Method of increasing fuel cell catalyst stability

A fuel cell and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, battery electrodes, etc., can solve the problems of restricting large-scale production, complex catalyst preparation methods, and high production costs, and is suitable for large-scale production. The effect of novel structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

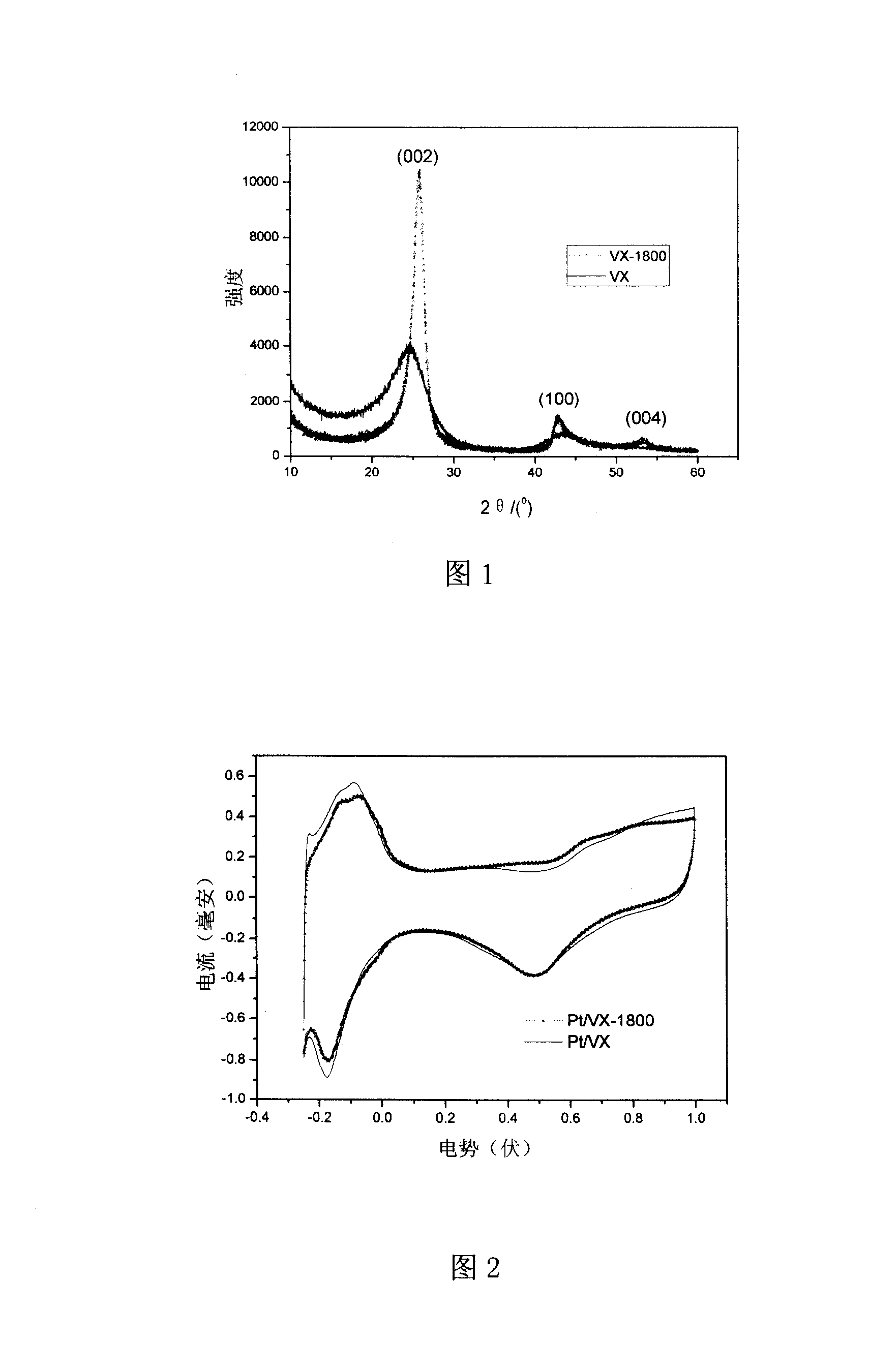

[0026] Place about 200g of commercial carbon powder material Vulcan XC-72 in a high temperature resistant graphite crucible, and put the graphite crucible into an intermediate frequency induction high temperature graphitization furnace for graphitization. Its temperature selection is 1800 ℃. The treatment process is as follows: first evacuate to about 10Pa, then power on to raise the temperature, use manual heating, stop vacuuming when the temperature reaches the holding temperature, and fill the furnace with high-purity Ar gas until the pressure in the furnace is 0.09MPa. And after the end point temperature was constant for 0.5 hours, the sample was cooled to room temperature with the furnace. Using the carbon material as a carrier, a Pt / C catalyst was prepared by a direct reduction method. Figure 1 is the XRD comparison chart of the graphitized carbon carrier and the original carbon powder in this example, and Figure 2 is the cyclic voltammogram of the prepared catalyst.

