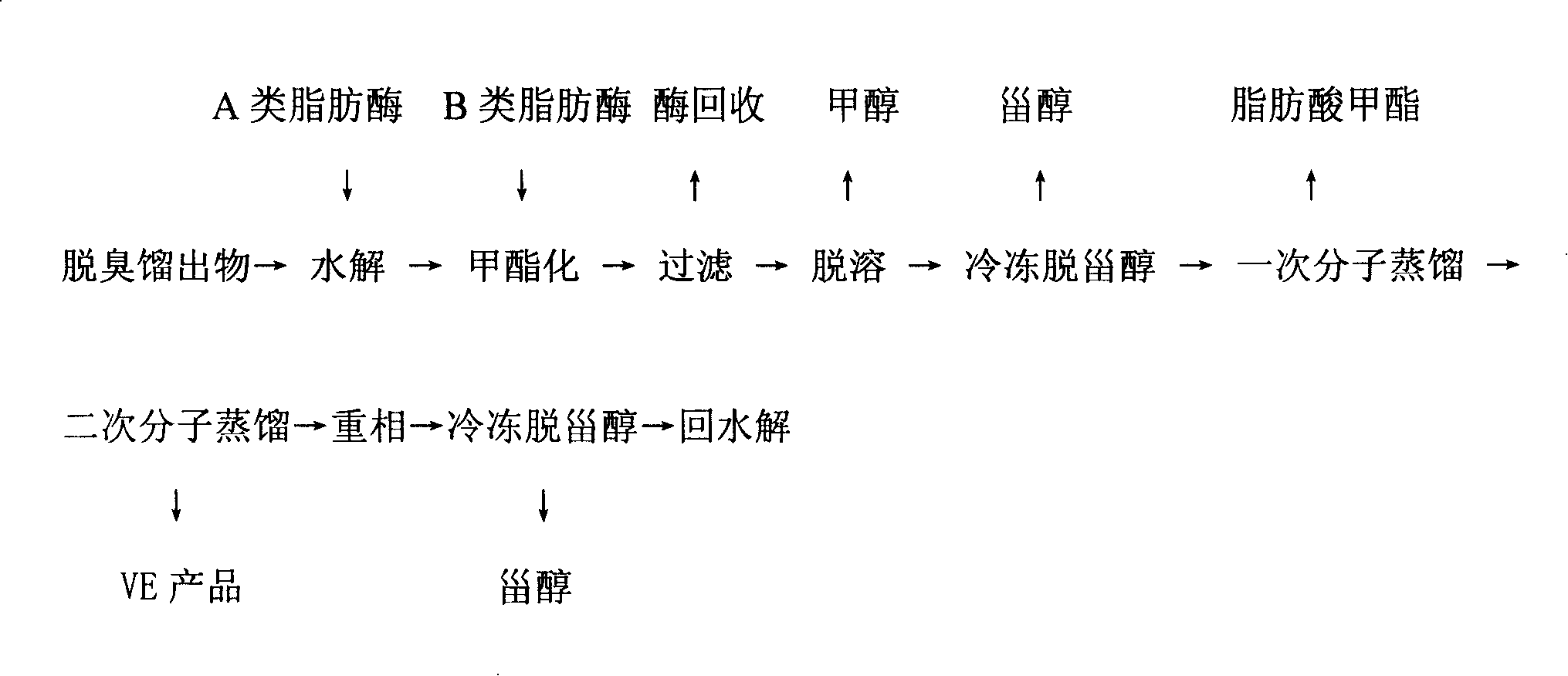

Novel method for extracting natural vitamin E, phytosterol, fatty acid methyl ester by enzyme catalysis and molecular distillation

A technology of fatty acid methyl esters and natural vitamins, which is applied in the field of phytosterols, molecular distillation to extract natural vitamin E, fatty acid methyl esters, and enzyme catalysis. It can solve the problems of cumbersome process, long time, and poor exchange catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0041] A method for extracting natural vitamin E from vegetable oil deodorized distillates, comprising the steps of:

[0042] (1) Hydrolysis, add lipase Lipolase-100T in vegetable oil deodorization distillate, enzyme concentration 1.0% (namely the addition of lipase is 1% of distillate weight), add the water of material equivalent, reaction temperature 55 °C, the hydrolysis reaction time is 10 hours.

[0043] (2) Esterification, the material obtained after being processed by step (1), adding mol ratio is the methyl alcohol of 1: 1, adds lipase Novozym435, enzyme concentration 0.5% (being that lipase consumption is vegetable oil deodorization distillate weight 0.5% of ), the reaction temperature was 35° C., and the reaction time was 2 hours.

[0044] (3) Filtration, suction filtration under the condition of a pressure of 0.05MPa, the lipase is separated from the material and can be reused.

[0045] (4) Precipitation, the material from which the lipase is removed by filtration...

example 2

[0051] A method for extracting natural vitamin E from vegetable oil deodorized distillates, comprising the steps of:

[0052] (1) hydrolysis, add lipase Lipolase-100L in vegetable oil deodorization distillate, enzyme concentration 2.0% (that is the add-on of lipase is 2% of distillate weight), material: water is 1: 1, reaction temperature 50°C, reaction time 11 hours.

[0053] (2) Esterification, the material obtained after being processed by step (1), the addition of methanol with a molar ratio of 1: 1.5, the addition of lipase Novozym735, enzyme concentration 1.0% (that is, the amount of lipase is the vegetable oil deodorization distillate weight 1.0%), the reaction temperature is 45°C, and the reaction time is 4 hours.

[0054] (3) Filtration, suction filtration under the condition of a pressure of 0.06MPa, the lipase is separated from the material and reused.

[0055] (4) Precipitation, the material from which lipase B has been removed by filtration is evaporated to reco...

example 3

[0061] A method for extracting natural vitamin E from vegetable oil deodorized distillates, comprising the steps of:

[0062] (1) hydrolysis, add lipase Lipopex-100T in vegetable oil deodorization distillate, enzyme concentration 3.0% (the addition of lipase is 3% of distillate weight), material: water is 1: 1.5, reaction temperature 55°C, reaction time 12 hours, hydrolysis.

[0063] (2) Esterification, after the material obtained by step (1) is processed, add the methyl alcohol that molar ratio is 1: 1.8, add lipase LipozymeTL IM, enzyme concentration 1.5% (being that lipase consumption is vegetable oil deodorization distillate 1.5% by weight), the reaction temperature was 50° C., and the reaction time was 6 hours.

[0064] (3) Filtration, suction filtration under the condition of a pressure of 0.05MPa, the lipase is separated from the material and reused.

[0065] (4) Precipitation, the material from which the lipase is removed by filtration is evaporated to recover excess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com