Method and device for extracting a metal from a slag containing the metal

A technology for extracting metals and slag, applied in lighting and heating equipment, etc., can solve problems such as limiting phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

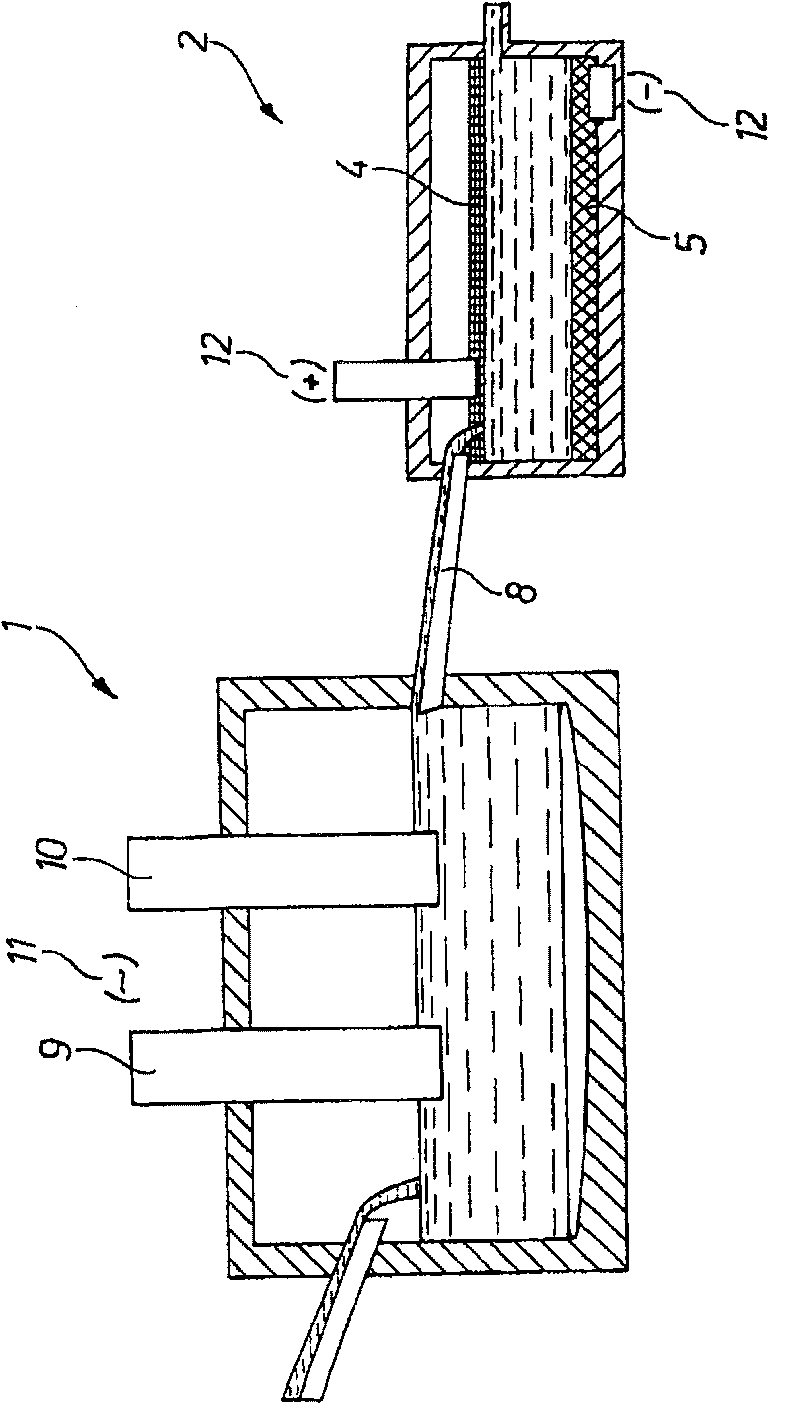

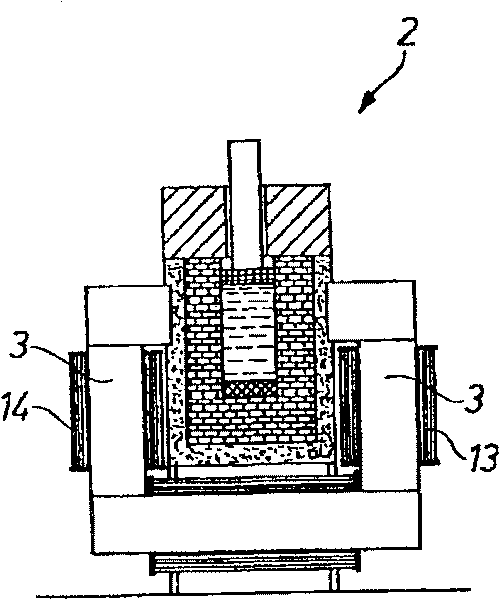

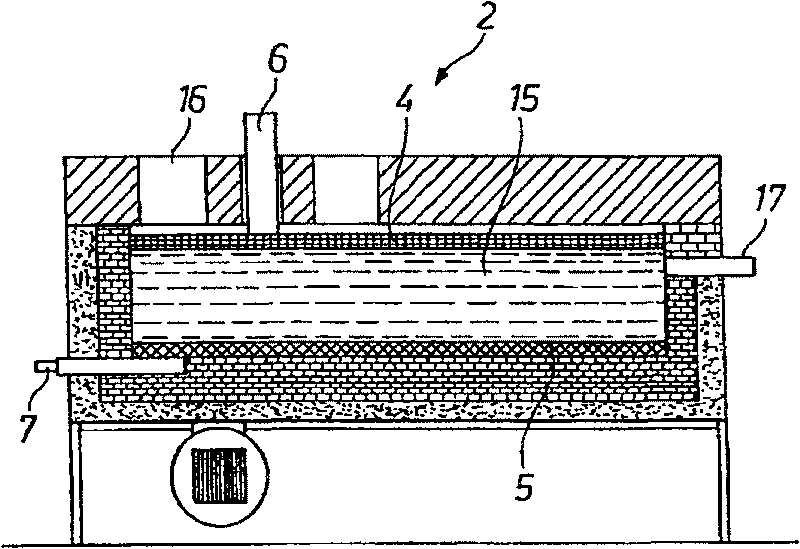

[0079] The slag obtained from the smelting of the concentrate in the rapid smelting plant contains 4% Cu and 15% Fe 3 o 4 . All slag was drained in 3 hours and exported to a 9.5 MVA three-phase AC electric arc furnace 1 through a slagging tank. The slag output is 30t / h, that is, 90t is processed in each cycle. Coke consumption reaches about 8 kg / t and energy consumption reaches about 70 kWh / t, corresponding to an average power consumption of 6.3 MW. After one hour, the export of slag to the electric arc furnace starts, which lasts for 2 hours. Copper content 1.1% and Fe 3 o 4 The slag with a content of 7% is transferred to the DC arc furnace 2 with an ionization chamber through the slag discharge tank 8, which is four meters long and one meter wide. A reducing slagging furnace for semi-continuous slagging is shown in FIG. 2 . The slag flows through the reduction slagging furnace 2 continuously for two hours. When the slag level is one meter, the average residence time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com