Carving head with feed motion

A technology of feed movement and engraving head, which is applied in the field of engraving, can solve the problems of increasing the center height of the machine tool support column, increasing the center height of the engraving head, and increasing the manufacturing cost of the machine tool, so as to reduce the center distance and solve the problem of large volume , The effect of difficult knife setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

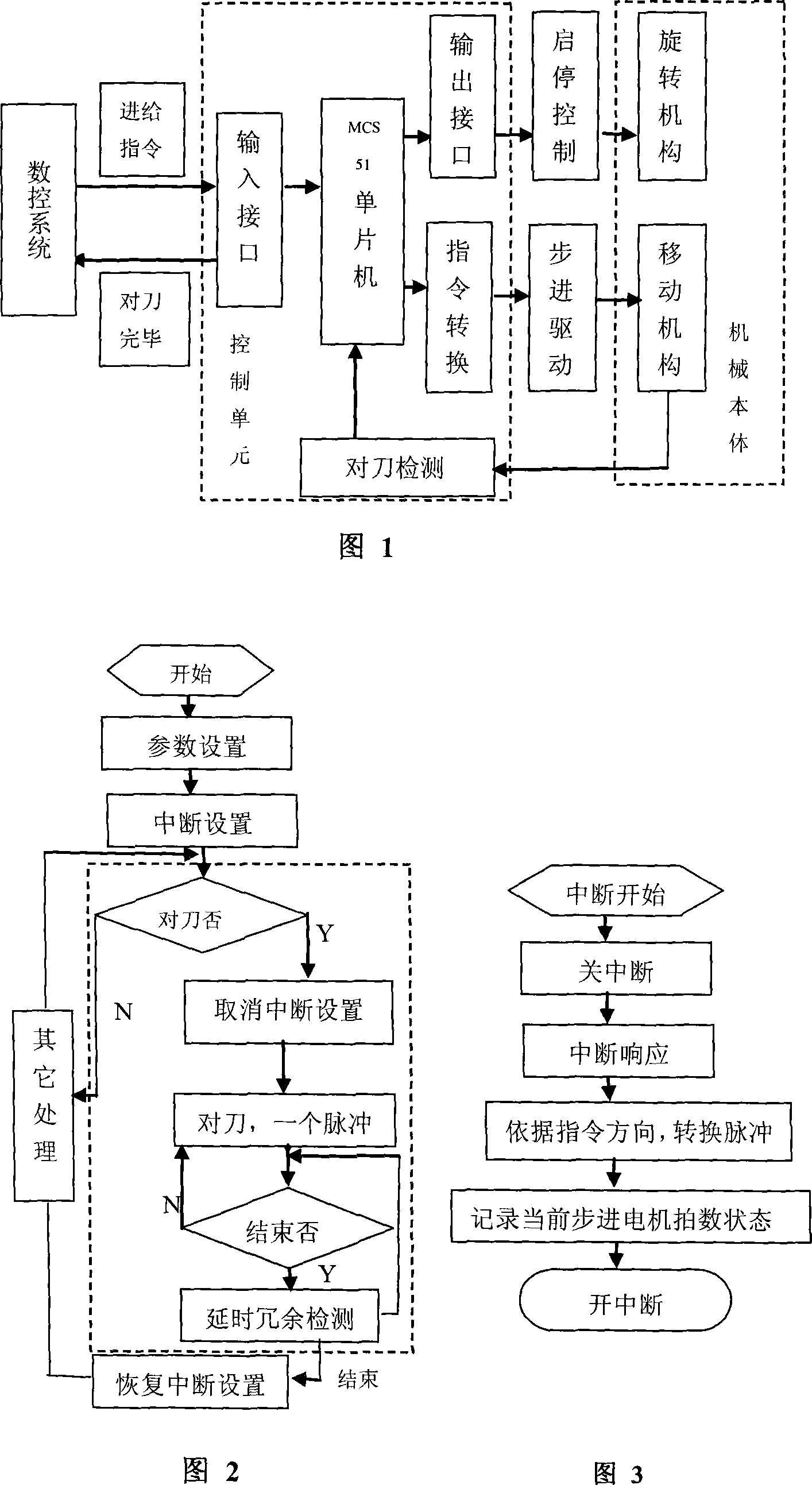

