Pleietrepie counter current falling film evaporator of organic solvent recycle

A falling-film evaporation and countercurrent technology, applied in the field of chemical engineering, can solve the problems of inability to use aqueous organic solvent extraction liquid for evaporation and concentration, large cooling water consumption, large energy consumption of the evaporator, etc., and achieves convenient operation, simple control, and improved evaporation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

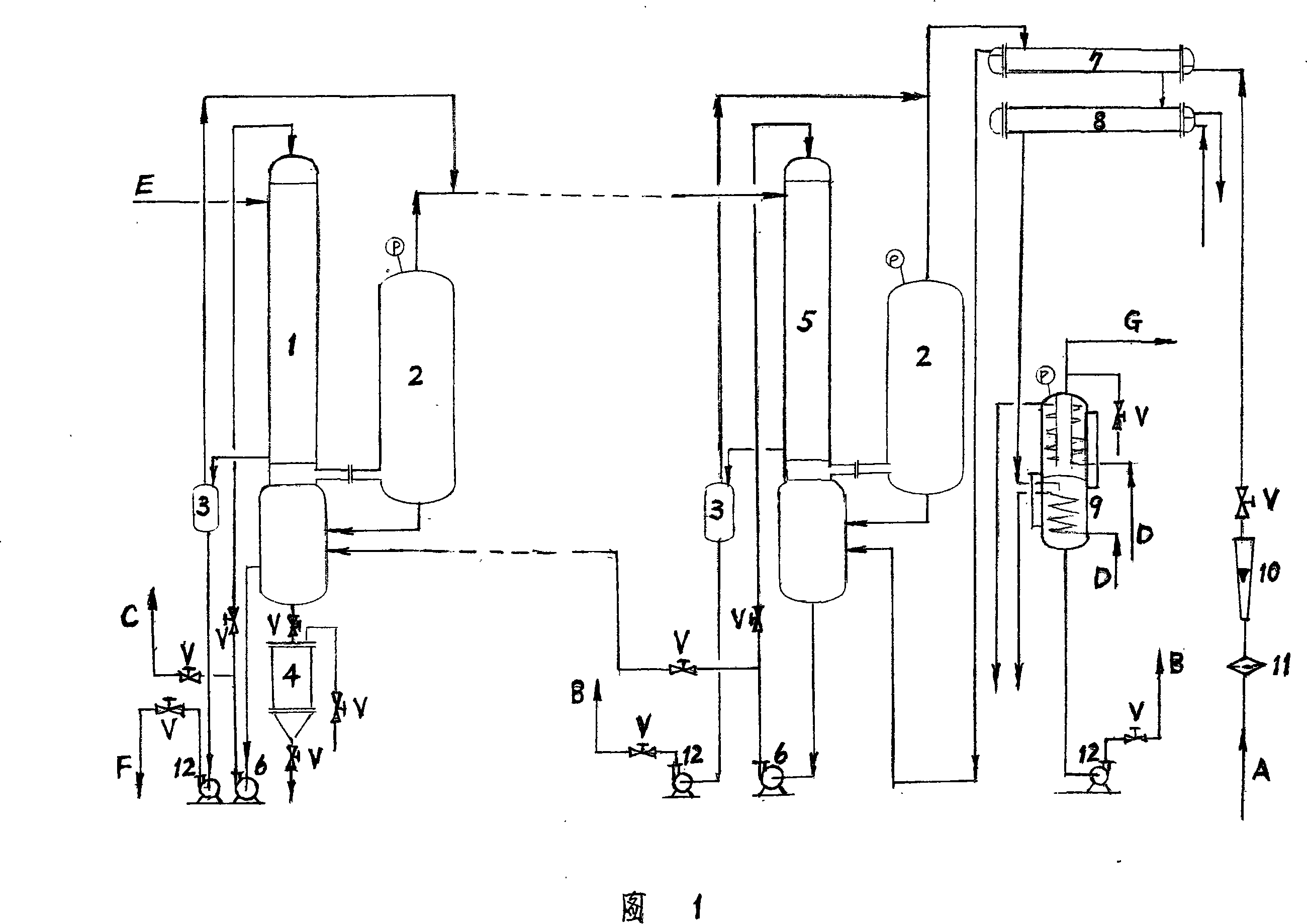

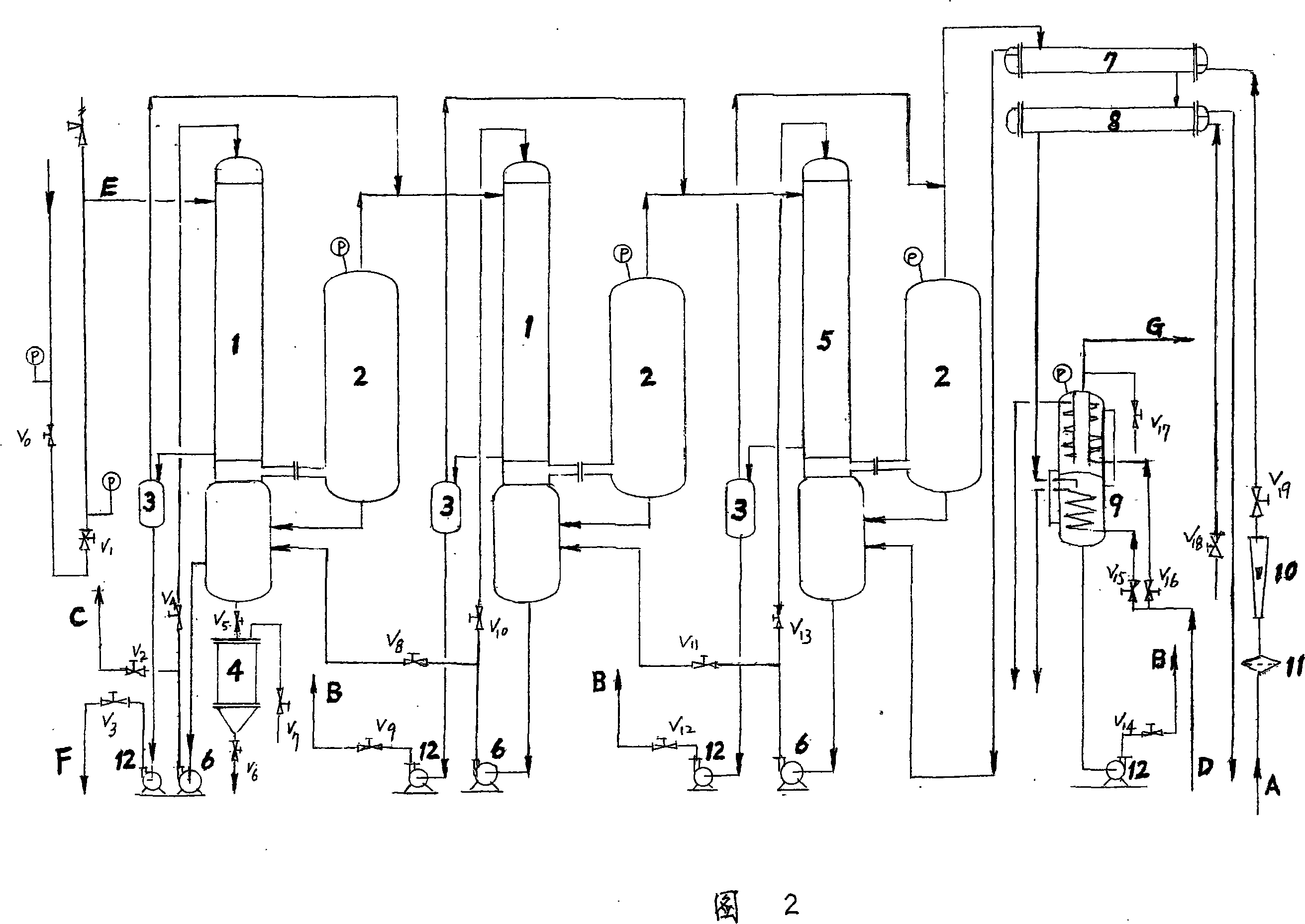

[0050] A three-effect countercurrent falling film evaporation system is adopted, the extractant of the tartary buckwheat flavonoid extract is alcohol aqueous solution, and the recovered organic solvent is the alcohol aqueous solution, and the concentrated solution of the tartary buckwheat flavonoid extract is obtained at the same time.

