Ball-valve manufacture method

A manufacturing method and ball valve technology, applied in the field of ball valve manufacturing, can solve problems affecting industrial competitiveness, heavy overall quality, waste of water resources, etc., and achieve the effects of convenient production, sales, assembly and use, difficult chemical changes, and price increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

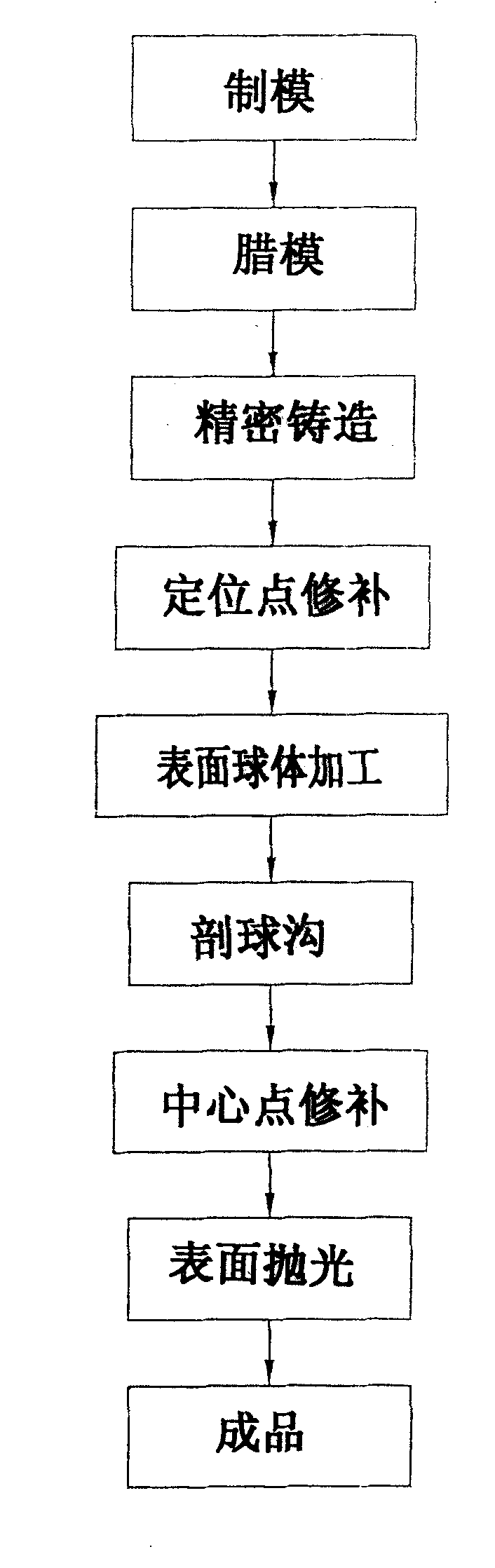

[0046] The present invention relates to a manufacturing method of a ball valve, please refer to Figure 1 to Figure 10 As shown, the manufacturing method of this ball valve mainly includes the following steps:

