High-insulation ETFE film structure

An ETFE film, high thermal insulation technology, applied in thermal insulation, building components, building structure and other directions, can solve the problems of poor thermal insulation capacity and difficulty in inflating multiple cavities, so as to solve the problem of poor thermal insulation capacity, ensure exterior decoration modeling, production and Easy to install effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

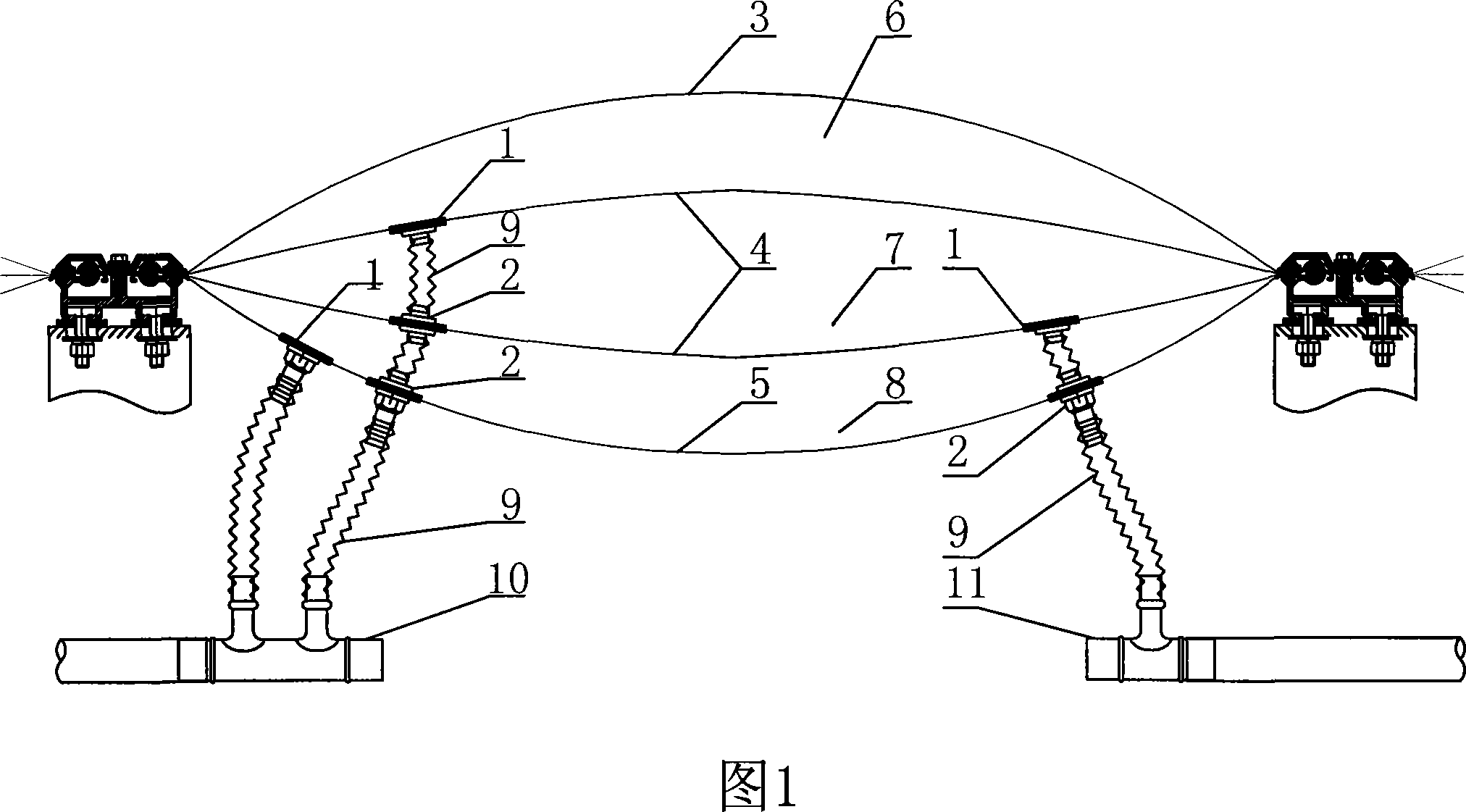

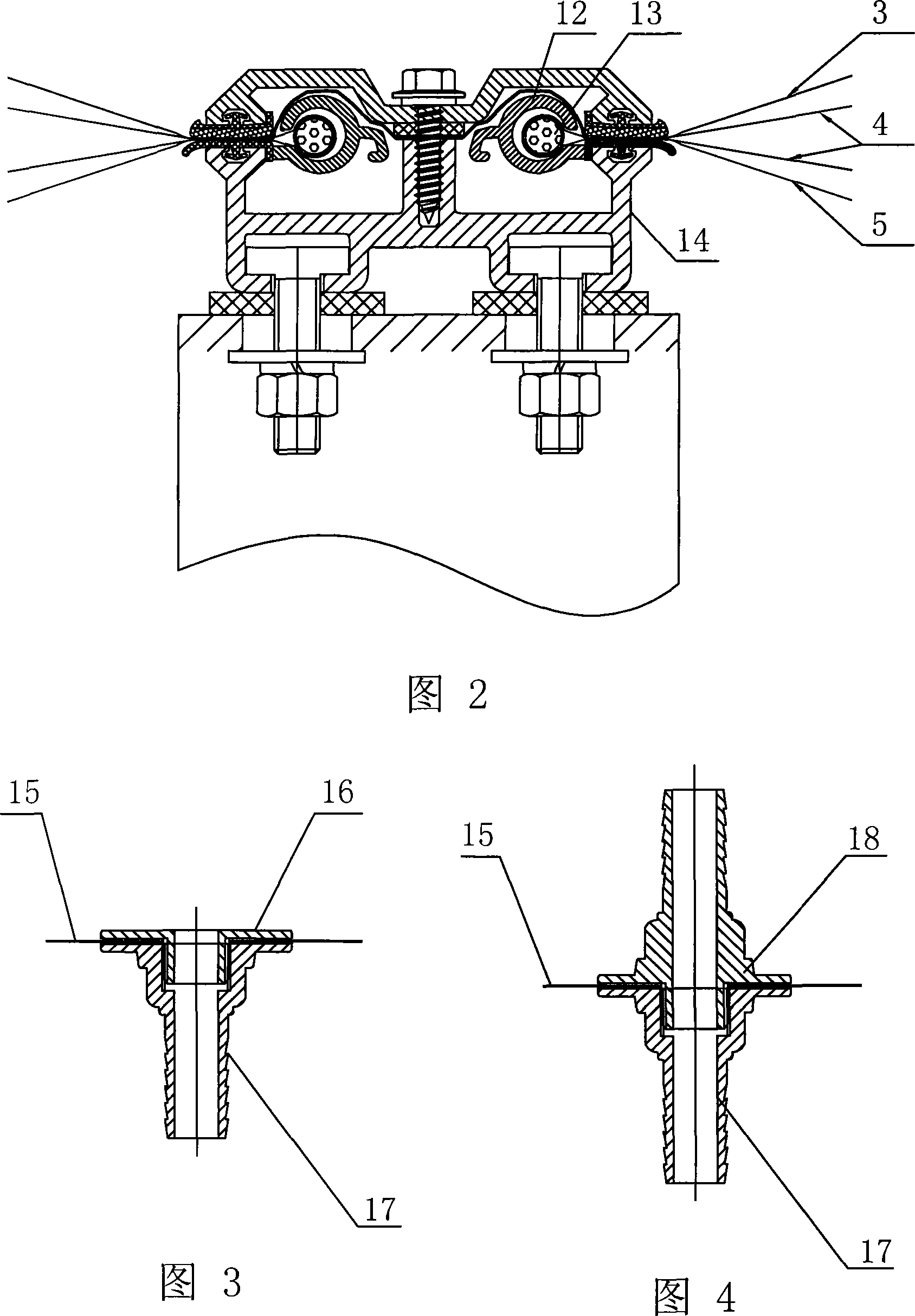

[0014] The present invention will be further described in detail based on Figures 1-4. The high thermal insulation type ETFE membrane structure includes an ETFE membrane layer 15 with a traction cable 13 fixed on the periphery, a metal profile clamp 12 assembled in a cavity formed by a metal profile member 14 and clamps the traction cable 13, an inflatable cavity and its inflation system. The structure of the metal profile fixture 12 and the metal profile member 14 adopts the special metal profile fixture and the special metal profile member and their connection structure in the "film curtain wall structure" (see Chinese Patent Application 200810010045.1) designed by the applicant independently. Among them, each layer of the ETFE film layer is shown in Figure 1, and at least two air-filled cavities can be formed.

[0015] In this embodiment, the ETFE film layer with the traction cord 13 fixed on the periphery is composed of an outer layer film 3, an intermediate layer film 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com