Moving device

A motion device and fluid technology, applied in the field of atmospheric aircraft, can solve problems such as difficult operation and control, complex structure, and unimproved airflow resistance of the fuselage and wings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

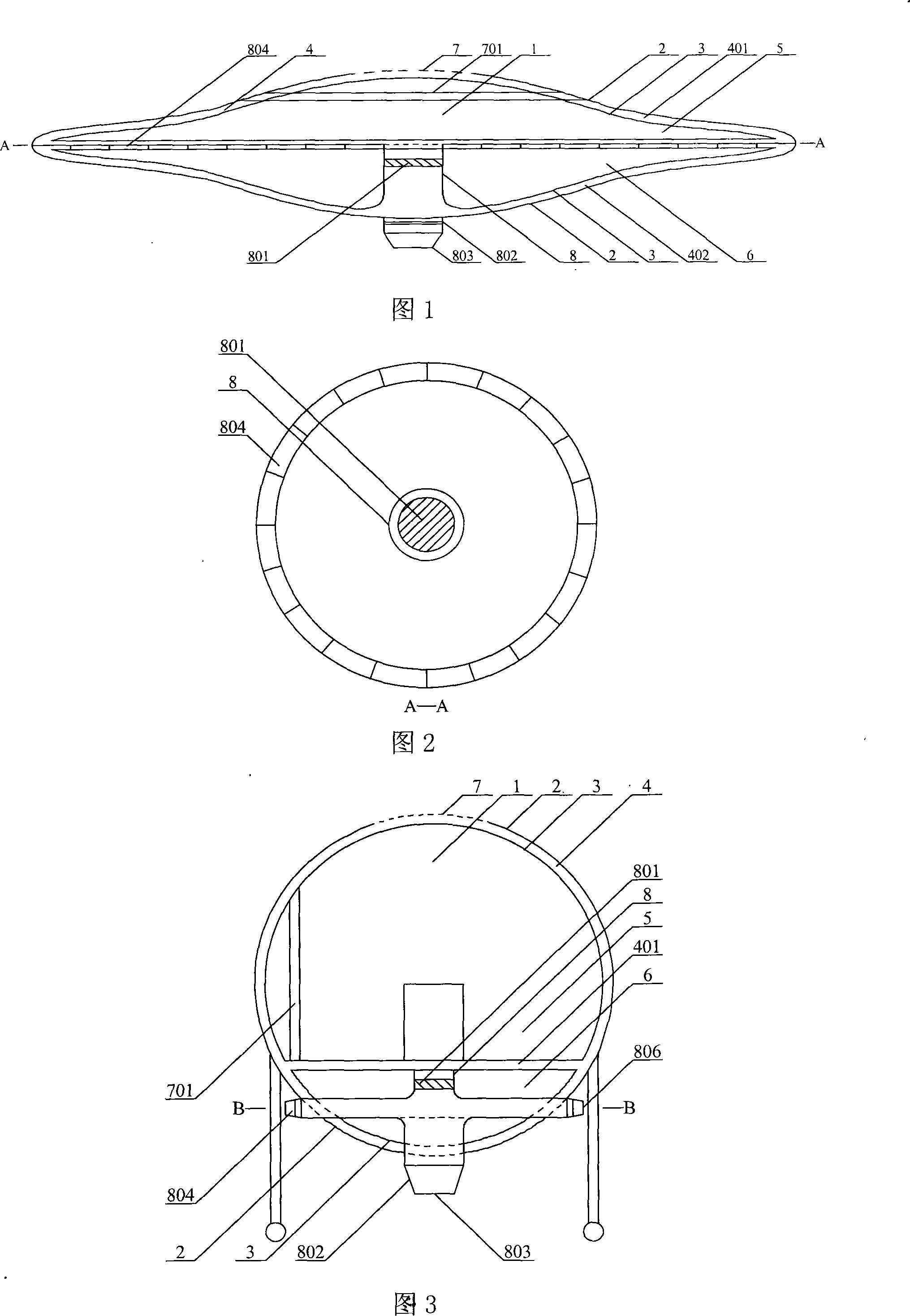

[0055] A kind of flying saucer, as shown in Figure 1 and Figure 2, the overall shape of the flying saucer body 1 is a flying saucer shape, the outer layer of the shell includes an outer shell 2 and an inner shell 3, and there is a certain distance between the inner shell 3 and the outer shell 2. Internal fluid passage 4.

[0056] The internal fluid passage 4 has a fluid suction port, which is opened on the first side, and includes a forward suction port 7 and a side suction port 701 . The forward suction port 7 is located on the top surface of the flying saucer; the lateral suction port 701 comprises a plurality of openings on the upper casing 2, and the first flow regulator is provided in the side suction port 701, and the first flow regulator is similar to The annular window of the louver can communicate the external fluid space with the internal fluid passage 4, and its air intake angle can be adjusted. The side suction port 701 can be a closed ring around the casing, or a...

