Turn signal switch device

A switch device and turn signal technology, applied in signal devices, electric switches, optical signals, etc., can solve the problems of reduced assembly efficiency and increased number of parts, and achieve the goal of improving assembly efficiency, controlling the number of parts, and simplifying assembly operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

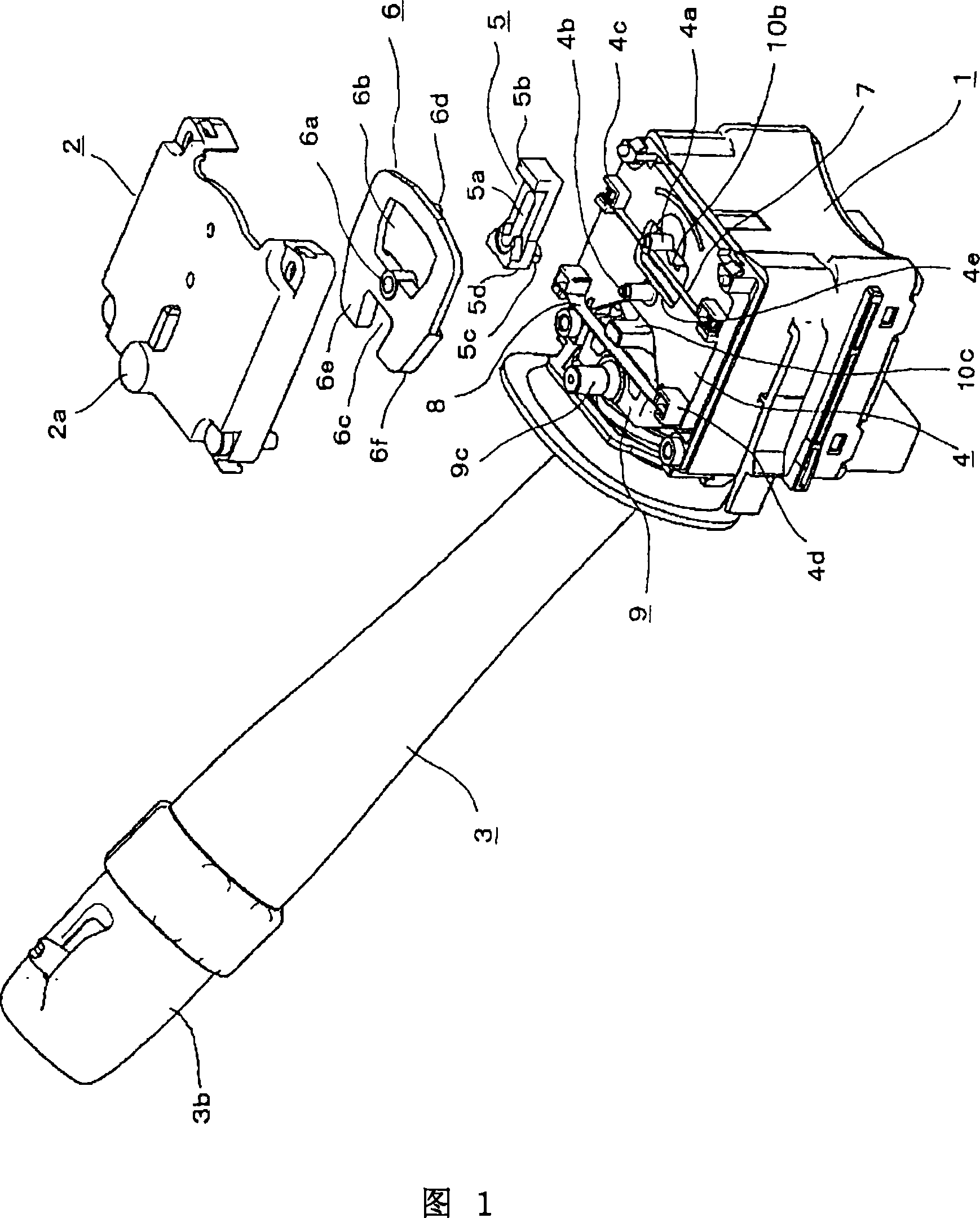

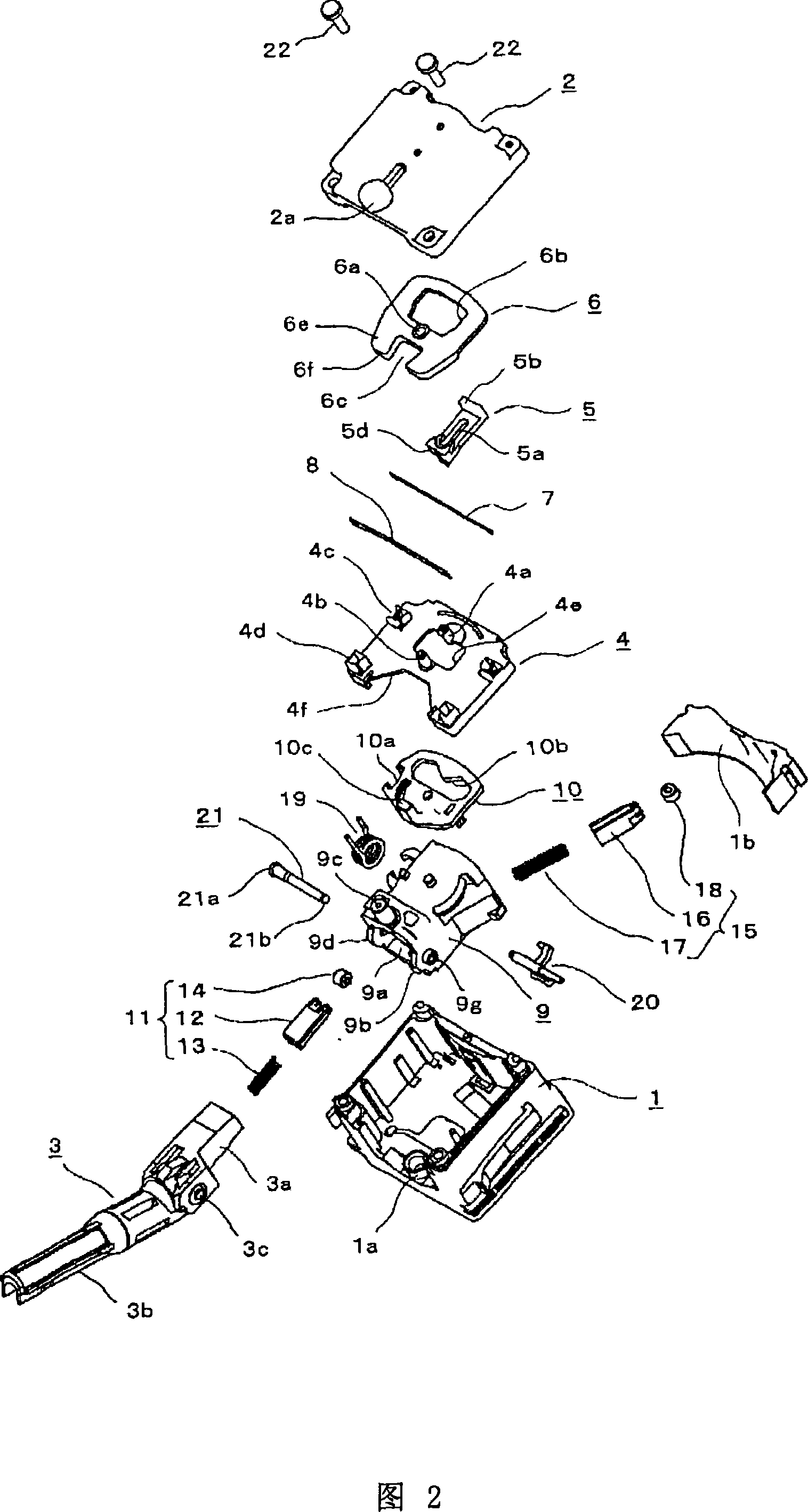

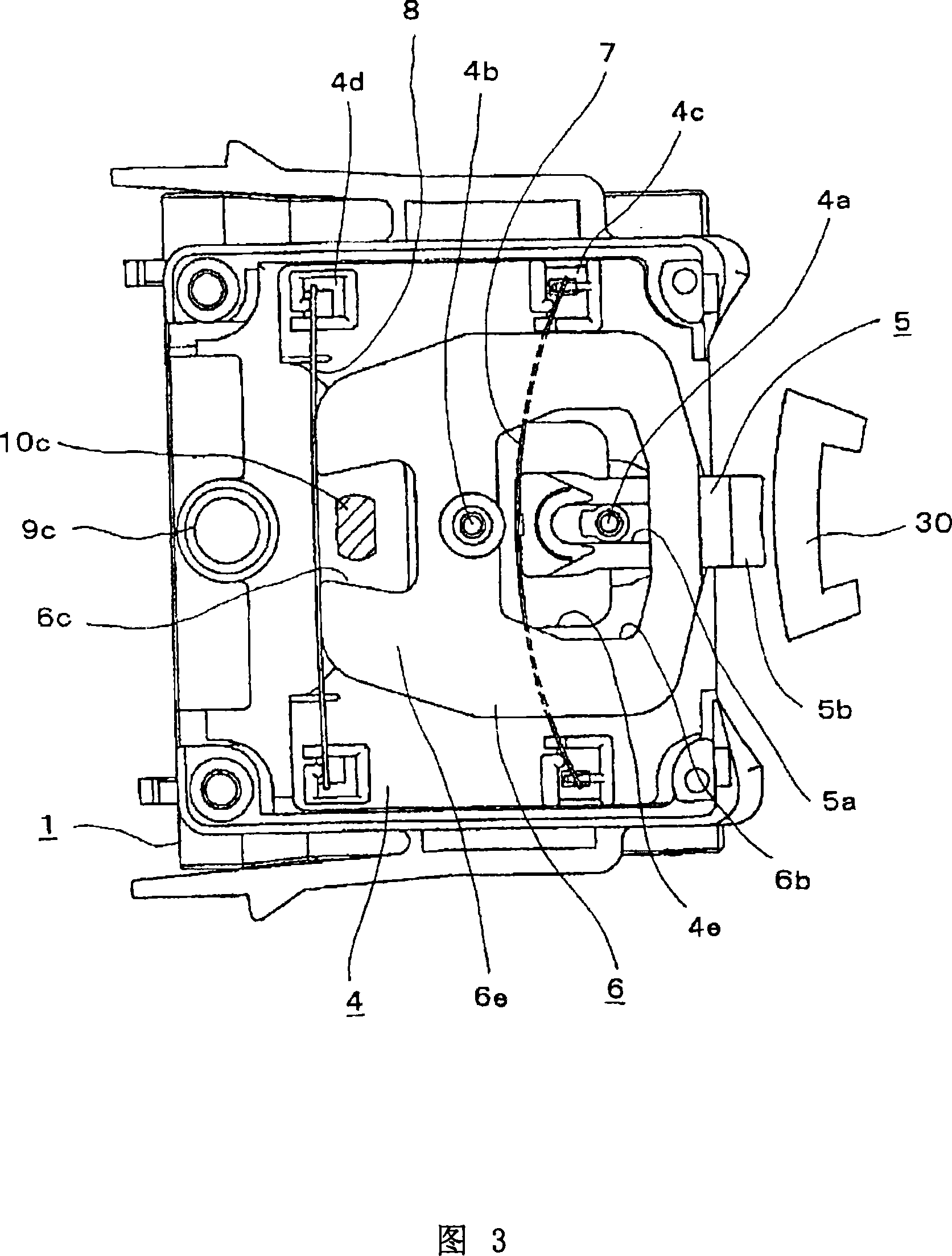

[0057] Hereinafter, specific embodiments of the present invention will be described with reference to the accompanying drawings. FIG. 1 is an external view showing a part of a turn signal switch device according to an embodiment of the present invention, FIG. 2 is an exploded perspective view of the turn signal switch device, and FIG. 3 shows a cancellation mechanism of the turn signal switch device. Fig. 4 is an explanatory diagram showing the state before the operation lever is automatically reset in the cancellation mechanism, and Fig. 5 is an illustration showing the shaft installation for connecting the base of the operation lever on the bracket 6 is an explanatory view showing a state where the installation work of the shaft has been completed, and FIG. 7 is an explanatory view showing a modified example of the bracket shown in FIG. 6 .

[0058] The turn signal switch device shown in these figures mainly includes: the first box part and the second box part forming the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com