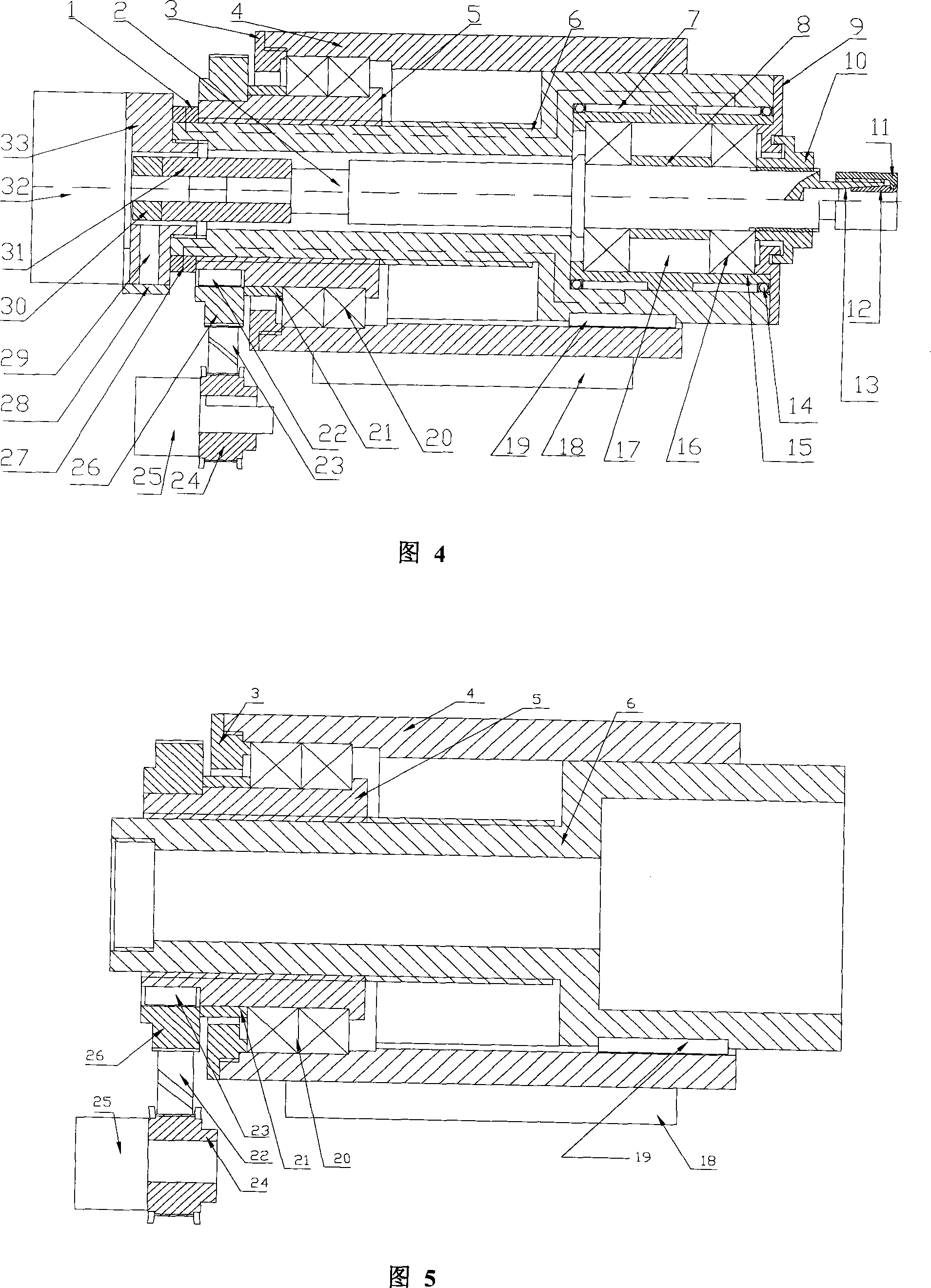

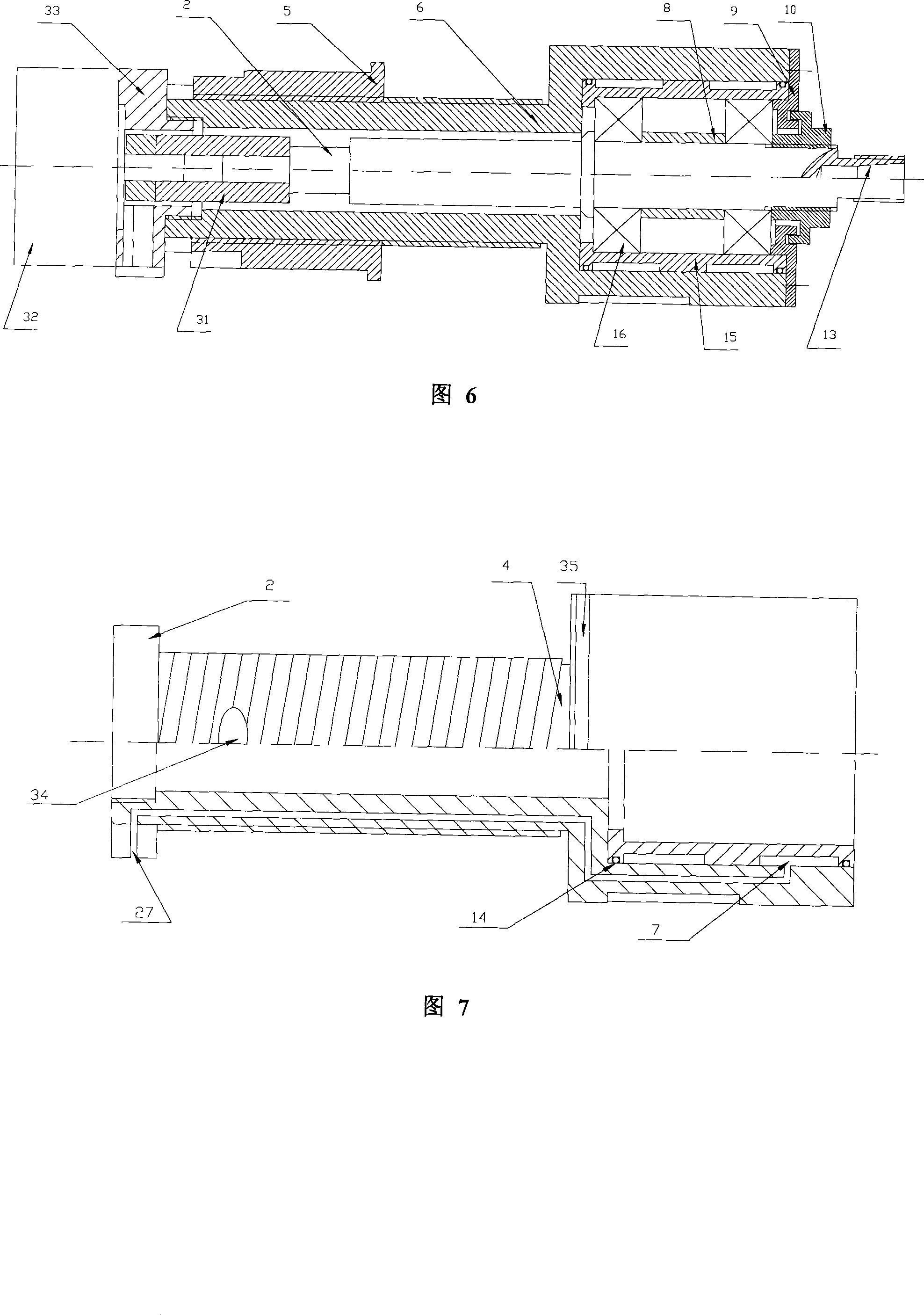

[0022] The engraving head with feed movement provided by the present invention is composed of an engraving head control system and an execution mechanical system (see Fig. 1 to Fig. 7). Among them: the engraving head control system is composed of MCS51 single-chip microcomputer system that relies on electrical contact for tool setting function. The input interface of the single-chip microcomputer accepts the standard numerical control command signal of "differential mode command + pulse" issued by the numerical control system, and is processed by the single-chip microcomputer. It is transformed into the "three-phase six-beat" special control signal of the stepping motor, and then output to the driver of the stepping motor through the command conversion interface to realize the feed motion control of the engraving head. During the tool setting process, the single-chip microcomputer system continuously monitors the electrical contact signal of the tool setting detection interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com