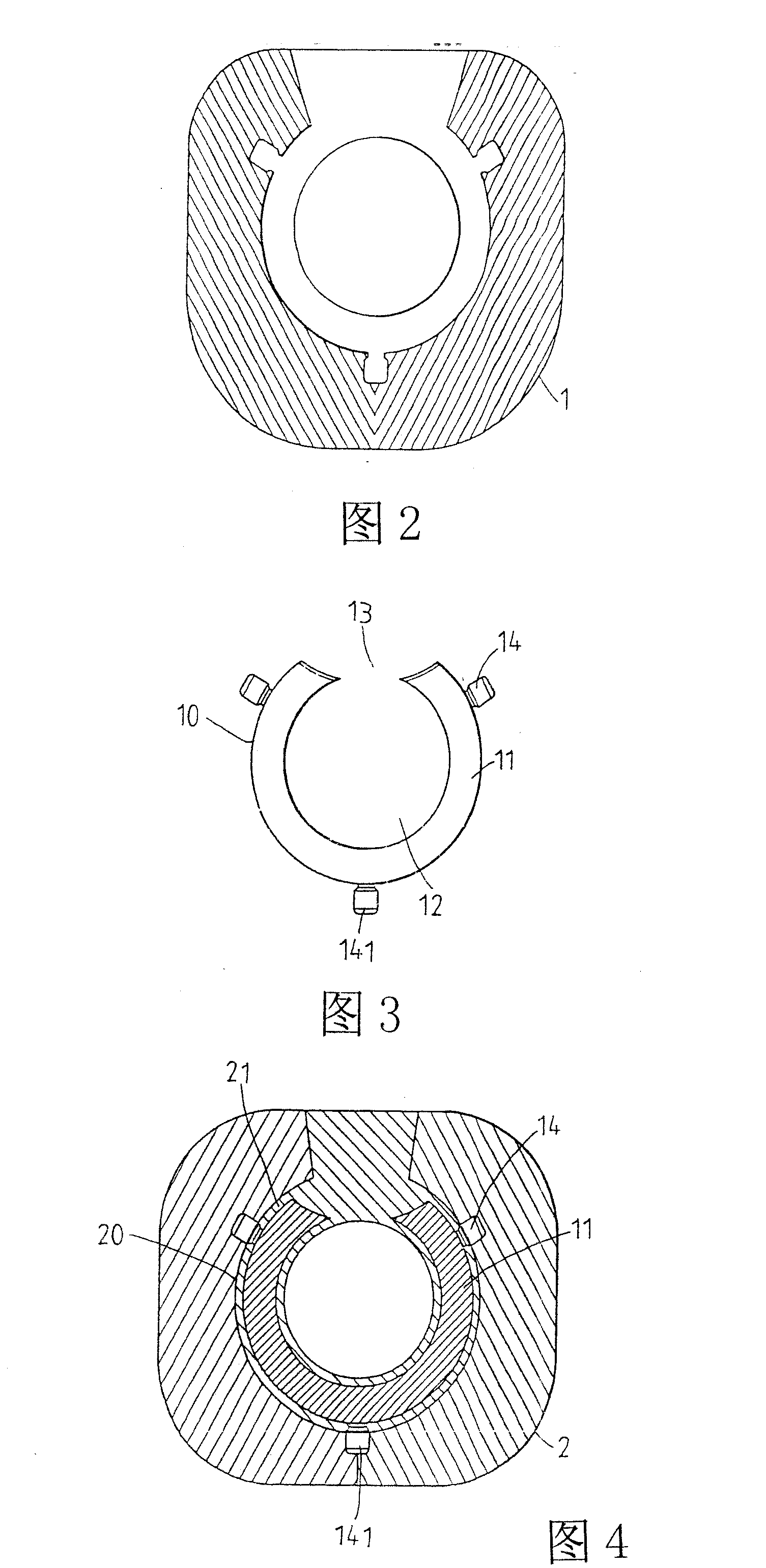

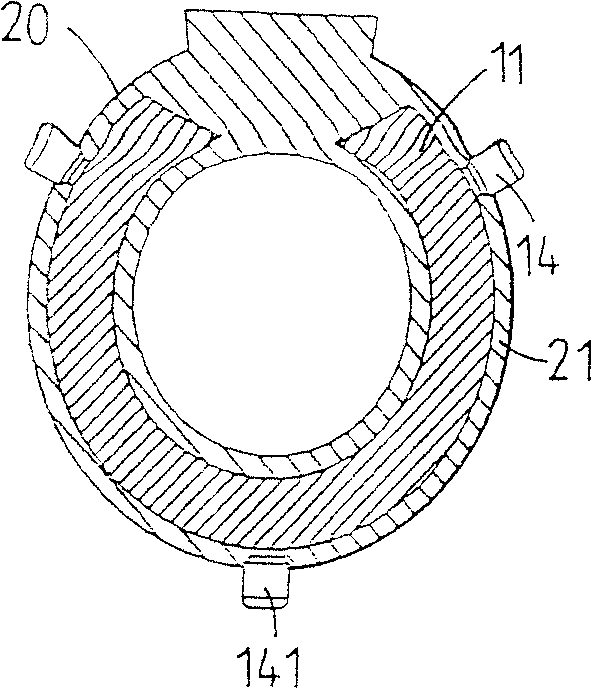

[0047] Modeling: such as figure 2 As shown, the first mold 1 of the corresponding size is selected according to the size of the ball valve to be manufactured, and then the raw materials whose main components are fire-resistant and heat-resistant materials such as magnesium oxide and aluminum oxide are poured into the first mold 1, and the mold is made as shown in FIG. image 3 The first base body 10 shown, the first base body 10 includes an arc-shaped inner filler 11, the inner filler 11 has a through hole 12 in the center, and the two ends of the inner filler 11 are separated by an opening 13 The outer side of the filling 11 is protrudingly provided with several positioning points 14 , at least one positioning point 14 is located on the axis of line symmetry of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com