Embodiment 2

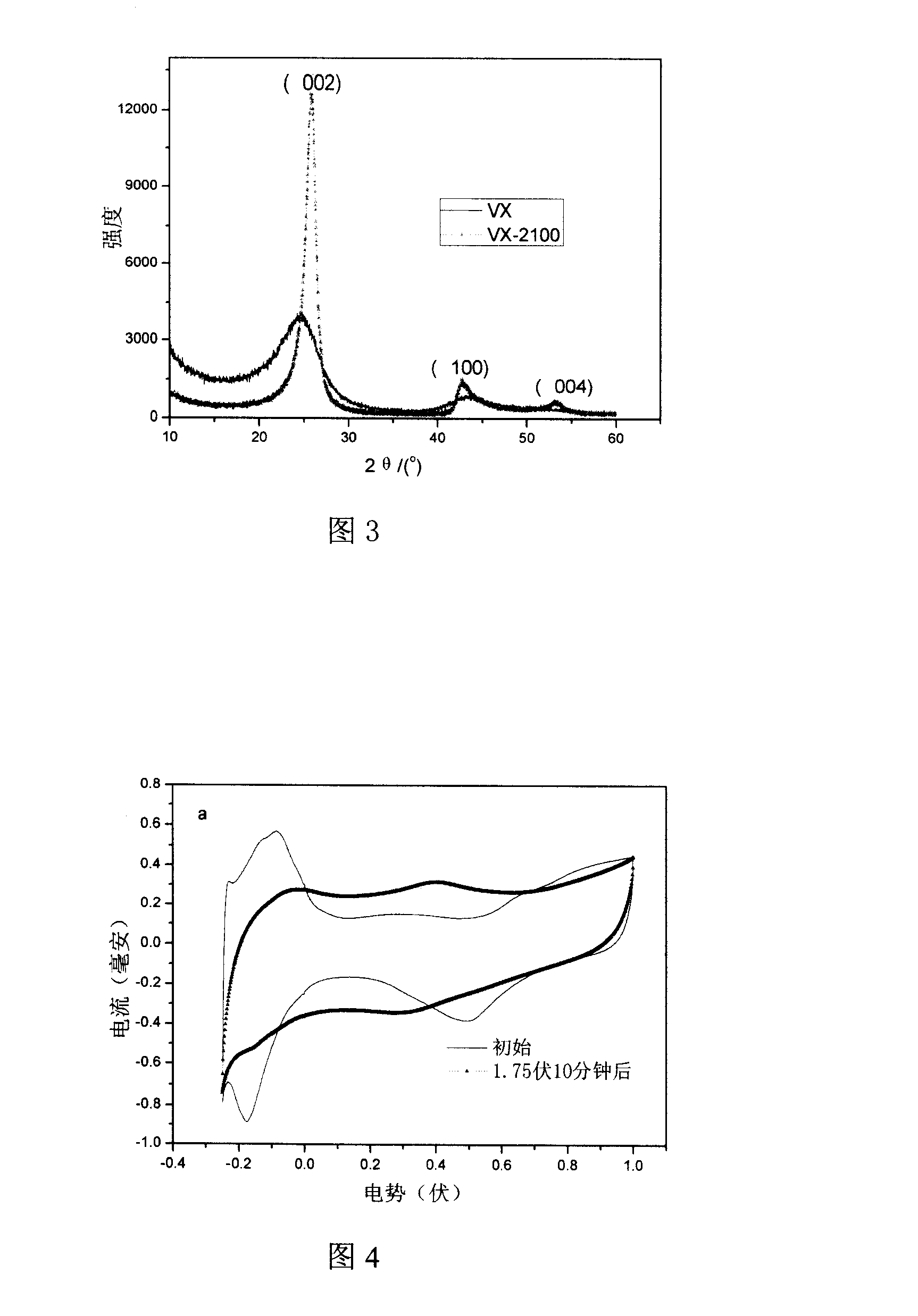

[0028] Place about 200g of commercial carbon powder material Vulcan XC-72 in a high temperature resistant graphite crucible, and put the graphite crucible into an intermediate frequency induction high temperature graphitization furnace for graphitization. Its temperature selection is 2100 ℃. The treatment process is as follows: when the heat preservation temperature is equal to or higher than 2000°C, first evacuate to about 10Pa, then power on to raise the temperature, use manual heating, heat up to 2000°C for 0.5 hours first, stop vacuuming, and fill Ar gas to the pressure in the furnace to 0.09MPa, continue to heat up to the holding temperature of 2100°C. And after the end point temperature was constant for 0.5 hours, the sample was cooled to room temperature with the furnace. Soak the obtained material in 5.0% dilute sulfuric acid for 12 hours, filter and dry. The Pt / C catalyst was prepared by the ethylene glycol reduction method with the dried carbon material as the carr...

