Force-bearing type superposed component for concrete building lid

A superimposed component, load-bearing technology, applied in the direction of structural elements, building components, floors, etc., can solve the problems of poor integrity, high cost, low shear resistance of the superimposed interface, and achieve the effect of good symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

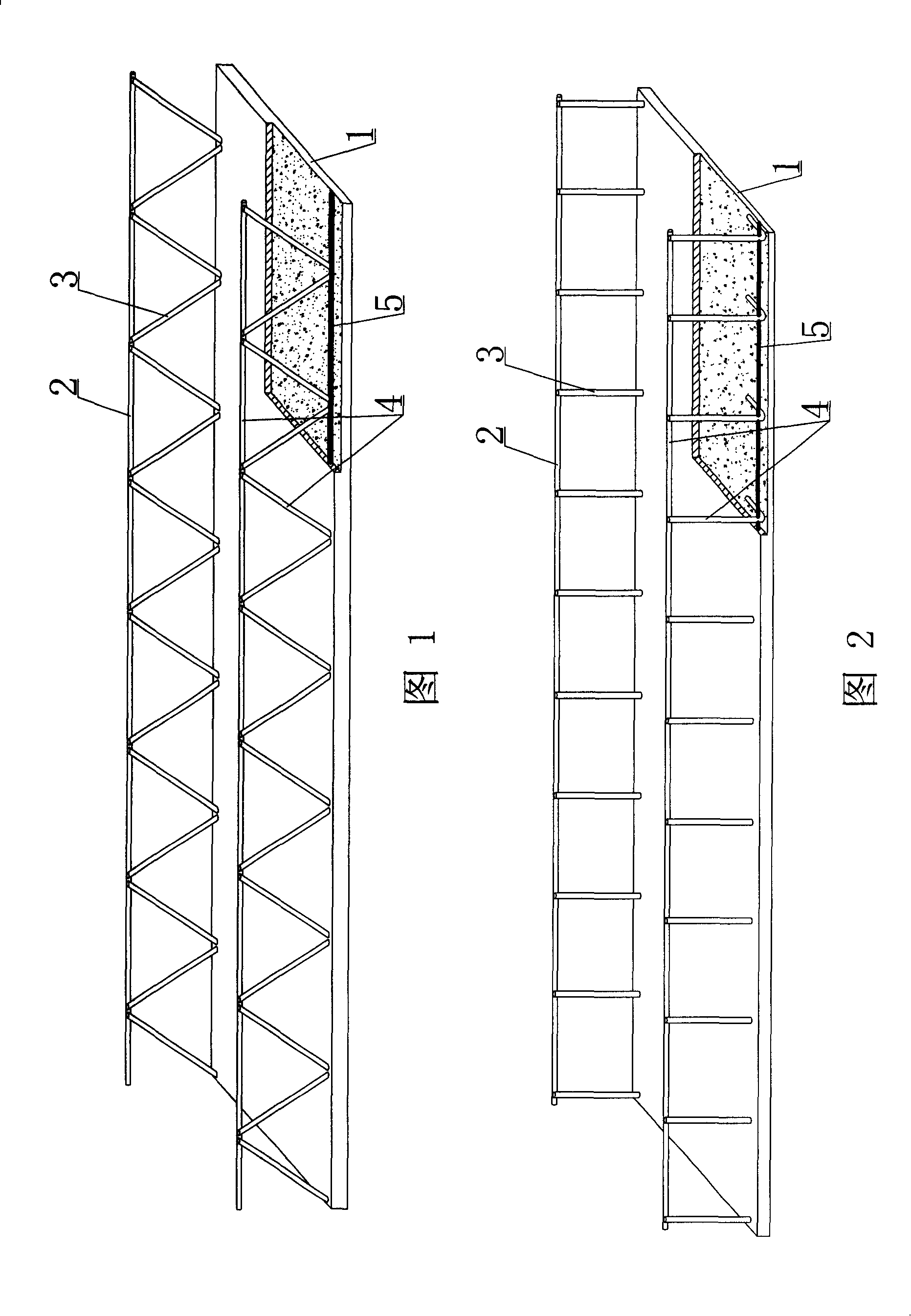

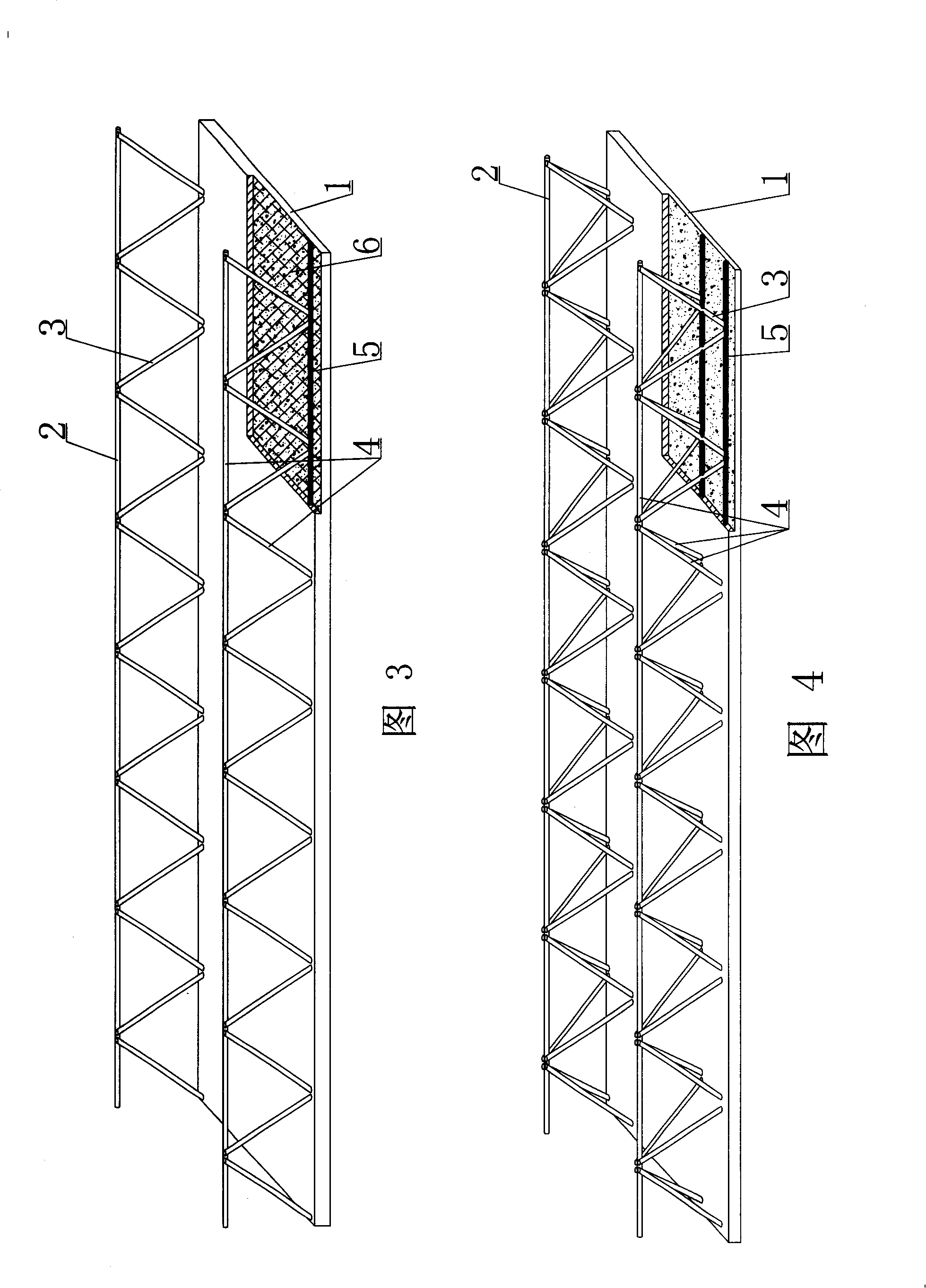

