Air-actuated overflow wind-water combined slag-cooling machine

A slag cooling machine and geomantic technology, applied in fluidized bed combustion equipment, lighting and heating equipment, combustion methods, etc., can solve the problems of unsatisfactory cooling effect of hot slag, insufficient thermal efficiency, short residence time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

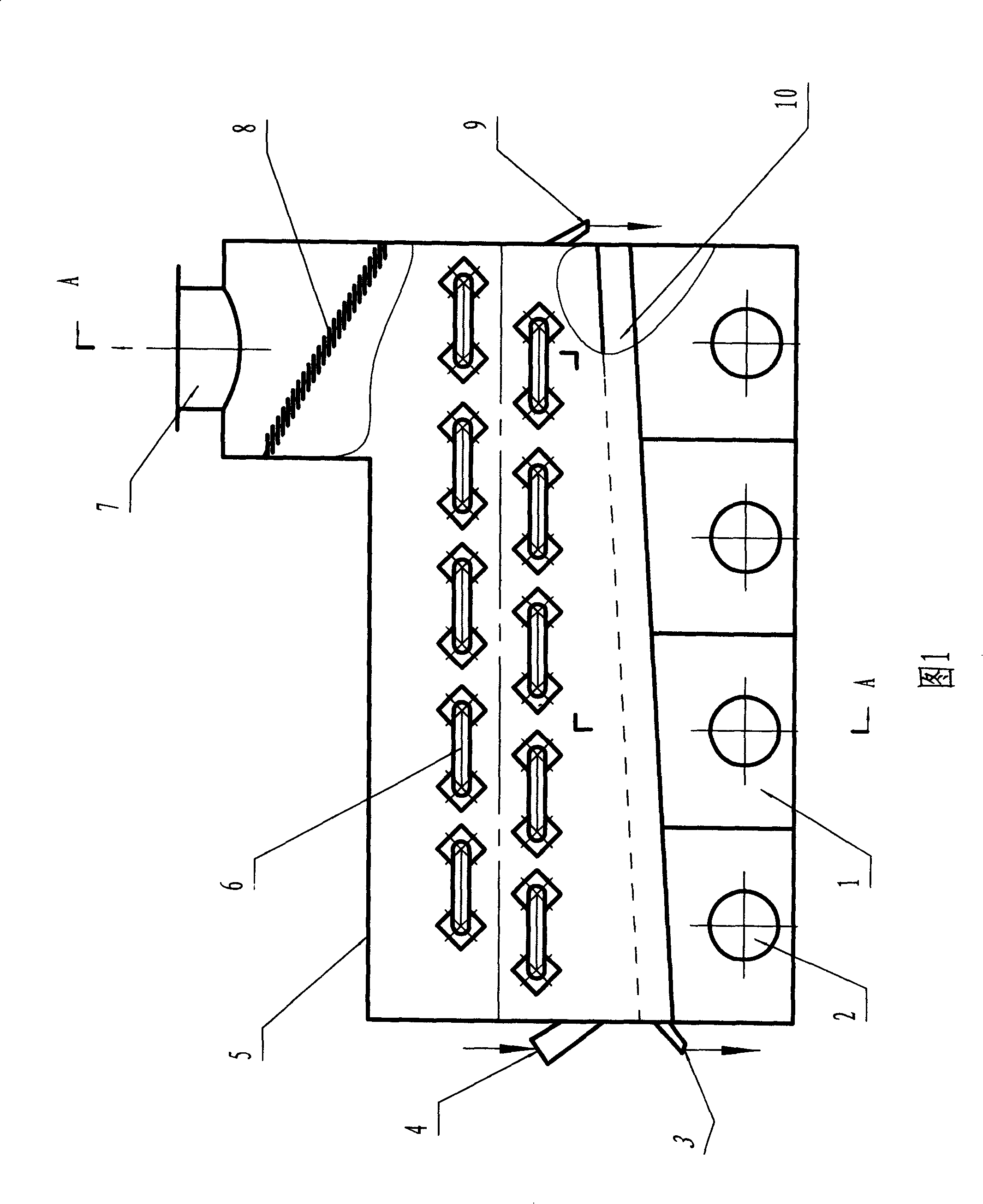

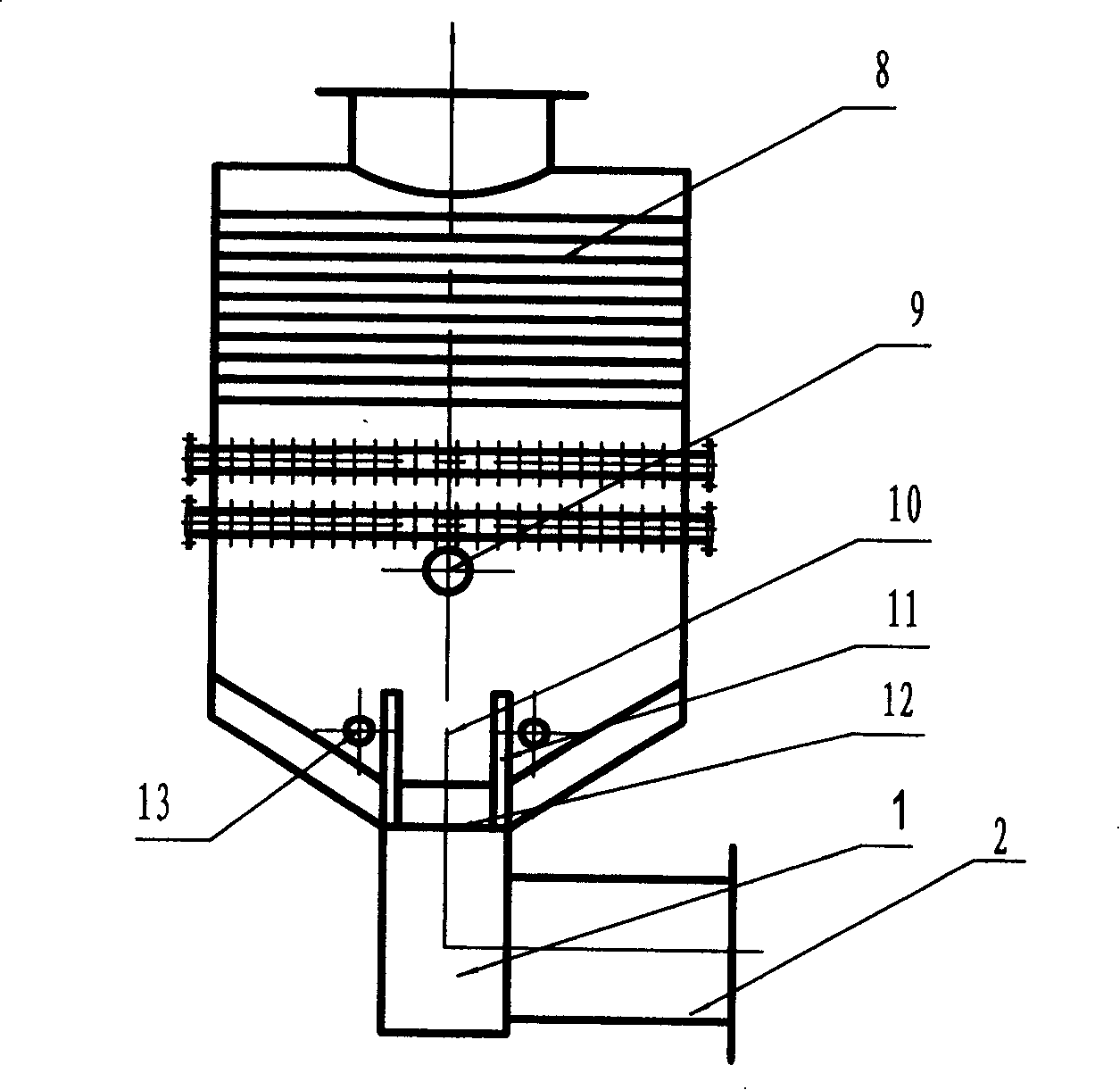

[0016] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

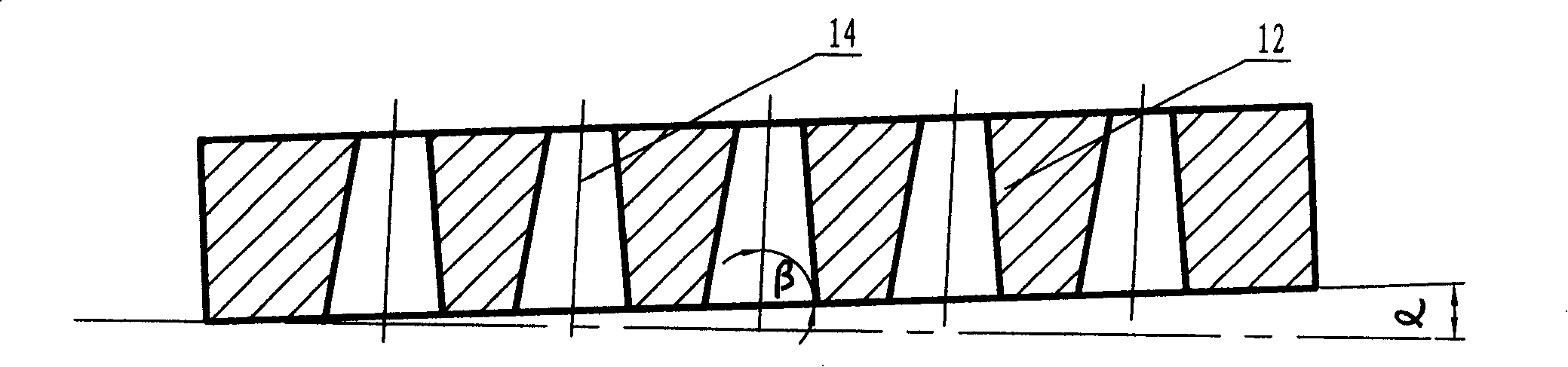

[0017] Fig. 1 is a schematic structural diagram of an embodiment of the present invention. In the figure, there is a housing 5, the top of the housing 5 is provided with a hot air outlet 7, the lower part of the housing 5 is the air chamber 1, the cooling water pipe group 6 is installed above the inner cavity of the housing 5, and the lower part of the inner cavity of the housing 5 is installed Inclined air tank 10, the shell 5 above the low end of the inclined air tank 10 is provided with a slag inlet 4 and an accidental slag discharge port 3, and the shell 5 above the high end of the inclined air tank 10 is provided with a slag outlet Mouth 9. Since the slag inlet 4 is at the low end of the inclined gas tank 10 and the slag outlet 9 is at the high end of the inclined gas tank 10, the hot slag is gradually blown by the cooling wind in the air chamber 1 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com