Polarization maintaining fiber beat length measuring apparatus

A polarization-maintaining optical fiber and measuring instrument technology, applied in the direction of measuring devices, optical instrument testing, instruments, etc., can solve the problems of complex structure, easy damage of optical fiber, and non-negligible impact, so as to simplify the composition structure, expand the application range, reduce The effect of design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

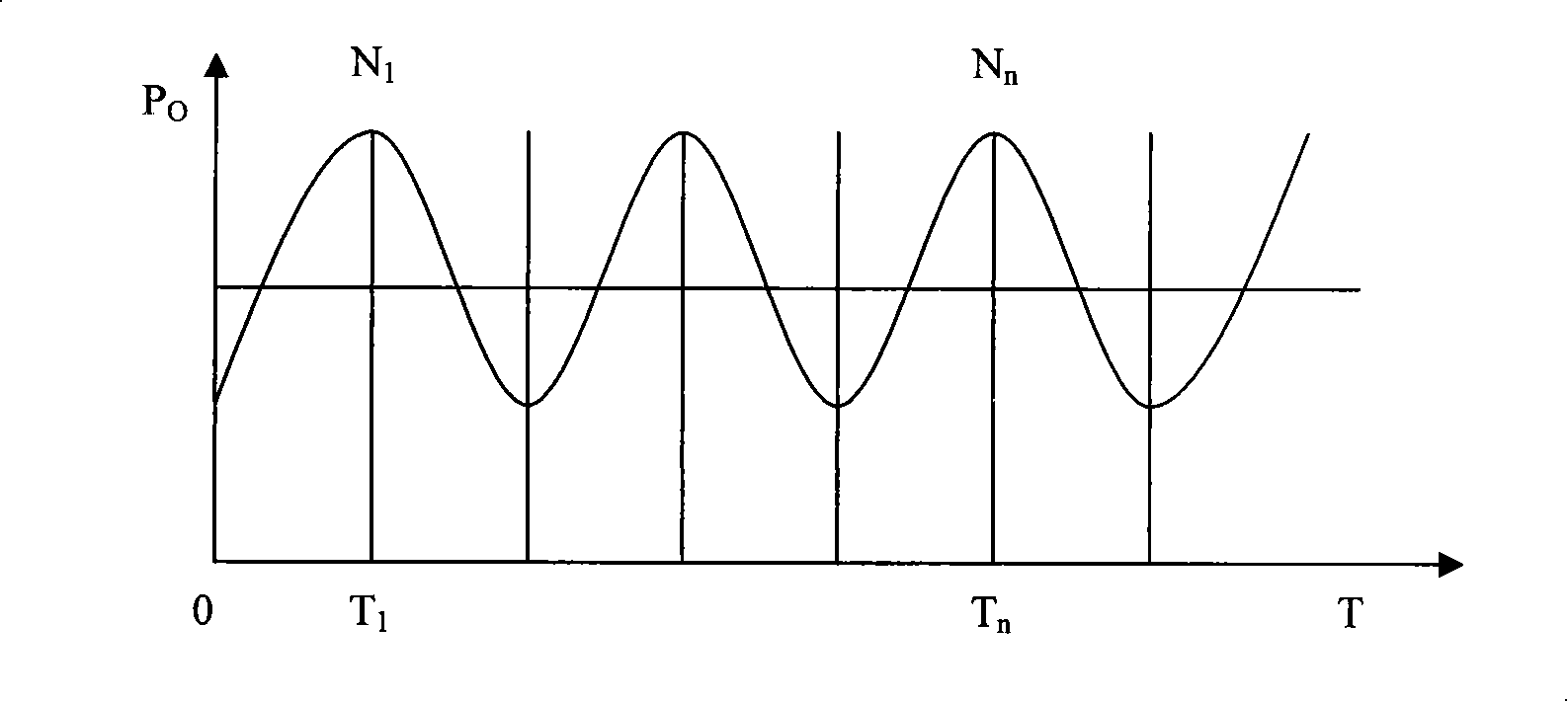

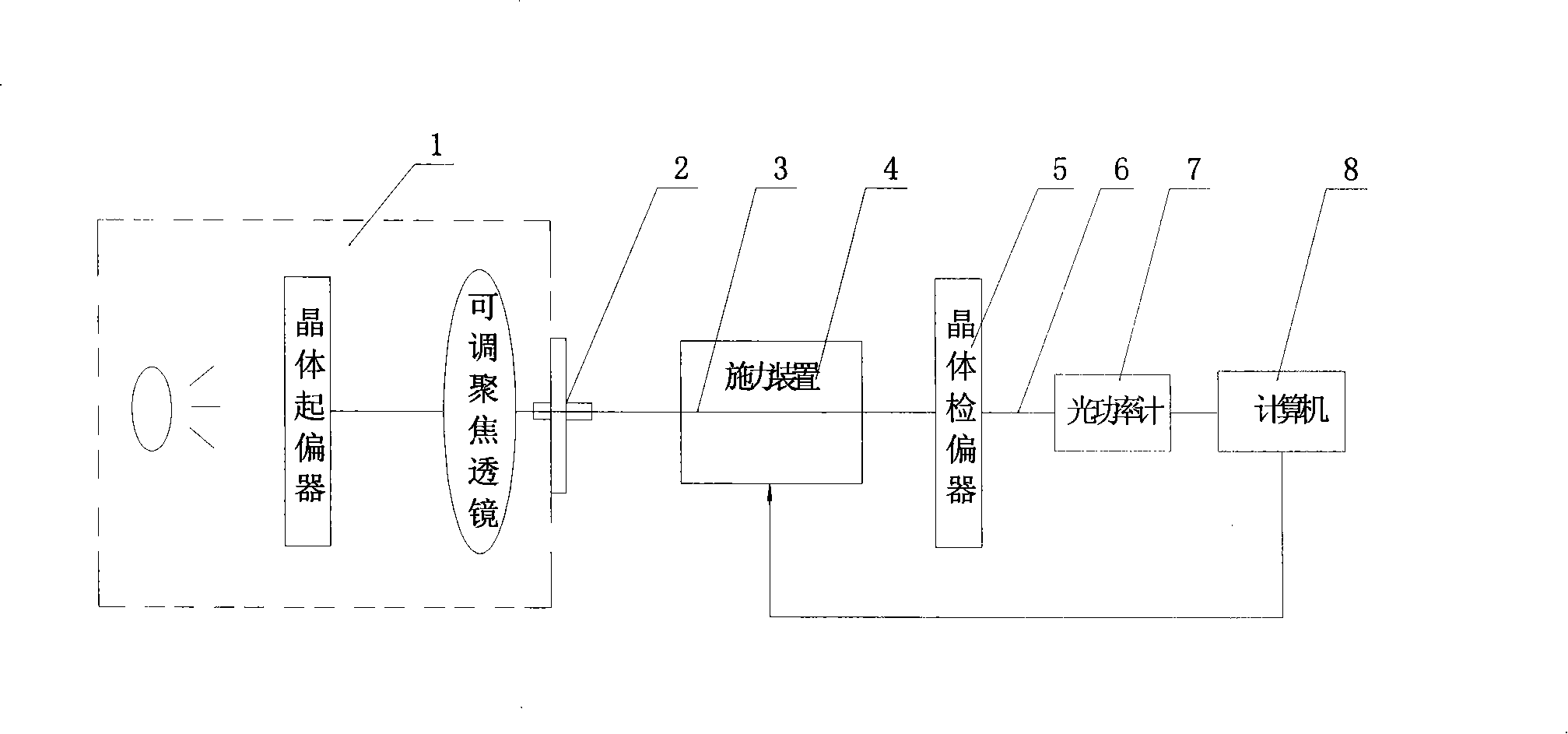

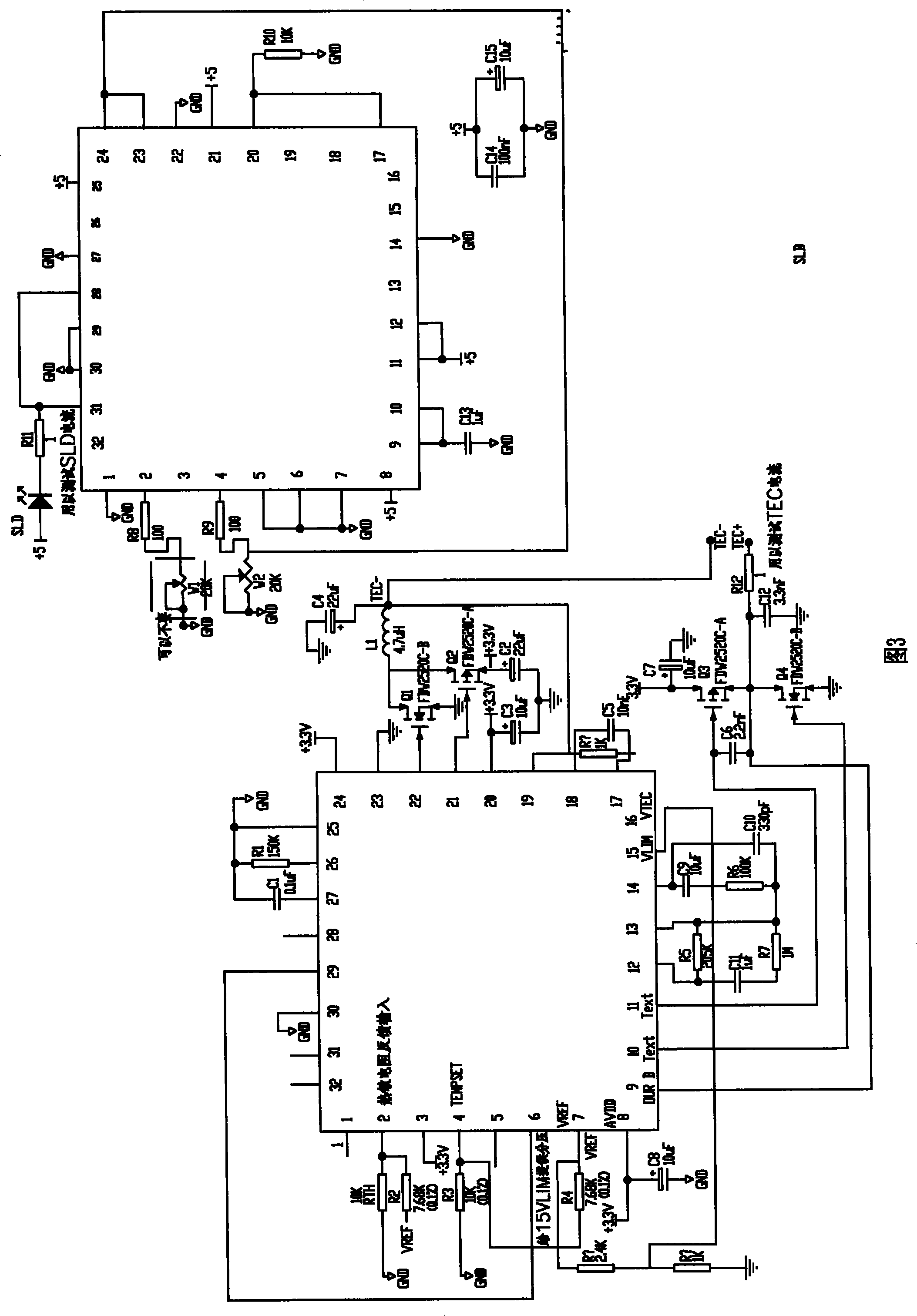

[0023] as figure 2 As shown, the preferred embodiment of the present invention includes an optical path system, a force applying device 4, and a data acquisition and processing system. The optical path system includes a light source, a crystal polarizer, a focusing lens, and a crystal analyzer. The light source, crystal polarizer, and focusing lens are individually integrated into an extinction ratio test device. The light source is composed of a semiconductor laser and a light source drive circuit. Through experimental analysis, it is found that the fluctuation of optical power is mainly determined by the ambient temperature and the constant current source. When the ambient temperature is within the refrigeration control range, the constant current source plays a major role. When the ambient temperature changes greatly, the latter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com