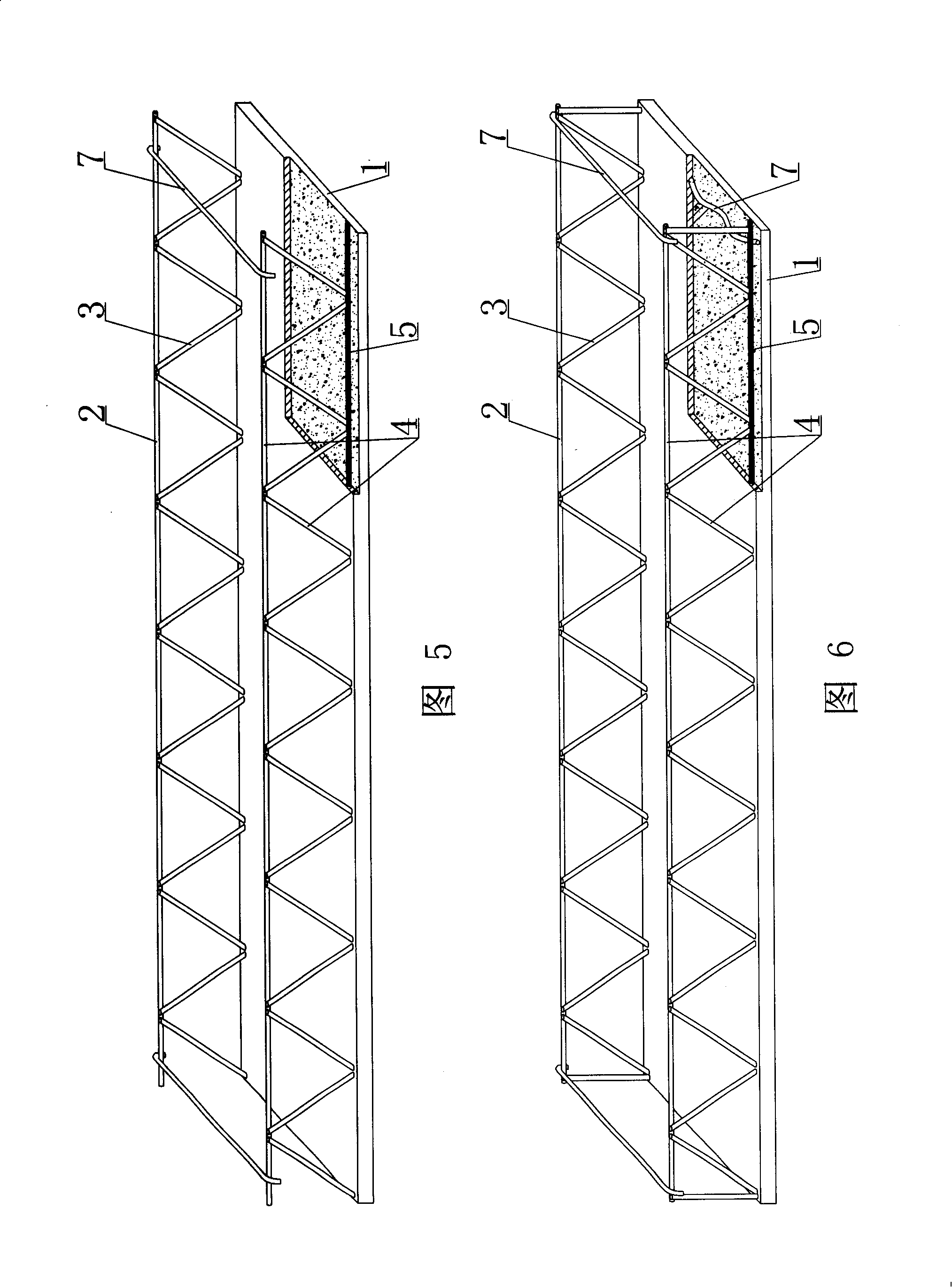

[0053] As shown in the drawings, the present invention includes a bottom plate 1, which is characterized in that it also includes an upper chord 2 and a web 3, and the upper chord 2 and the bottom plate 1 are connected as a whole by the web 3 to form a space load-bearing member of the bar-plate truss 4 , there is at least one steel bar 5 parallel to the upper chord 2 in the bottom plate 1, and the web bar 3 is connected with the steel bar 5 as a whole. In each accompanying drawing, 1 is the bottom plate, 2 is the upper chord, 3 is the web, 4 is the rod-plate truss, and 5 is the steel bar. In the following drawings, those with the same number have the same description. As shown in FIG. 1 , there is a steel bar 5 parallel to the upper chord 2 inside the bottom plate 1 , and the web bar 3 is connected with the steel bar 5 as a whole.

[0054] The present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com