Embodiment 3

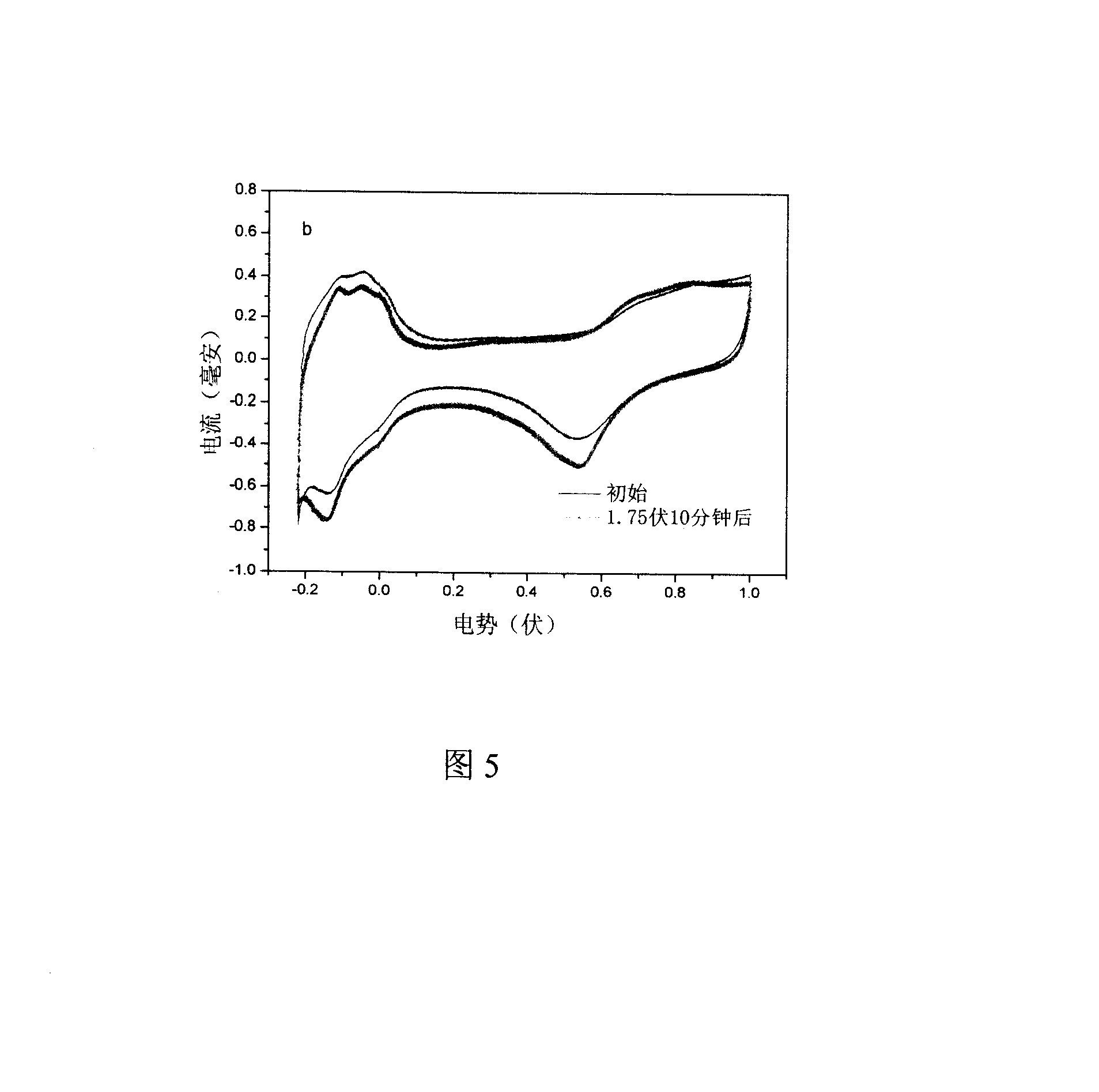

[0030] Place about 200g of commercial carbon powder material Vulcan XC-72 in a high temperature resistant graphite crucible, and put the graphite crucible into an intermediate frequency induction high temperature graphitization furnace for graphitization. Its temperature selection is 2100 ℃. The treatment process is as follows: when the holding temperature is equal to or higher than 2000°C, first vacuumize to about 10Pa, then power on to raise the temperature, use manual heating, heat up to 2000°C for 0.5 hours first, stop vacuuming, and fill the furnace with nitrogen until the pressure in the furnace is 0.09MPa, continue to heat up to the holding temperature of 2100°C. And after the end point temperature was constant for 3 hours, the sample was cooled to room temperature with the furnace. The obtained material was soaked in 5.0% dilute hydrochloric acid for 12 hours, filtered and dried. The Pt / C catalyst was prepared by the direct reduction method with the dried carbon mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com