Fireproof cable and its making method

A fire-resistant cable and fire-resistant fiber technology, which is applied in the direction of cable/conductor manufacturing, insulating cables, conductor/cable insulation, etc., can solve the problems of low temperature resistance level, production difficulty, thick thickness, etc., and achieve refractoriness and temperature resistance level High, reduce the cost of refractory insulation, safe and reliable signal transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

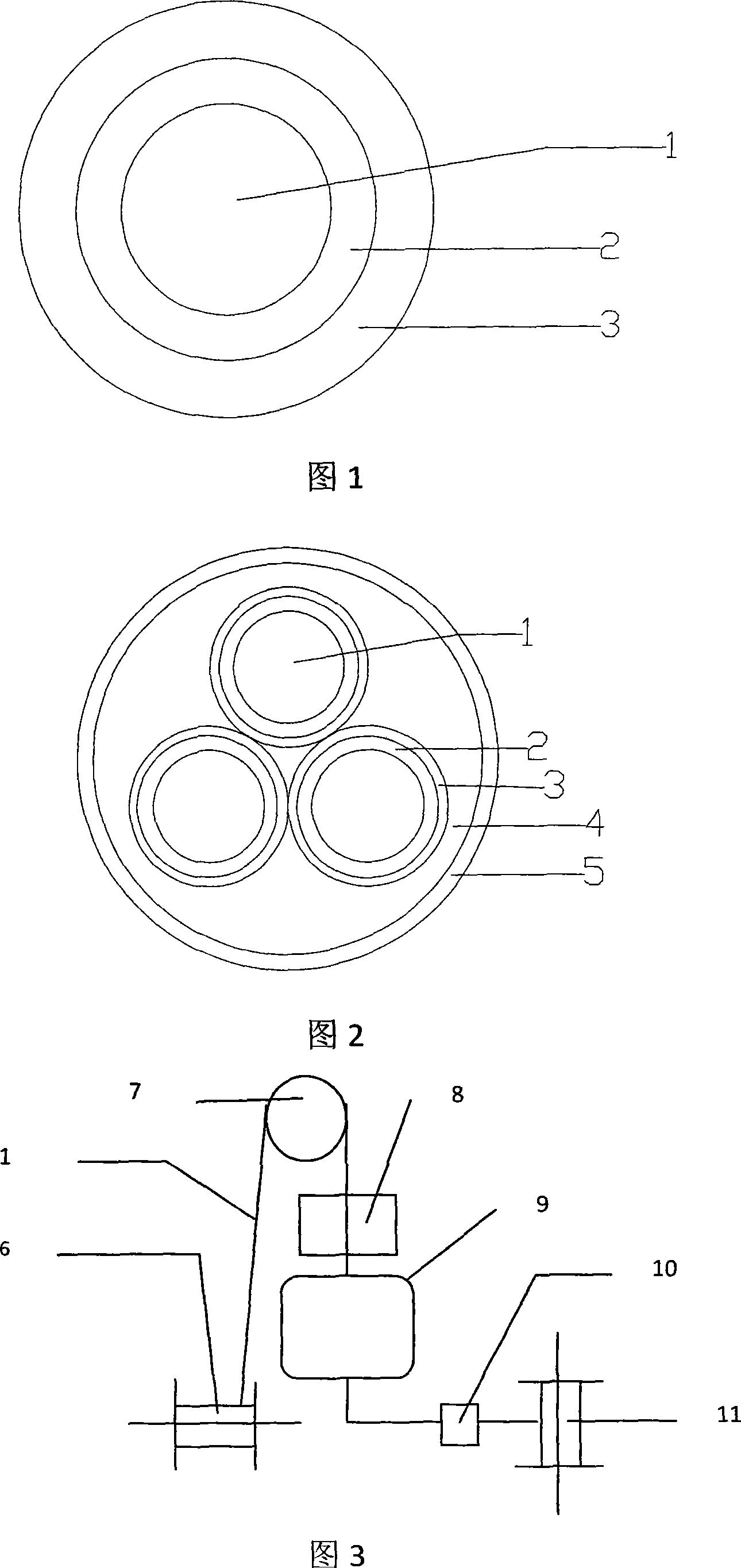

[0026] Embodiment 1: Referring to Fig. 1, the single-core fire-resistant cable of the present invention is successively stranded soft conductor 1 from the inside to the outside, which is composited on the surface of the conductor through high-temperature drawing, and the thickness is 0.08mm silicon dioxide (SiO 2 ) refractory insulating layer 2 (also can be silicon tetrachloride or silicon crystal), with BeiCoTex fiber braided sheath protective sheath 3 outside.

[0027] Preparation: According to the process in Figure 3, the conductor 1 is released from the pay-off reel 6, preheated to 200-600°C by the conductor preheating device 7 (adjusted depending on the conductor wire diameter), and penetrated (before heating) into the prefabricated material made of the above The formed hollow prefabricated tube is heated by the high-temperature furnace 8 to soften the silicon prefabricated tube, and then drawn through a mold to change the diameter (thinned and thinned) and composited on t...

Embodiment 2

[0028] Embodiment 2: Referring to Fig. 2, a three-core fire-resistant cable has three fire-resistant insulated wire cores described in Embodiment 1, which are filled with 4 to form a cable core, tied tightly with cable ties 5, and a refractory fiber braided sheath.

[0029] It may also be that there is only one refractory insulated wire core described in Embodiment 1.

Embodiment 3

[0030]Embodiment 3: as the aforementioned single-core or three-core fire-resistant cable, wherein at least one conductor 1 and the outer silicon refractory insulating layer 2 are a three-layer composite structure with a thickness of 1.0mm, the inner and outer layers are silicon tetrachloride, and the middle layer is two Silicon oxide, which constitutes a fire-resistant power cable with optical communication.

[0031] Preparation: The preparation method is as described in Example 1, in which the composite refractory insulating layer of the pultrusion package is first made of three types of hollow tubes, the inner, the middle, and the outer, respectively, according to the outer diameter of the sleeve, and the middle silicon tube is heated to above 300 ° C, so that After expansion, put it on the inner glass tube, cool to make the two tightly combined; then heat the outer silicon tube to above 300°C to make it expand, set it on the two layers of silicon tubes that have been prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com