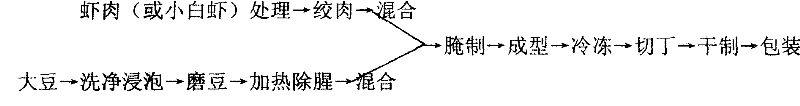

[0027] as per figure 1 The shown process flow diagram of the recombined dried shrimp processing method includes the following steps in turn:

[0028] (1) Choose 100kg of shrimp meat or small white shrimp as raw material, use a meat grinder to grind it into meat filling, and make it into minced meat; after selecting 30kg of soybeans, wash them with clean water and soak them for about 8 hours to make the moisture content of soybeans reach 50% , and then use a refiner to grind the bean paste into bean paste, and then heat the bean paste to 100°C for 4 minutes to remove the beany smell.

[0029] The scientific name of small white shrimp is the collective name of the hairy shrimp genus of Crustacea (Crustacea) decapoda (Decapoda) cherry shrimp family (Sergestidae). Also known as water shrimp, small economical shrimp. The dry product is called shrimp skin.

[0030] (2) Put the shrimp meat filling and bean paste into the blender, add 1.5kg of refined salt, 5kg of sugar, 200g of a...

Embodiment 2

[0035] as per figure 1 The shown process flow diagram of the recombined dried shrimp processing method includes the following steps in turn:

[0036] (1) Use 100kg of shrimp meat or small white shrimp as raw material, use a meat grinder to grind it into meat filling, and make it into minced meat; after selecting 20kg of soybeans, wash them with clean water and soak them for about 6 hours to make the moisture content of soybeans reach 40%. , and then use a refiner to grind the bean paste, and then heat the bean paste to 100°C for 5 minutes to remove the beany smell.

[0037] (2) Put the shrimp meat filling and bean paste into the blender, add 0.5kg of refined salt, 3kg of sugar, 150g of animal protein extract, 0.1kg of ginger powder, 0.15kg of monosodium glutamate, 0.05kg of sodium benzoate and 80g of chili powder, and stir well Then marinate for about 8 hours at a low temperature of 1°C.

[0038] (3) Pour the mixed meat stuffing obtained in step (2) into an independent form...

Embodiment 3

[0042] as per figure 1 The shown process flow diagram of the recombined dried shrimp processing method includes the following steps in turn:

[0043] (1) Choose 100kg of shrimp meat or small white shrimp as raw material, use a meat grinder to grind it into meat filling, and make it into minced meat; after selecting 40kg of soybeans, wash them with clean water and soak them for about 10 hours, so that the moisture content of soybeans reaches 60% , and then use a refiner to grind the bean paste, and then heat the bean paste to 100°C for 5 minutes to remove the beany smell.

[0044] (2) Put the shrimp meat filling and bean paste into the blender, and add 2kg of refined salt, 7kg of sugar, 250g of animal protein extract, 0.3kg of ginger powder, 0.25kg of monosodium glutamate, 0.15kg of sodium benzoate and 120g of chili powder, and stir well Marinate at a low temperature of 3°C for about 16 hours.

[0045](3) Pour the mixed meat stuffing obtained in step (2) into the overall for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com