Double cylinder wind cooling diesel

A diesel engine, air-cooled technology, applied in the direction of cylinder, cylinder head, mechanical equipment, etc., can solve the problems of small joint area of annular groove or spiral groove, failure of lubricating parts, reduction of oil viscosity, etc., to solve the problem of aluminum liquid flow and heat dissipation. The effect of improved conditions and increased bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

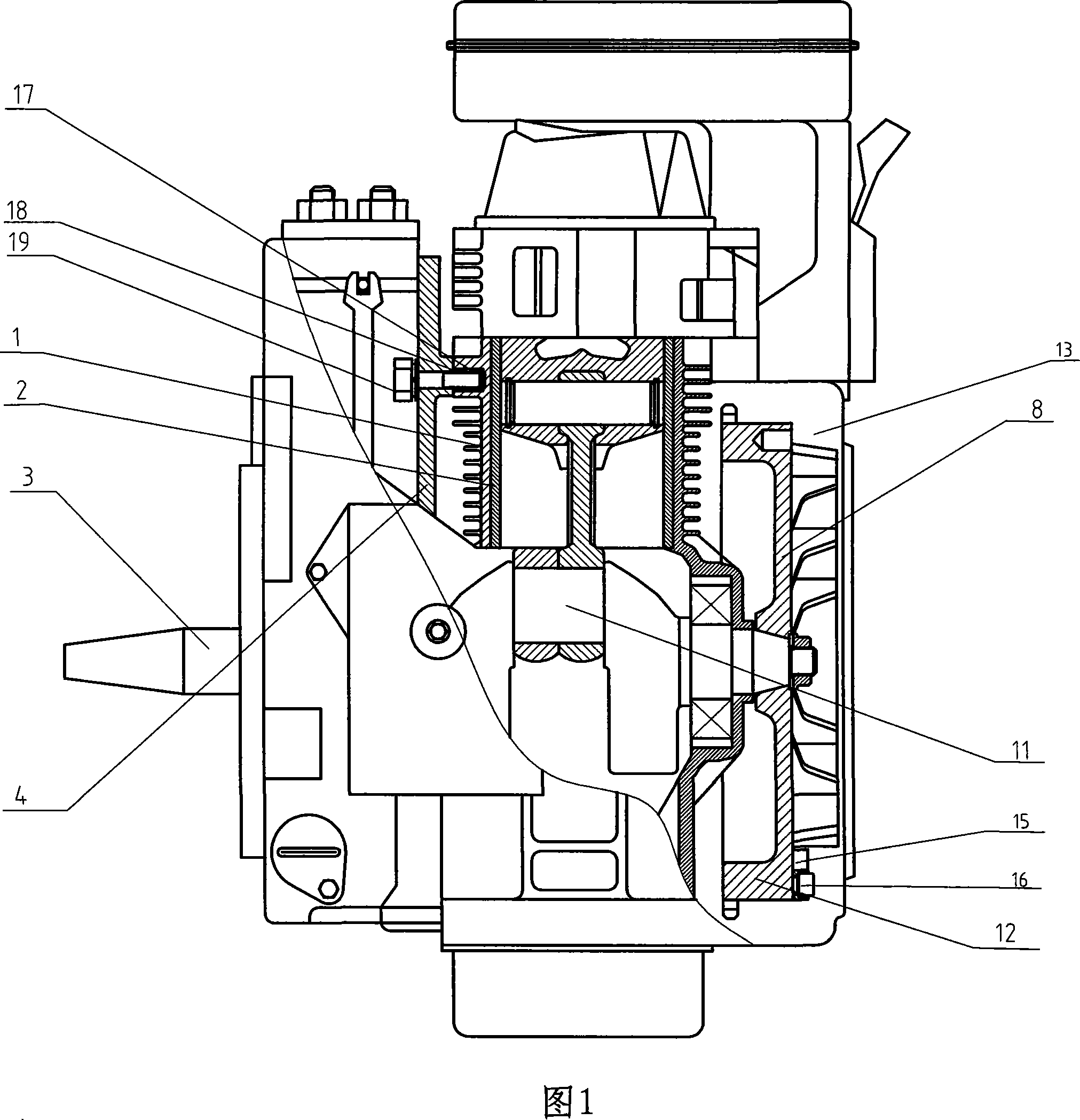

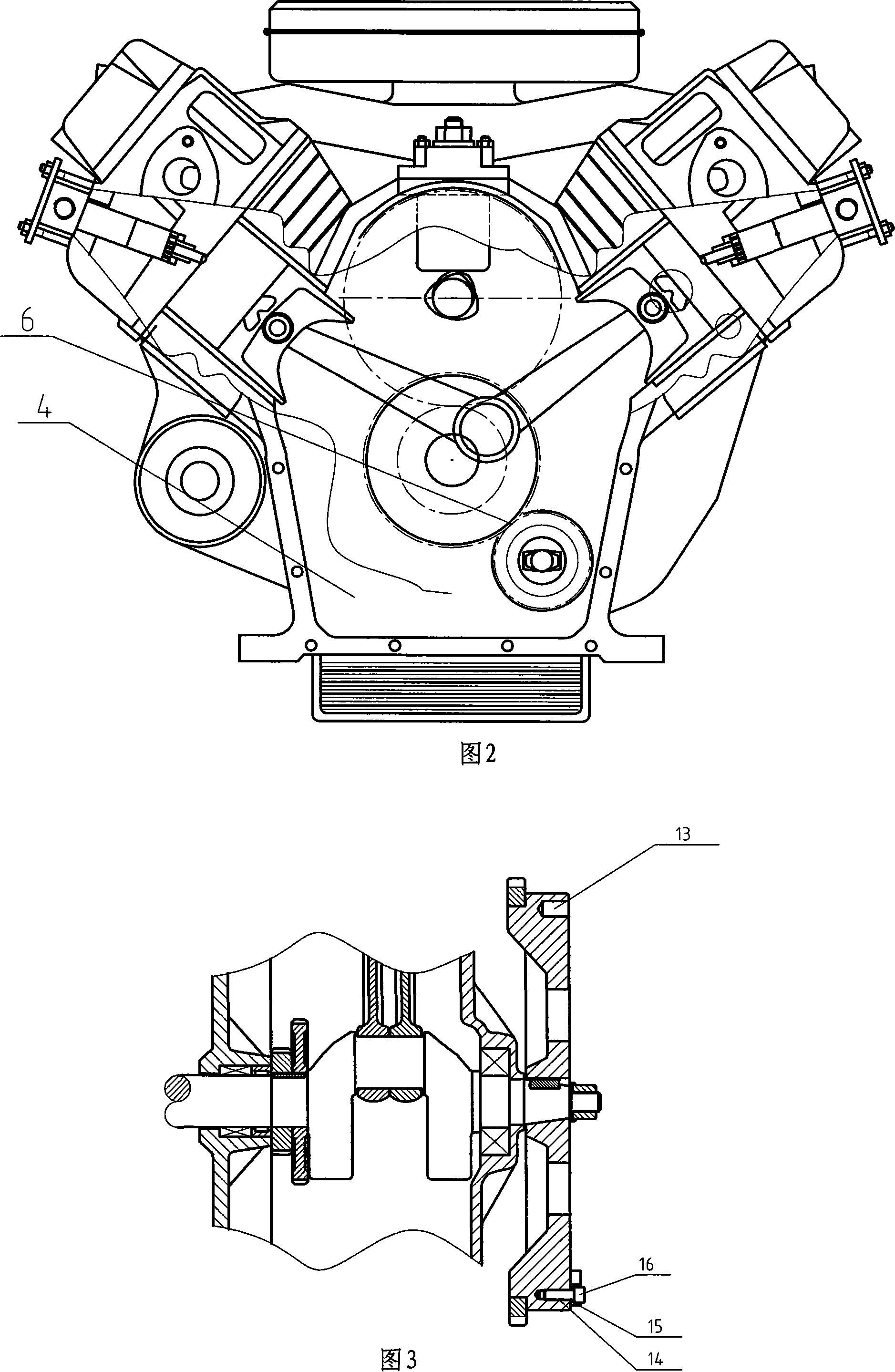

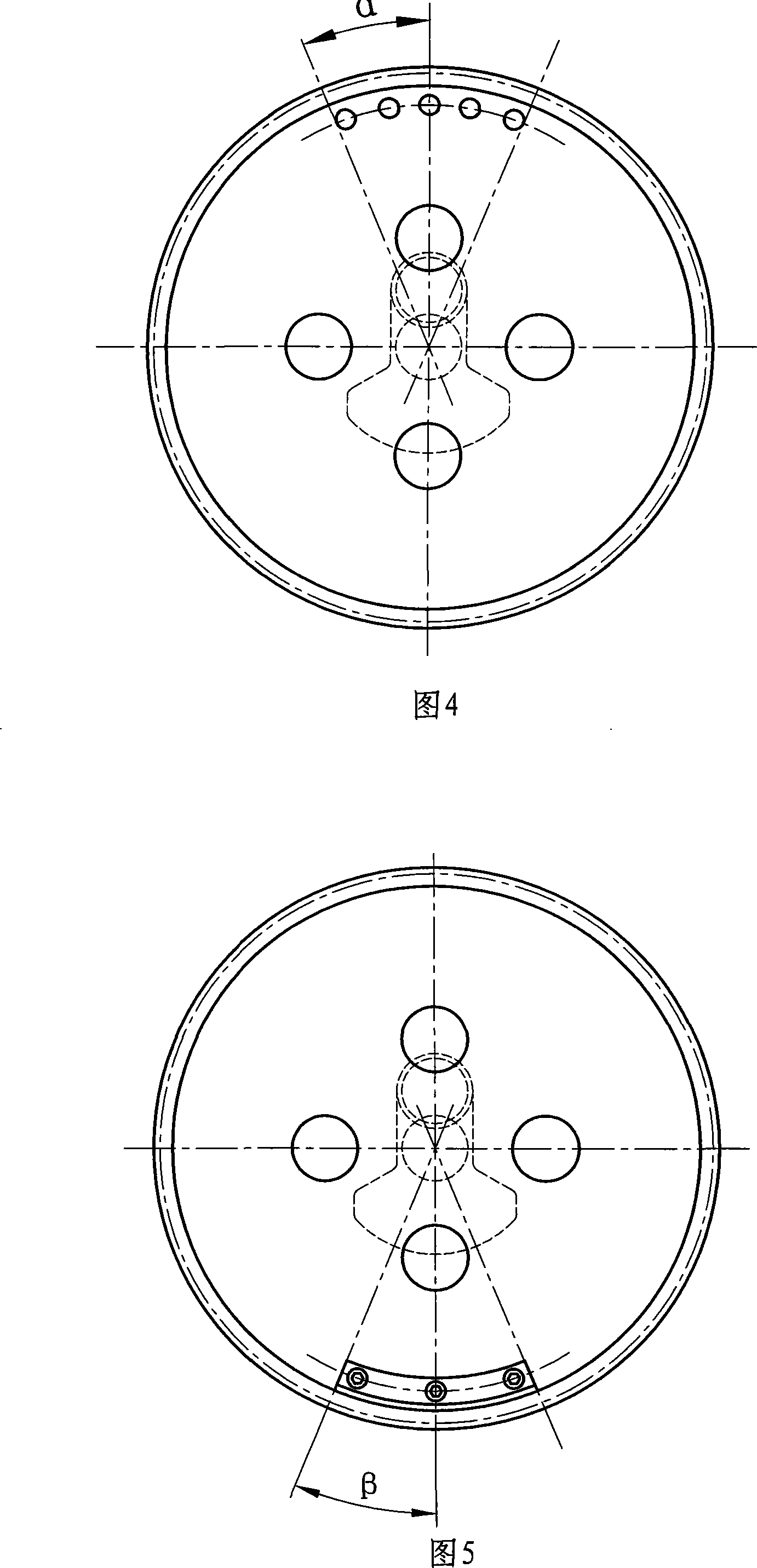

[0037]As shown in Figures 1, 2, 3, 4, 6, 7, 8, 9 and 10, a two-cylinder air-cooled diesel engine includes a body 1, a cylinder liner 2, a crankshaft 3, a crankcase cover 4, an oil pump 5, and an oil pump The transmission gear 6, the flyweight 7 and the flywheel 8, the two ends of the