Embodiment 2

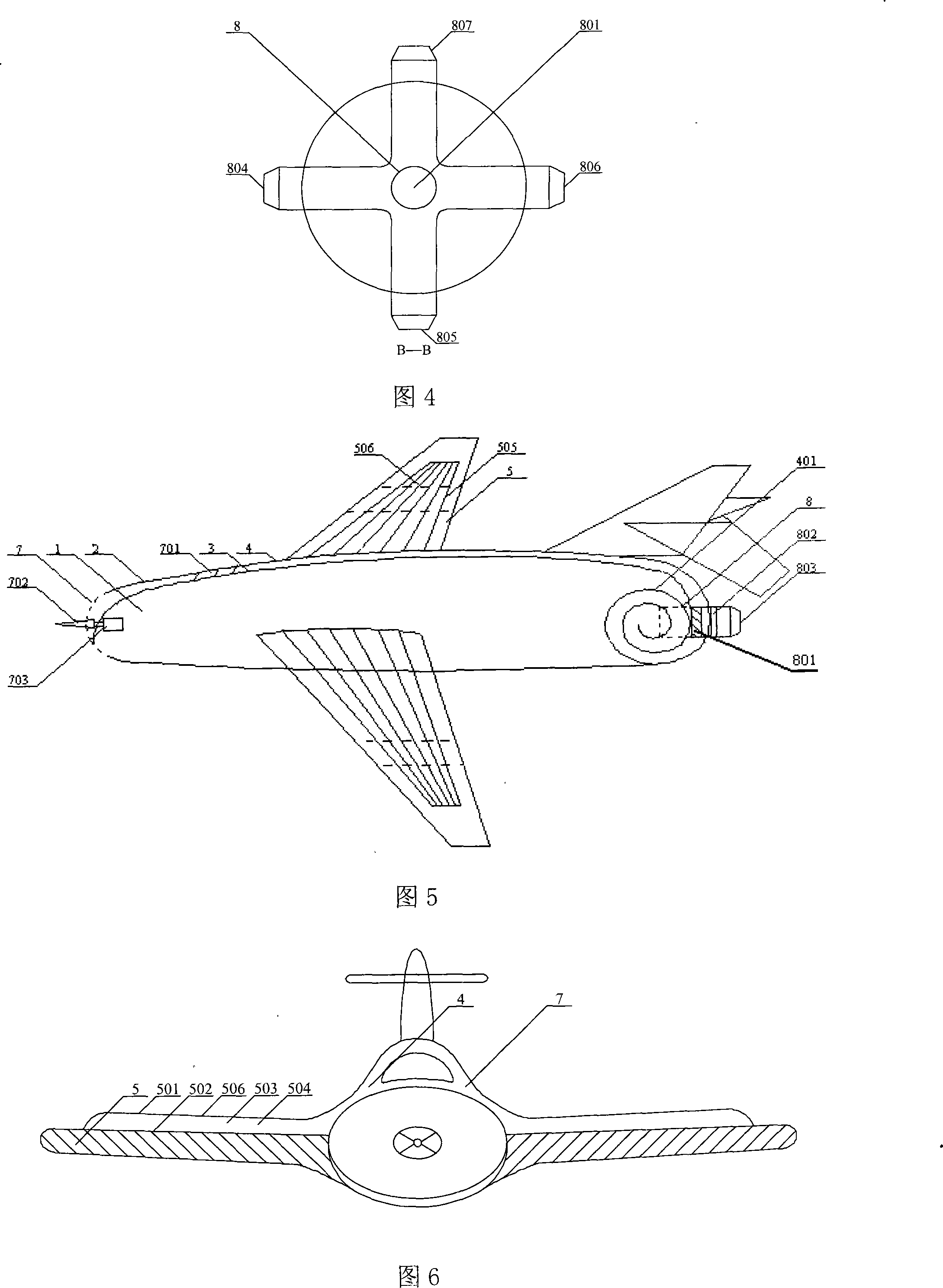

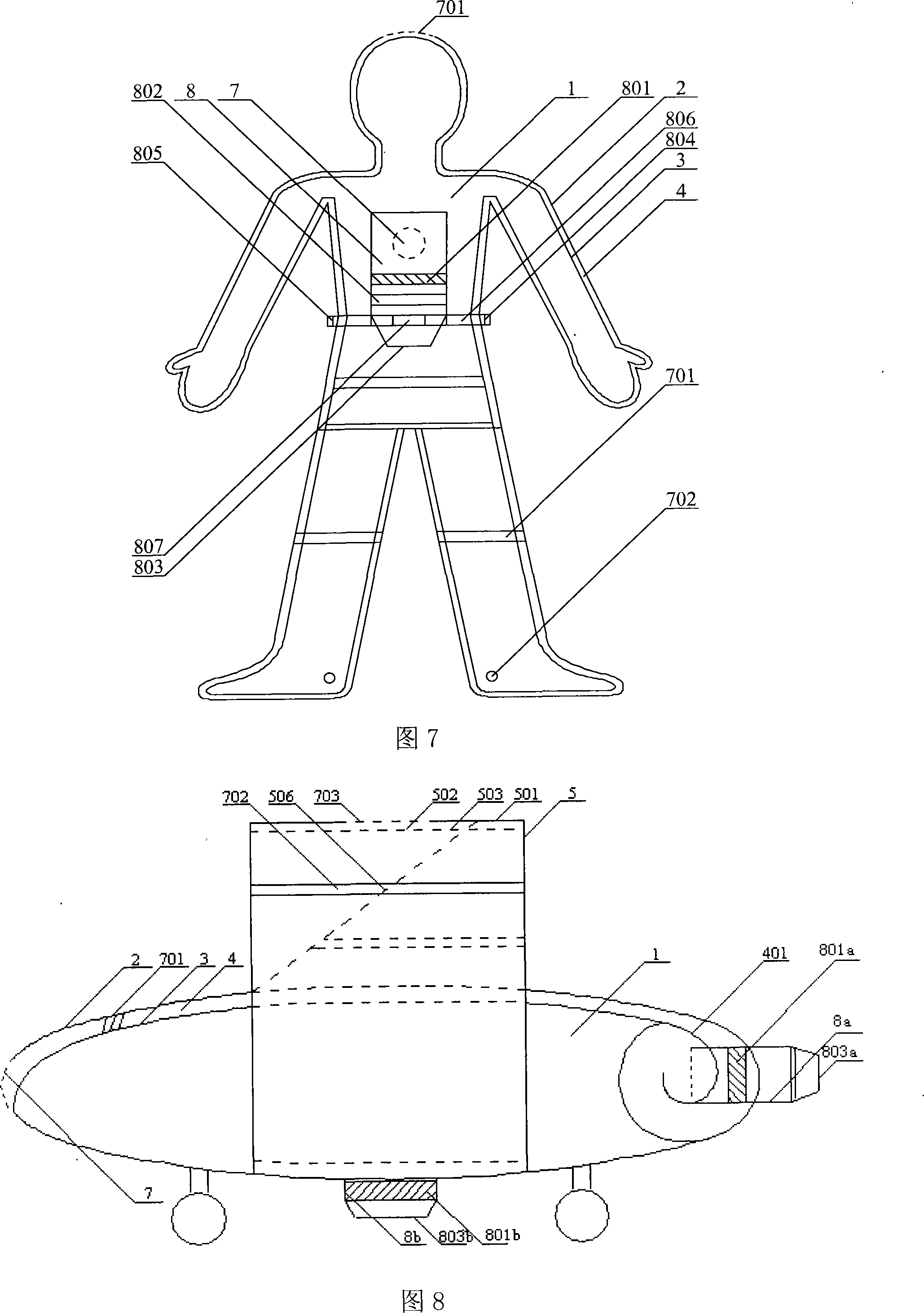

[0062] A spherical aircraft, as shown in Fig. 3 and Fig. 4, differs from Embodiment 1 in that: the aircraft is spherical as a whole; the inner space of the inner shell is divided into an upper semicircle 5 and a lower semicircle 6, and the fluid layer between them The channel 401 communicates with the internal fluid channel 4; the fluid ejection port includes a first fluid ejection port and a second fluid ejection port, wherein the second ejection port is located on the lower semicircle 6, and includes ejection ports facing four directions respectively: the fluid ejection port 804 , fluid ejection port 805, fluid ejection port 806, fluid ejection port 807, each fluid ejection port caliber air outlet end surface can be enlarged, reduced, closed and opened, when necessary, other fluid ejection ports can be closed, and the required fluid ejection port can be opened exhaust. The front end of the fluid ejection port 803 is provided with a second flow regulator, and the second flow ...

Embodiment 3

[0066] An aircraft, as shown in Figure 5 and Figure 6, has the following differences from Embodiment 1.

[0067] The inner fluid channel 4 forms a spiral fluid layer 401 at the rear shell 2 and the inner shell 3 , and the spiral fluid layer 401 can increase the passage of the upper fluid of the fuselage. The fluid ejection port 803 is installed on the end face of the exhaust channel 8 and communicates with the spiral fluid layer 401 , and its ejection port can be enlarged or reduced by adjusting the movable sleeve 802 . A jet engine 801 is fixed inside the outlet cylinder 8 . The internal channel 4 on the entire fuselage and the two layers of high-speed fluid layers on the outer shell 2 are independent and connected to each other, and under the strong suction of the jet engine 801, the fluid flow speed close to the outer shell 2 is faster than the movement of the aircraft The speed, at this time, is such that the various fluid drags approximately equal to the speed of motion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com