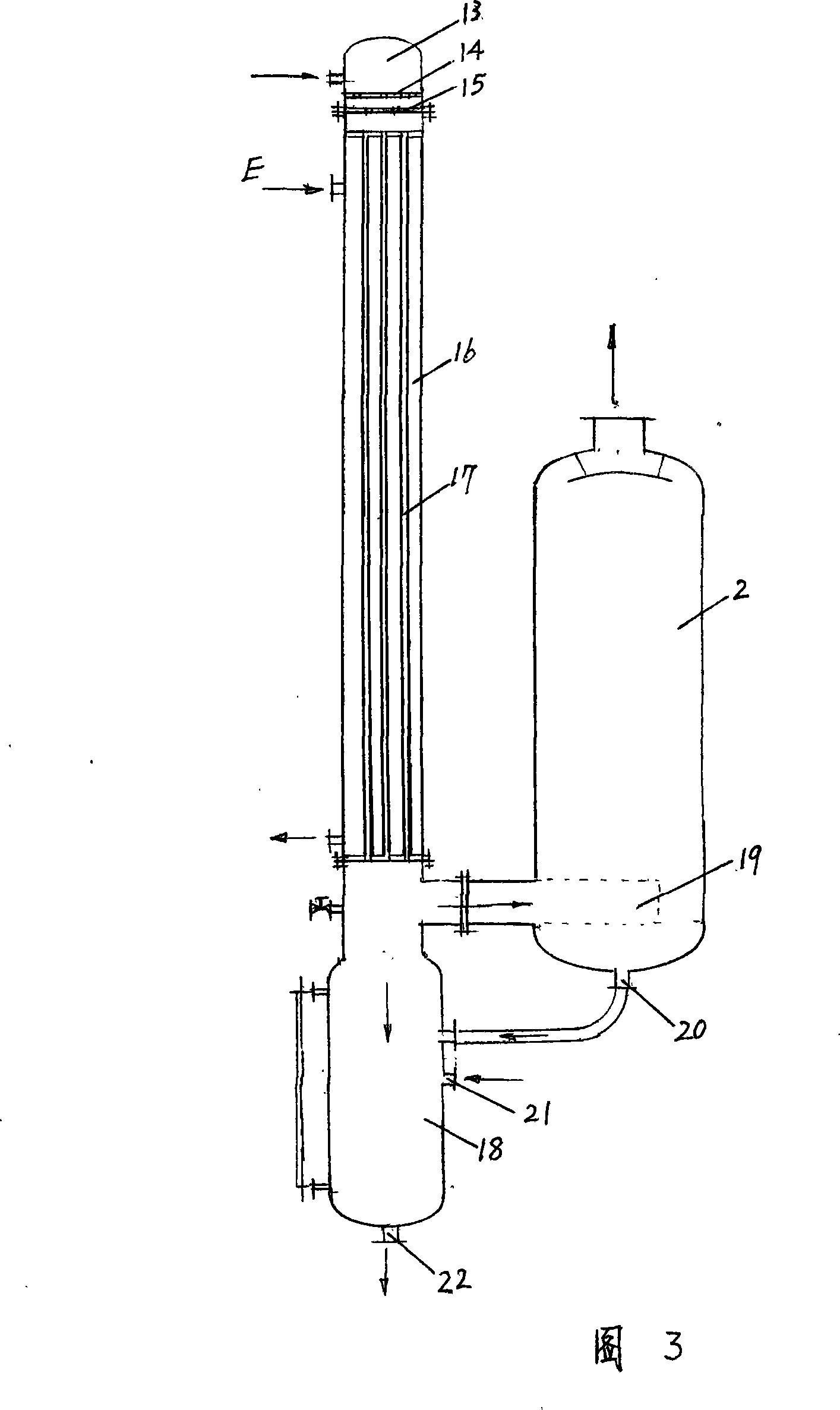

[0051] For the connection relationship between the equipment of the three-effect evaporation system, please refer to attached drawing 2. For the material flow, please refer to the description of the "process flow" in the "instructions" section.

[0052] The organic solvent recovery process of tartary buckwheat flavonoids extract; (see table 1 for operating parameters)

[0053] 1) Loading work

[0054] Check that the system is in a startable state. First, start the vacuum pump to create a vacuum in the system. The tartary buckwheat flavonoid extract (dilute liquid) enters the vapor-liquid separation chamber at the bottom of the third-effect eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com