crankshaft 3 are installed on the body 1 and the crankcase cover 4 respectively, the two flyweights 7 are symmetrically arranged on the speed governor transmission gear 9, and the crankcase cover 4 is provided with There is a high-pressure oil passage 10, and the flywheel 8 is located at one end of the crankshaft 3 connected to the body 1. The flywheel 8 is provided with 5 balance deduplication holes 13 on the upper part of the hub 12 corresponding to the direction of the crankshaft 11, and the balance deduplication holes 13 are evenly distributed on the circumference of the hub. , and its setting range is the left and right symmetrical deflection angle α=17.5° of the vertical line of the hub. A s...

Embodiment 2

[0039] As shown in Figures 1, 2 and 5, a two-cylinder air-cooled diesel engine includes a body 1, a cylinder liner 2, a crankshaft 3, a crankcase cover 4, an oil pump 5, an oil pump transmission gear 6, a flyweight 7 and a flywheel 8, and the crankshaft The two ends of 3 are respectively installed on the body 1 and the crankcase cover 4, and the two flyweights 7 are arranged symmetrically on the governor transmission gear 9, the crankcase cover 4 is provided with a high-pressure oil passage 10, and the flywheel 8 is provided on the crankshaft 3 One end of the connecting body 1 is provided with a balance weight mounting hole 14 at the hub 12 bottom of the flywheel 8 corresponding to the direction of the crank throw 11, and the balance weight 15 is fixed in the balance weight mounting hole 14 by bolts 16. The balance weight mounting holes 14 are evenly distributed on the circumference of the wheel hub 12, and the setting range is left and right symmetrical deflection angle β=17.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com